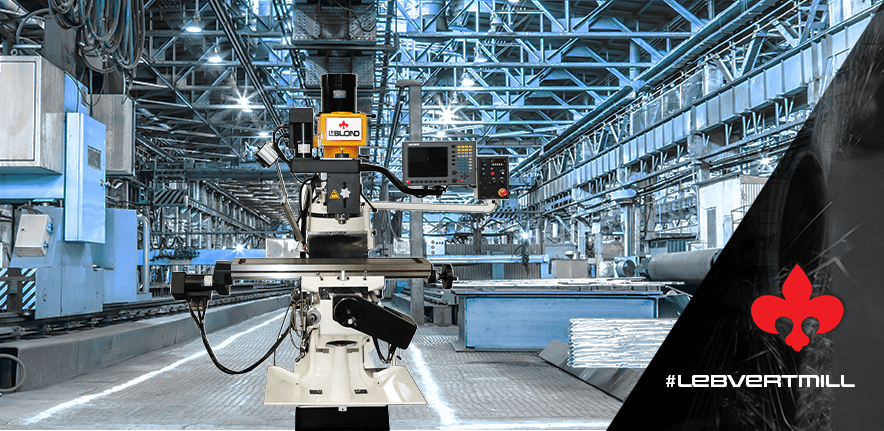

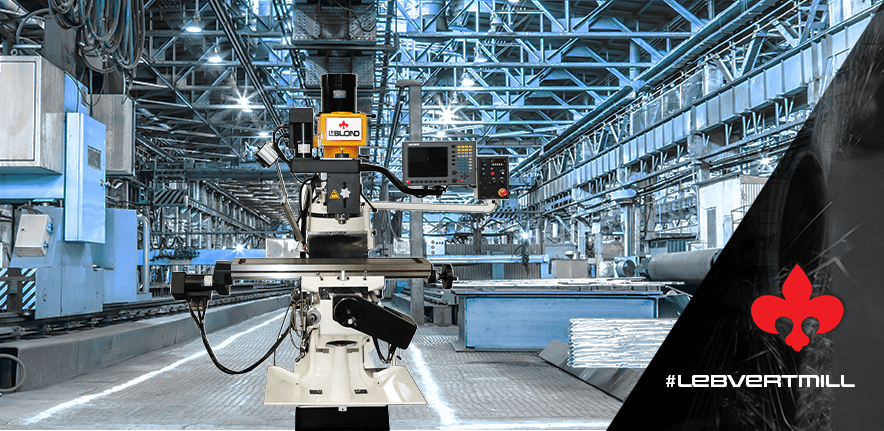

by Michael Barnes | Oct 17, 2023 | Product Information

Table of Contents What is a Vertical Milling Machine? Horizontal vs. Vertical Milling Machines Reason #1: Faster Feeds & Speeds Reason #2: Enhanced Precision & Accuracy Reason #3: Multiple-Axis Capability Overview of LeBlond Vertical Mills Contact LeBlond for...

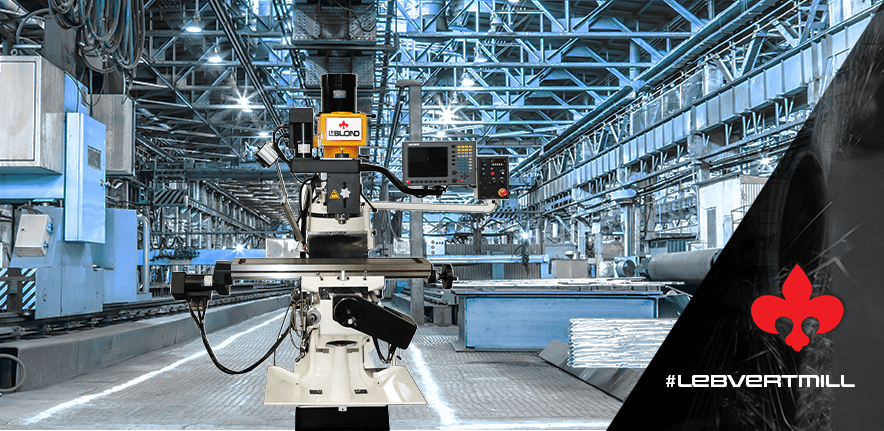

by Michael Barnes | Sep 26, 2023 | Product Information

Table of Contents Contact LeBlond for OES S-M Parts The History of Standard Modern & LeBlond Need S-M Components? Key Standard Modern Maintenance Procedure Lubrication on the S-M Series 4000 Lathe Helping You Service Vintage S-M Lathes KEY TAKEAWAYS TL;DR In...

