The holidays are here! It’s the most wonderful—and busiest—time of the year. If your Christmas wish is for a workshop that rivals Santa’s, LeBlond has got you covered!

Whether you’re looking for a new tool, accessory, or genuine manufacturer part, LeBlond Ltd is a one-stop-shop for all of your machine tool needs. Are you looking for technical advice or on-site support? We do that, too.

LeBlond Ltd is the go-to name in machine tools, parts, and equipment support. While the company began manufacturing metal cutting lathes, we have grown to include so much more.

LeBlond Ltd is the only source for new LeBlond and K.O. Lee manual machine tools. We are also a genuine OEM parts supplier for machine tool product lines from Standard Modern, W.F. & John Barnes, Johnson Press, and Deka Drill. With over 130 years of excellent service, you can trust LeBlond to deliver superior performance and durability.

When you’re working on a big project, you want to know that you can depend on your tools to get it done. That they won’t just get this job done, but the jobs after this one, too. You can rest assured knowing that LeBlond machines will stand the test of time. And when they do need service, or a part needs replacing, LeBlond Ltd is quick to get things up and running again.

Have a question? Give LeBlond Ltd a call at 888-532-5663 (if you’re on a mobile phone, tap the number to call us directly) Monday through Friday, 8:00 AM-5:00 PM ET. Press Option 1 for parts sales, Option 2 for new machines and Option 3 for field service.

Get to Know Us: A History of LeBlond Ltd

LeBlond was founded in 1887 in Cincinnati, Ohio, as the R.K. LeBlond Machine Tool Company by Richard Knight LeBlond. A manufacturer of metal lathes, the business grew steadily through World War II.

In 1981, LeBlond joined with Makino Milling Machine to become the LeBlond Makino Machine Tool Company. In 1996, they changed their name to Makino.

LeBlond Lathe Parts was founded in 1997 to focus on the service and support of all LeBlond lathe equipment. In 1998, they acquired W.F. & John Barnes. As a complete supplier of machine tool equipment and parts, the company rebranded as LeBlond Ltd.

In the years that followed, LeBlond Ltd continued its acquisition strategy. In 1999, they added the Standard Modern lathe service parts business. They acquired the Johnson Press and Deka Drill service parts businesses from South Bend Lathe in 2001.

LeBlond OEM Parts Support

LeBlond Ltd is an Original Equipment Manufacturer (OEM) of genuine equipment parts. Each component for your LeBlond and Standard Modern lathes, as well as K.O. Lee, W.F. & John Barnes, Johnson Press, and Deka Drill tools, are manufactured to their original specifications. That means you get the right component for your exact equipment when you need it — the first time.

Some machine tool parts can become harder to find as a machine ages. This is due to manufacturers choosing to limit support for older machines. Some manufacturers will drop support for machines just five years old! LeBlond Ltd, on the other hand, still provides OEM service repair and replacement parts for machines built as early as 1940.

Common LeBlond Lathe Parts

Are you looking for genuine LeBlond parts? Here are two common ones:

Gear Cluster

Part Number: P01563

The gear cluster is a component of the headstock, specifically the intershaft. The lathe headstock supports and aligns the spindle and its bearings, belts, pulleys, and gearings.

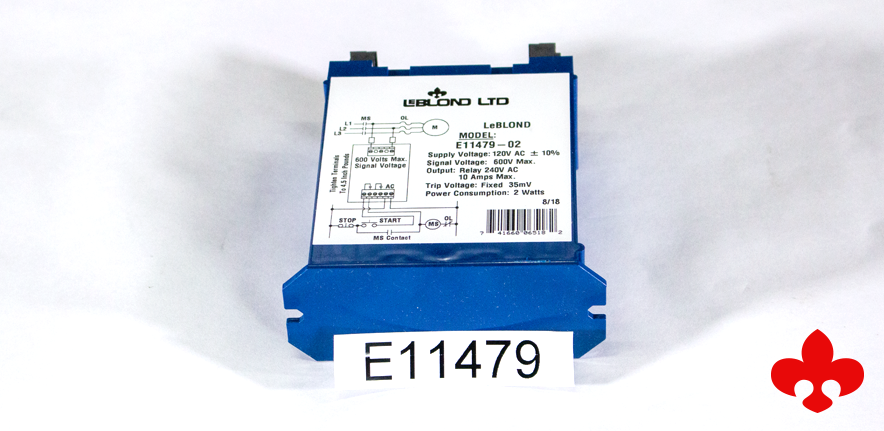

Zero Velocity Module

Part Number: E11479

The Zero Velocity Module (ZVM), or, “The Blue Box,” is a replacement for the original mercury-type zero speed switch that is common on older LeBlond lathes.

