Table of Contents

- Quick History Between K.O. Lee and LeBlond

- The Benefits of the K.O. Lee Surface Grinder Machines

- Common K.O. Lee Surface Grinder Parts

- Popular K.O. Lee Surface Grinders

- Replacing the Timing Belt on a Surface Grinding Machine

- Step-By-Step Instructions for the Timing Belt Replacement on the S612 Model

- K.O. Lee Surface Grinder Timing Belt Best Practices

- K.O. Lee Parts & Service Explained

- Key Takeaways

TL;DR

LeBlond LTD, a Cincinnati-based machine tool supplier, provides OES (Original Equipment Supplier) parts for K.O. Lee grinders. This post details K.O. Lee parts including common replacement parts and information on service issues such as replacing the timing belt on a common K.O. Lee surface grinder model.

Quick History Between K.O. Lee and LeBlond

K.O. Lee is a subsidiary of LeBlond. Knute Oscar “K.O.” Lee founded his company in 1887 as a farm machinery sales business and expanded into the machine tools market over the years. In 2008, LeBlond acquired the K.O. Lee Company.

The K.O. Lee brand is most known for surface grinders and tool cutter grinders. LeBlond sells new grinders and provides OES parts for vintage K.O. Lee machinery.

Let’s first discuss surface grinders and KO Lee surface grinder parts.

The Benefits of the K.O. Lee Surface Grinder Machines

A K.O. Lee manual surface grinder is designed to provide precision grinding for flat surfaces. This machine is commonly used in tool rooms, machine shops, and manufacturing facilities for tasks such as grinding metal parts, sharpening tools, and achieving fine surface finishes.

These grinders may include various features and options depending on the model and specific requirements.

Moving on to the replacement parts side…

Common K.O. Lee Surface Grinder Parts

- Wheelhead: this houses the grinding wheel and can be adjusted vertically and longitudinally for precise grinding.

- Workholding: such as magnetic chucks or precision vises that securely hold the workpiece during grinding.

- Controls: to adjust grinding parameters, such as wheel speed and feed rate, to achieve the desired results.

- Coolant System: to control the heat generated during grinding and improve surface finish.

Here are K.O. Lee surface grinder parts that LeBlond frequently sells.

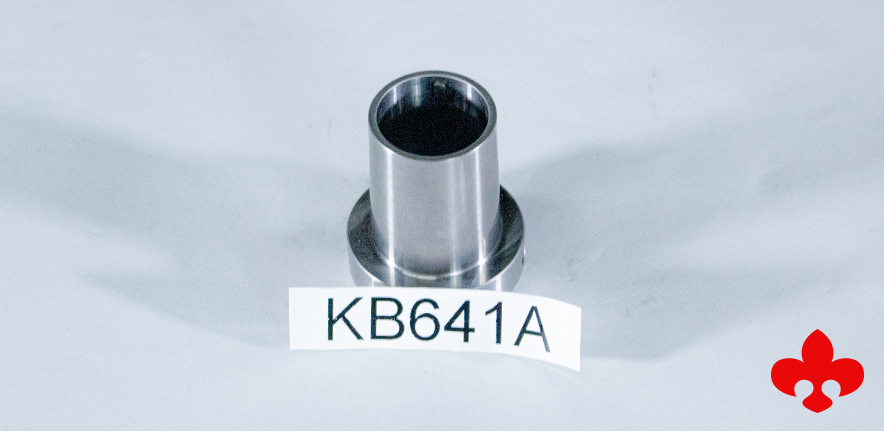

K.O. Lee Part: Adapter Collet with Key

Part Number: KB641A

The adapter collet with key is a component of a K.O. Lee surface grinder. It allows you to use tooling or workpieces with a keyway in machines or tool holders that require a key for proper alignment and secure clamping. Plus, this part provides a secure and reliable connection between the tooling or workpiece and the machine or tool holder.

K.O. Lee Part: Drive Gear

Part Number: KB929L

The drive gear transmits rotational motion from the motor to the grinding wheel spindle. It plays a key role in driving the grinding wheel and enabling grinding operations.

K.O. Lee Part: Miter Gear

Part Number: KBA924-1

The miter gear is used as a right-angle drive where high efficiency is required to transmit motion and power between the right angle (90°) and intersecting shafts at varying speed ratios.