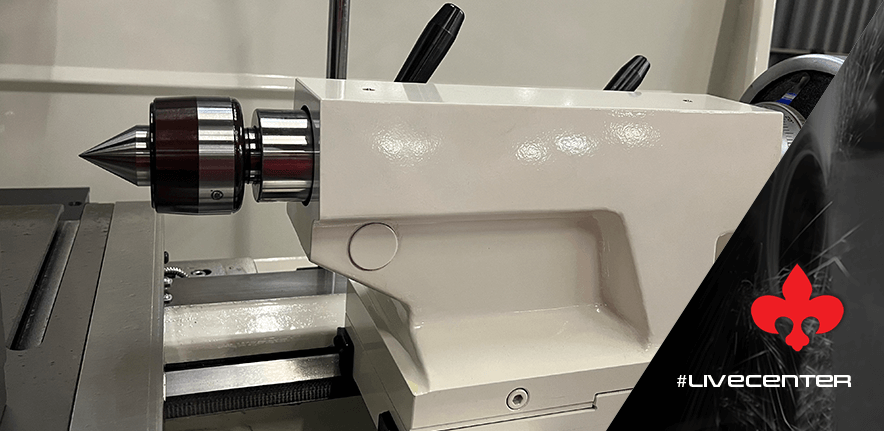

by Michael Barnes | Sep 18, 2023 | Product Information

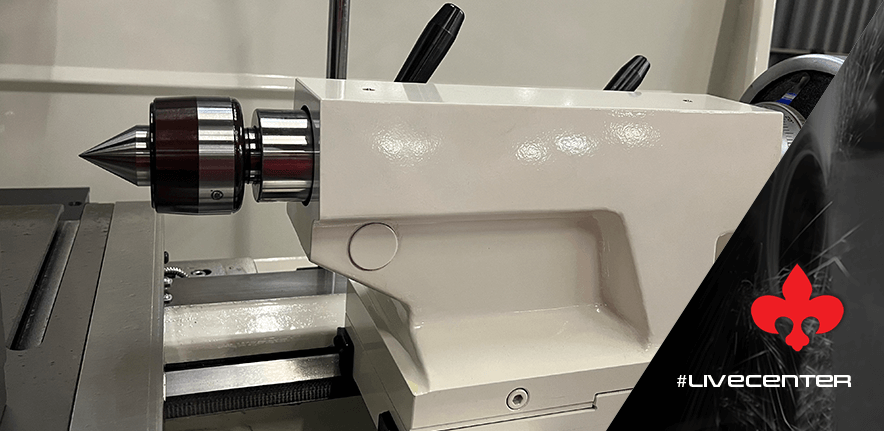

Table of Contents Live vs. Dead Centers Types of Live Centers & Their Applications Understanding the Taper Choosing the Right Features Selecting the Right Live Center Contact LeBlond for Live Center Pricing TL;DR A live center is a machine tool accessory...

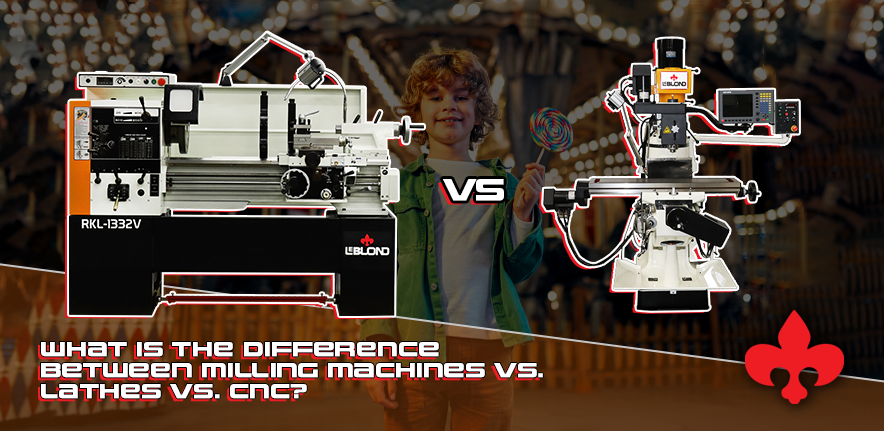

by Michael Barnes | Aug 2, 2023 | Product Information

Table of Contents Best a Hard-Bitten Carny for Machine Tool Wisdom Milling Machines vs. Lathes Hop on the Ferris Wheel for a Cylindrical Cut Milling Machines Are Like the Shooting Game More on Milling Machines vs. Lathes What Are Milling Machines Used For? What Are...