For LeBlond OEM parts, request a custom parts quote here, or call (888) 532-5663 and dial Option 1 Monday through Friday, 8:00 AM-5:00 PM ET.

Standard Modern

Standard Modern was founded in 1931 as Standard Machine & Tool in Windsor, Ontario. The Standard Modern parts service business became part of LeBlond Ltd in 1999 to service the over 17,000 installations in North America, particularly in the Canadian and United States military.

Common Standard Modern Lathe Parts

Bevel Pinion

Part Number: SM21245

The bevel pinion is part of the apron on a Standard Modern lathe. It rides the bevel gear to help the apron move down and back while the machine is running.

Crossfeed Nut

Part Number: SM41317

The crossfeed nut stabilizes the crossfeed screw. Both are part of the cross slide and saddle on a Standard Modern lathe.

For Standard Modern OEM parts, request a custom parts quote here, or call (888) 532-5663 and select Option 1 Monday through Friday, 8:00 AM-5:00 PM ET.

K.O. Lee

K.O. Lee is a subsidiary of LeBlond Ltd. It was founded in 1887 by Knute Oscar “K.O.” Lee as a farm machinery sales business and expanded into the machine tools market. LeBlond Ltd acquired K.O. Lee in 2008.

K.O. Lee is best known for surface grinders and tool cutter grinders. LeBlond Ltd sells new grinders and provides OEM parts for older K.O. Lee machinery.

Common K.O. Lee Parts

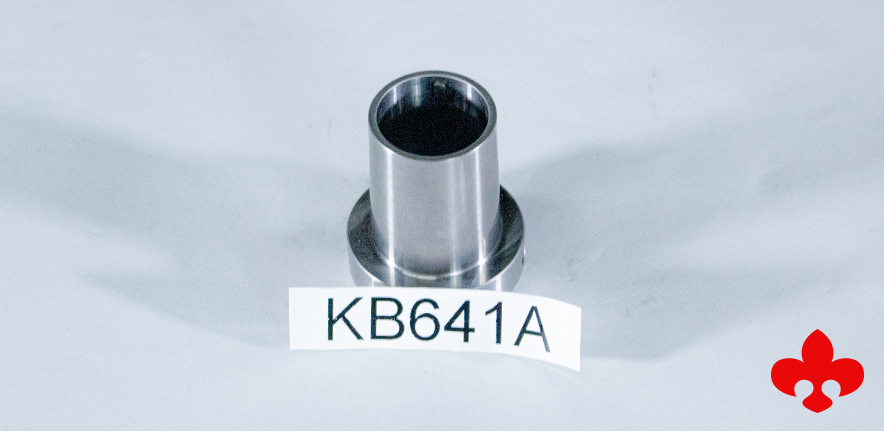

Adapter Collet with Key #11 BS-5C

Part Number: KB641A

The adapter collet with key is a component of a K.O. Lee surface grinder.

Drive Gear

Part Number: KB929L

The drive gear is a component on K.O. Lee surface grinders.

For K.O. Lee OEM parts, request a custom parts quote here, or call (888) 532-5663 and select Option 1 Monday through Friday, 8:00 AM-5:00 PM ET.

Deka Drill & Johnson Press

Deka Drill was started in Illinois by the five Sainati brothers. South Bend Lathe bought the Deka Drill product line in 1968. They discontinued the product line in the early 2000s due to a change in business focus and strategy.

Deka Drill press parts are unique. All models have two important benefits:

- The spindles do not deflect

- The tables efficiently move the workpiece up to the cutting tools to perform a wide variety of operations, including drilling, tapping, dwelling, spot facing, counterboring, and chamfering.

Johnson Press started in Indiana in 1937 as a manufacturer of punch presses. South Bend Lathe purchased the line in the 1960s. The machines were manufactured until the early 2000s when the parts business was acquired by LeBlond Ltd.

LeBlond Ltd acquired Deka Drill and Johnson Press product lines in March 2002 from South Bend Lathe.

Common Deka Drill Parts

Double Universal Driver

Part Number: DKU70

The double universal driver is a component of the drill head.

Driver Gear Shaft

Part Number: DKPT7962MB1

The driver gear shaft is another component of the drill head.