K.O. Lee Part: Cross Feed Screw

Part Number: KS930SF1

The cross-feed screw is a table component on a K.O. Lee surface grinder. Some of the cross-feed screws have changed in size over the years. Ring belts fit most K.O. Lee Surface Grinding machines and timing belts as well. If you’re using a K.O. Lee Grinder machine, it’s recommended to check whether you need to change the cross-feed screw.

Let’s have a look at some in-demand K.O. Lee Surface Grinders to have a better understanding of these machines.

If you want to order parts for your machine(s), please click the button below. 👇

Popular K.O. Lee Surface Grinders

The K.O. Lee S618 and the S718 models from the late 1970s and early 80s are popular machines. They’re pretty similar in all parts besides the cross feet screws, cross feet screws and nuts.

While popularity can vary depending on specific needs and industry preferences, here are a few notable ones:

K.O. Lee S718H

- This model is known for its compact size and versatility.

- It features a 7″ x 18″ grinding capacity, making it suitable for small to medium-sized workpieces.

- The S718H is often favored for its precision, ease of use, and reliable performance.

K.O. Lee S714

- The S714 is a popular choice for its sturdy construction and high-quality grinding capabilities.

- It offers a 7″ x 14″ grinding capacity, suitable for a wide range of grinding tasks.

K.O. Lee S718

- The S718 is another well-regarded model in the K.O. Lee lineup.

- It features a larger grinding capacity of 7″ x 18″, accommodating larger workpieces.

- The S718 is known for its precision, smooth operation, and robust build quality.

K.O. Lee S718S

- The S718S is a surface grinder that offers a 7″ x 18″ grinding capacity.

- It is equipped with a variable-speed grinding spindle, providing greater flexibility for different materials and applications.

- The S718S is appreciated for its versatility, reliability, and ability to achieve excellent surface finishes.

Now that we’ve covered common parts and the most popular K.O. Lee Surface Grinders, let’s have a look at common service issues like replacing a timing belt, the instructions, safety precautions, and more.

Replacing the Timing Belt on a Surface Grinding Machine

Timing belts have various functions such as driving the grinding wheel, controlling the movement of the workpiece or table or powering other mechanisms within the machine.

Changing the timing belt is a frequent service issue on a surface grinder. Let’s discuss the process of the S612 model that is detailed in THIS PDF with instructions and machine and parts diagrams.

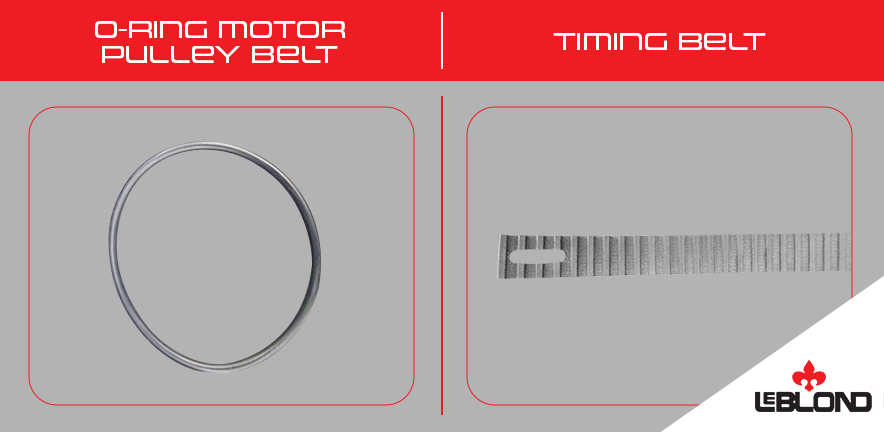

Surface Grinder Timing Belt Components

Timing belts are typically referred to by their specific purposes, such as grinding wheel drive belts, cross-feed belts, or longitudinal feed belts. The timing belt is about 2 1/2 feet long and the O-rings are about 10” around.

The O-rings or belts work as a motor pulley. There are six O-rings that run the machine off the motor. The other parts are the table screw and the cross-C screw with a 39 Index number on the above PDF. This component moves the table horizontally.

Next, let’s have a look at a quick guide on how to replace the timing belt. It’s crucial to assess your timing belts’ lifespan to avoid further damage. Also, track updates on your K.O. surface grinder before starting with your timing belt replacement.

Step-By-Step Instructions for the Timing Belt Replacement on the S612 Model

We’ll focus on some general procedures.

Preparation

- Ensure the machine is turned off and unplugged from the power source.

- Remove any debris or obstructions from the work area.

- Gather the necessary tools, replacement timing belts, and any additional components required.