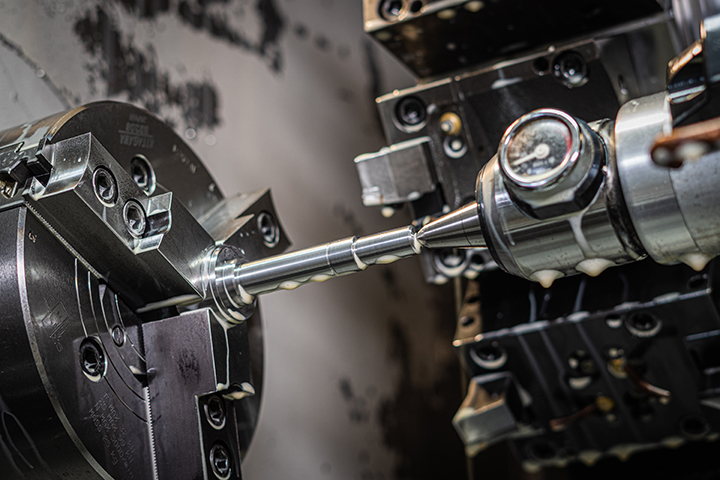

by Michael Barnes | Jul 18, 2023 | Product Information

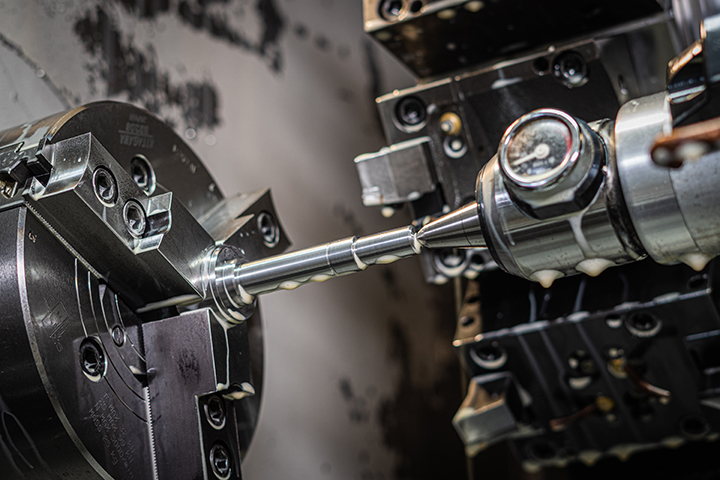

Lathes have become a crucial tool in any production scenario that calls for a holding and rotating dynamic. The machine is also useful in the cutting, polishing and turning of workpieces. Unlike the milling machine, a lathe is designed to rotate the working part with...

by Michael Barnes | Aug 23, 2023 | News

Table of Contents Request for Quote for Manufacturing Parts How Does Our New Industrial Components Tool Work? What Are You Waiting For? Our Machine Components Are OES. Huh!? Need Online Quoting for Machines? We Have You Covered! Get Parts & Reduce Costs with a...

by Scott Hasson | Aug 27, 2023 | News, Product Information, Tips, Uncategorized

Become a Super Star with These 6 Lathe Tips Below are the secrets to efficient machining Producing parts in manufacturing industry can be challenging without knowing the best techniques to deliver high-quality finished pieces. Many times, leaving out a simple step can...

by Michael Barnes | May 30, 2020 | Product Information

Table Of Contents The Health & Financial Benefits of Using a Lathe for Education What are the Specific Features of the LeBlond RKL-1332? Other Common Educational Lathe Features The Importance of Having a Safe Operation Process What Do Many Spindle Options Mean?...

by Michael Barnes | Jul 2, 2013 | Company Profile

Table Of Contents What is LeBlond Exactly and How Can They Help Me with My Lathe Issues? Our Library is Perfect to Find More Details About Your Old LeBlond Lathe The Regal Lathe: An Example of an Early LeBlond Lathe Where Can You Find Your LeBlond’s Lathe Serial...

by Scott Hasson | Jul 7, 2023 | News, Product Information, Tips, Uncategorized

When Ganging Up is a Good Thing Ganging Up Improves Efficiencies for Metalworking Projects Upon hearing the phase “gang up”, is your initial thought about combining similar machining projects together to drive efficiency? Then, you must be a machine operator. ...