Common Johnson Press Parts

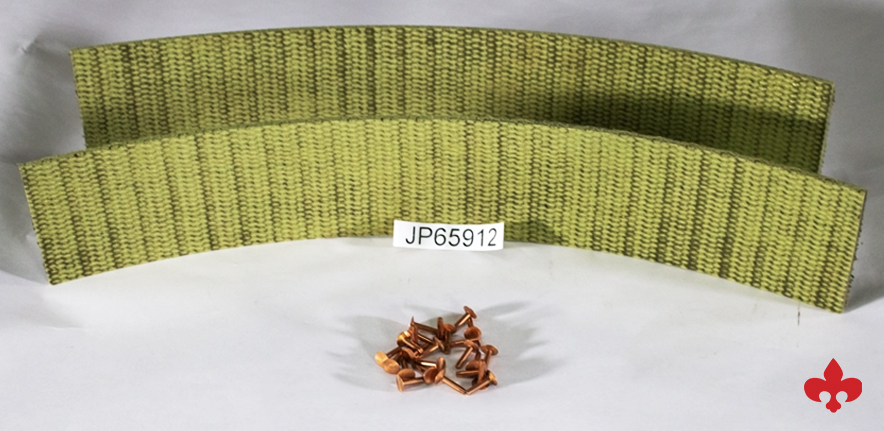

Brake Lining

Part Number: JP65912

These brake linings fit the brake shoe of your Johnson Press machine—one pair per machine. Like brakes for your car, the more you drive (and brake), the faster the linings wear out and need to be replaced.

Lockbolt

Part Number: JP12505

The lockbolt is used on the mechanical clutch on older presses. There is one lockbolt per Johnson Press machine

For Deka Drill and Johnson Press OEM parts, request a custom parts quote here, or call (888) 532-5663 and select Option 1 Monday through Friday, 8:00 AM-5:00 PM ET.

W.F. & John Barnes

The W.F. & John Barnes Company was founded in 1872 as a manufacturer of special machines for the automotive, truck, farm equipment, off-highway, oil and gas, aerospace, defense, marine, and transportation industries. The company was established in Rockford, Illinois. In the 1980s, Acme Precision Products acquired the business and relocated it to Michigan.

Throughout its years of operation, W.F. & John Barnes built a worldwide reputation as a premier machine builder. They did this by engineering transfer lines and medium-to-low volume equipment capable of producing diesel and gasoline engine cylinder liners, connecting rods, crankshafts, flywheels, brake drums, transmission housings, differential housings, and numerous power train components.

W.F. & John Barnes manufactured elite machines until the mid-1980s. In 1998, LeBlond Ltd acquired the Barnes service parts business that now resides near Cincinnati, Ohio.

For W.F. & John Barnes OEM parts, request a custom parts quote here, or call (888) 532-5663 and select Option 1 Monday through Friday, 8:00 AM-5:00 PM ET.

LeBlond Machine Tools

LeBlond has been a leader in manual machine tools for over 130 years. While you may know us for their manual lathes, we aim to be a true supplier of all of your machine needs.

LeBlond expert machine tools include:

Lathes

- For a stellar engine lathe, look no further than the LeBlond RKL manual lathe.

- For jobs where precision is key, check out LeBlond precision high-speed metal lathes or a precision high-speed heavy-duty lathe.

- For bigger projects that require more power, try a RKL heavy duty engine lathe with swings from 22” to 40.”

- For a good educational or gunsmith lathe, look to the RKL-1332.

Mills

The LeBlond CNC Mill has a 9”x48” table and 3-axis CNC Control with fully functioning digital readout (DRO). When using this machine, a machinist can choose to operate it manually or transition to CNC control for jobs that repeat. The CNC Mill is easy to use. No previous programming knowledge is necessary to get it up and running.

The LVM 9”x48” Mill with CNC Control features:

- Available offline software

- Go from sketch to program to finished part in just minutes

- Faster set-ups and shorter run times, resulting in greater productivity and more efficient business

The LeBlond Manual Vertical Mill is economical and easy to operate.

The LVM 9 Series features a 9”x48” table and multiple spindle speed control selections. The LVM 10 Series models have a 10”x50” and 10”x54” tables, and the LVM 12 Series model has a 12”x58” table.

A LeBlond Vertical Mill Machine has all the precision and durability you have come to expect from LeBlond lathes, in a mill.

Saws

The LeBlond Metal Band Saws are built with versatility and power.

The Horizontal Metal Band Saw has a variable speed setting that allows an operator to set a low speed for materials like steel and brass, and a higher speed for aluminum. Swiveling vises allow for varying cut angles. Features a blade size of 1.062” x .035” x 130.”

The LeBlond Vertical Band Saw also has the power to handle demanding jobs. It also has a variable speed setting and a blade size of 0.629” x 0.118” x 153.”

Standard accessories include:

- Saw blade butt welder with integrated annealing unit

- Blade shear and grinder

- Brush for cleaning lower wheel drive

- Low-voltage LED work light

Both LeBlond band saws are equipped with electrics of 230V/460V/3PH/60Hz and have a One-Year Parts and Service Warranty.