Accessing the Timing Belt

- Identify the location of the timing belt on the machine. It is usually located in the power transmission system or near the motor.

- You may need to remove protective covers or panels to access the timing belt.

Loosening Tension and Removing the Old Belt

Machines with transmissions on the left side:

- Loosen Lock Nut No.47, then loosen screw No.46. Remove screws No.44 at Clamp Block No.36 which holds the belt in place, and drop the belt end.

- Two people need to lift the table up and set it on its backside on two ½” blocks of wood placed on the rear saddle way extensions. Before lifting the table, run the grinding wheel head to the top of its travel.

- Loosen and remove screws No.44 at Clamp Block 37. Remove the old belt and install a new belt by the reverse process. The feed belt through Transmission Bracket No. 38 has been shown in the PDF linked above.

- Re-attach the belt to Clamp Block No.36 and the retention belt to approximately ¼” belt depression by using a finger test.

Machines with transmissions on the right side:

Reverse the above procedure, working first from the right end of the machine where the tension screw is located.

Adjusting Tension and Securing the Belt

- Ensure the belt is properly tensioned but not overly tight, as excessive tension can lead to premature wear or damage.

- Double-check the belt’s alignment and make any necessary adjustments.

- Securely tighten any fasteners or securing mechanisms that hold the timing belt in place.

Final Checks and Testing

- Reinstall any removed protective covers or panels.

- Ensure all tools and equipment are removed from the work area.

- Plug the machine back into the power source.

- Test the machine to verify that the timing belt functions correctly and the machine operates smoothly.

K.O. Lee Surface Grinder Timing Belt Best Practices

Timing belts ensure precise synchronization between the engine’s camshaft(s) and crankshaft. This coordination ensures that the valves open and close at the correct time in relation to the movement of the pistons.

Proper synchronization leads to optimal engine performance and efficiency. They are generally low maintenance compared to other power transmission systems. They do not require lubrication and are typically self-contained within the engine or machinery, eliminating the need for external maintenance.

While timing belts offer numerous benefits, they do have a limited lifespan and require periodic replacement according to the manufacturer’s recommendations. Neglecting timing belt replacement can result in belt failure and potential damage to the engine or machinery.

K.O. Lee Parts & Service Explained

We hope this information has helped you with K.O. Lee parts and specific surface grinder service questions.

If you have any specific questions about the timing belt replacement, please leave a comment and we’ll be happy to help you.

Don’t wait until the last minute, order K.O. Lee parts NOW!

Service your reliable K.O. Lee machinery with affordable OES parts and keep your machine running reliably.

If you need K.O. Lee parts, click or tap here.

Or you can call us at (888) 532-5663 and select Option 1.

We look forward to hearing from you!

💡 Key Takeaways

- K.O. Lee Surface Grinders are designed to provide precision grinding for flat surfaces

- The Adapter Collet with Key #11, Drive Gear, Miter Gear, and Cross Feed Screw are some common parts for K.O. Lee Surface Grinders

- The K.O. Lee S718H, S714, S718 and S718S are popular equipment manufactured in the late 1970s and early 80s

- Replace your surface grinder timing belt to avoid failure and potential damage to your equipment

- Always check your manual for specific instructions or updates on how to replace your timing belt or other equipment parts

I need to know what size collet is used on K.O. Lee knockout E842 I bought a set of ER 25 and a ER 32 collet. One is too small and the other is too big. I need some help to find out what to do. Thank you for your time is this matter.

Edward, thanks for your comment. Someone will contact you about your machine. For immediate service, call LeBlond at 888-532-5663.

WE OWN A K.O.LEE MODEL S 714H HYDRAULIC SURFACE GRINDER S/N 26569-7E

IS THIS A SINGLE AXIS HYDRAULIC MACHINE ( TABLE LONGITUDINAL ONLY)

OR DOES IT ALSO HAVE AUTO CROSSFEED CAPABILITY ?

PLEASE ADVISE THANK YOU VERY MUCH .

MIKE TERRY

BOSTON MACHINERY INC. 978-532-1112 CELL PHONE # 978-257-0435

Thanks for your question Mike. Someone will contact you. For immediate service, call 888-532-5663 Option 1.

Please provide price and availability of parts for a K.O. Lee A 600 grinder.

A 626 Shaft and gear to elevate motor

A 626B 2 pinion gears

A 229 column nut

David, thanks for your query. Someone will contact you. For immediate service, call 888-532-5663.