Lathes have become a crucial tool in any production scenario that calls for a holding and rotating dynamic. The machine is also useful in the cutting, polishing and turning of workpieces.

Unlike the milling machine, a lathe is designed to rotate the working part with a tooling bit. The workpiece is rotated on a fixed tooling piece like a drill bit.

Lathes have many components — a headstock, bed, carriage and tailstock.

And the headstock? What does it do and consist of?

A headstock consists of a variety of components like the lever, gear, bearing and a shaft or head unit.

The purpose of this post is to describe the headstock component in more detail for novice machinists, students and anyone looking to broaden their knowledge of an incredibly useful machine tool dating back at least nine centuries.

What Is the Purpose of the Lathe Headstock?

The headstock has the principal use of, like a violin, containing the tuning pegs and other mechanisms that hold the string (or spindle) at its top — similar in appearance to pegboxes. In the tail of the instrument, strings are typically held through tailpieces or bridges, what we think of as the lathe tailstock.

What Is the Purpose of a Headstock Spindle on a Lathe?

Using the above analogy, the headstock spindle is the violin strings. The rotation component of the lathe machine is connected via a headstock to the axle.

The spindle acts as a bridge connecting the rotation of the axle to the working piece as well as to the tail. The spindle has rotational power that allows unique cutting operations to the workpiece, either manually by a machinist or via computer numerical control.

Components of a Lathe Headstock

- Headstock: contains the spindle, gears, shafts, bearings, and machine controls

- Spindle: contains the rotating element for the “violin strings”

- Spindle nose: is the attachment point for a variety of workholding mechanisms

- Chuck: holds workpieces on the lathe such as a three-jaw scroll chuck

- Spindle Speed Control: adjusts spindle speeds by combining gear ratios or through electrically controlled devices like constant surface speed (CSS) through a Digital Readout (DRO) or by electrical motors

Where Do I Find Details About LeBlond Lathe Headstocks?

Right here. On this very website!

You can find headstock details under the “Specification” tab on any of our lathe models.

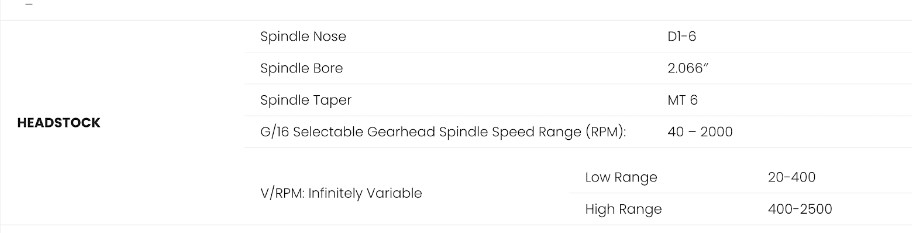

For example, for one of our most popular models, the LeBlond RKL-1332 educational model:

To Detail the Above Specifications

- Spindle Nose: covered above

- Spindle Bore: it is the maximum size piece of stock that you can feed through the headstock

- Spindle Taper: the area inside of the spindle that needs to be clean, undamaged and aligned correctly for optimum cutting accuracy and satisfactory workpiece surface finish

The next two metrics refer to spindle speed control of RPMs and delineate the difference between a gearhead or variable speed spindle.

Maestro the Machine

If you want virtuoso command over many lathes, you must master the headstock that serves as both the lathe brain and hands to control and steady the instrument strings or spindle and chucks that hold workpieces.

You can get minute details on LeBlond lathe headstocks by viewing our machines HERE or calling one of our knowledgeable Sales Engineers at +1(888) 532-5663 (Dial Option 2 Monday – Friday 8am -5pm Eastern) for questions that our site does not answer.

We look forward to hearing from you!