Drill Press

We’re ready to call it: the LeBlond LDP-25VS is the best drill press. It is an absolute inverter variable speed drilling machine.

Drill holes as well as perform sanding, honing, and polishing operations. Features continuous variable transmission that allows for a wide speed range and ability to change speeds while the machine is running.

The LDP-25VS is equipped with key standard features for any job, including:

- Digital Tachometer Display

- Tapping System

- LED Work Light

- Safety Guard Kit with Shut Off Micro Switch

Machine Tool Suite

The LeBlond Suite includes a selection of five machine tools to complete any workshop, classroom, or tool room, including:

- RKL-1332G Lathe

- LVM 9”x48” Vertical Knee Mill

- LHS-10 Horizontal Band Saw

- LVS-50 Vertical Band Saw

- LDP-25VS Drill Press

Need something a little different? The LeBlond Suite is fully customizable. Each machine is also protected by a One-Year Parts & Service Warranty.

K.O. Lee Machine Tools

LeBlond Ltd is the only source for K.O. Lee surface grinders and cutter grinders as well as expanding mandrels.

K.O. Lee Surface Grinders

K.O. Lee manual and automatic surface grinders deliver the same accuracy of much more expensive machines. They are economical and easy to operate.

Manual surface grinding is achieved by running the table left and right with one hand wheel while cross-feeding with the other hand wheel. Automatic surface grinding allows the table to run left and right automatically while cross-feeding automatically.

Here’s what you can expect from a K.O. Lee surface grinder:

- Precision grinding spindle comprised of Class 4 super precision angular contact bearings suitable for heavy grinding. The spindle is directly coupled with the motor, ensuring spindle run out accuracy of less than 0.002mm.

- Machine construction of main components, including the base column and saddle, are high-quality double wall Meehanite cast iron that has been stress relieved to ensure rigid stability.

- Both longitudinal and cross slideways are precisely hand-scraped and laminated with Turcite-B, providing smooth travel and even lower wear.

- An automatic lubrication system is standard on all slideways and leadscrews, ensuring smooth travel and minimizing wear.

- A comprehensive control panel makes it easy to operate your machinery.

K.O. Lee Cutter Grinders

A K.O. Lee cutter grinder can keep milling cutters and tool bits sharp. The KOL-40M or 60M Tool and Cutter Grinder features dedicated fixtures for cylindrical grinding where complex angles can be ground.

The table can move longitudinally and laterally. It can be easily controlled from fine to rapid feed range. The wheelhead can be tilted easily to ±15° and swiveled 360°, making it easy to set rake and relief angles.

K.O. Lee tool and cutter grinder standard features include:

- Electrics: 230V/3PH/60Hz with other voltages available

- Wheel guard holders (long and short)

- Grinding wheels (7 sizes)

- Diamond dresser holder

- Workhead spindle center

- Center gauge

K.O. Lee Expanding Mandrels

K.O. Lee expanding mandrels save time and money. Because they expand, they can replace multiple individual mandrels. Like a multi-head screwdriver, expanding mandrels provide a variety of utilities. Expanding mandrels help maintain a positive grip on heavy jobs. They prevent slip and chatter and hold thin sleeves and bushings without distortion.

LeBlond Machine Tools Accessories

There’s no need to source from multiple vendors when getting your own workshop up and running. LeBlond Ltd has everything you need for your machine tools—even machine tool accessories!

Here are some of the key accessories LeBlond Ltd has to offer:

- Digital Readout Packages that feature all the essential functions for milling, boring, turning, grinding, and general machining operations. The unit is housed in a rugged, ergonomically designed casting with membrane keypad. A safe, low voltage power supply and intuitive message window with easy-to-read LEDs.

- K.O. Lee Abrasive Wheel Dressers allows you to dress your grinding wheel in just a few seconds.

- The K.O. Lee Bench Center and Surface Plate allows for accurate means of inspection of all types of work. Pieces can be mounted between centers, in V-rests, or on a precision ground surface plate.

LeBlond Ltd for All of Your Machine Tool Needs

After over 130 years of steady expansion, LeBlond is continuing to innovate the machine tools business. Whether you’re starting a business, outfitting a classroom, or setting up a workshop, LeBlond Ltd can help you get started. And they’ll be there every step of the way for the life of your machine!

2021 will be an exciting year for us. We will continue to release new machine tool lines including a gamechanger that will radically transform how people perceive our brand. Stay tuned!

Have a question or inquiry? Give LeBlond Ltd a call at (888) 532-5663 Monday through Friday, 8:00 AM-5:00 PM ET or get a custom quote.