Table of Contents

- Best a Hard-Bitten Carny for Machine Tool Wisdom

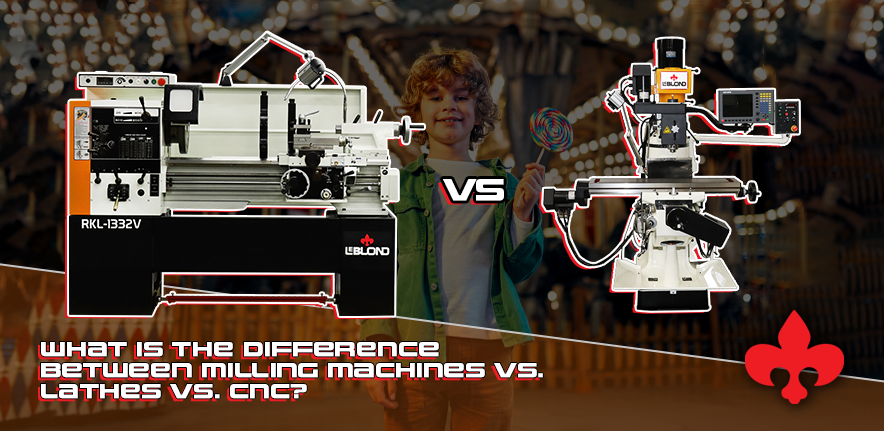

- Milling Machines vs. Lathes

- Hop on the Ferris Wheel for a Cylindrical Cut

- Milling Machines Are Like the Shooting Game

- More on Milling Machines vs. Lathes

- What Are Milling Machines Used For?

- What Are the Main Types of Milling Machines?

- What Are Knee Mills?

- CNC Milling Machines & Lathes

- Our Recommendation: LeBlond LVM 9″ x 48″ Mill with CNC Control

- You Can Take the Machinist Out of the Shop But You Can’t Take the Carnival Out of the Machinist

TL;DR

LeBlond LTD is a Cincinnati-based machine tool supplier aiming to help you with your production machine’s needs. In this post, we’re aiming to help you understand the difference between milling machines, lathes, and CNC machines with a fun and easy-to-follow analogy.

Need to know the differences between milling machines, lathes, and CNC machines?

Then you need to visit the carnival!

Best a Hard-Bitten Carny for Machine Tool Wisdom

Picture a carnival’s vibrant and bustling atmosphere, filled with various attractions and rides that tickle your fancy on a hot spring or summer day.

Milling Machines vs. Lathes

If you were to compare the operation of milling machines and lathes to two popular carnival attractions — the Ferris wheel and the shooting game — you’d get a clearer understanding of their distinct functions.

Hop on the Ferris Wheel for a Cylindrical Cut

Riding a Ferris wheel is a memorable experience with the entire wheel and its passengers rotating in a circular motion around a central axis, similar to how a workpiece rotates around a stationary cutting tool on a lathe.

The lathe’s cutting tool stays fixed in one position while the workpiece is spun, allowing the tool to shape the material.

Milling Machines Are Like the Shooting Game

Imagine facing off against a carny operating the shooting game. He’s seen some things and has lifted a small fortune from little kids, working this hustle.

You’re stationary, aiming your plastic rifle at moving targets to win the ultimate prize — a gigantic stuffed animal for Susie.

This scenario is reminiscent of the milling machine where the workpiece stays stationary while the cutting tool moves around, removing material to achieve the desired shape.

More on Milling Machines vs. Lathes

Milling machines and lathes are both essential machine tools used for shaping various materials.

As illustrated by our carnival analogy, they differ in their operation and applications. In a lathe, the workpiece rotates against a stationary cutting tool, which is guided along the rotating workpiece to remove material and create the desired shape.

Conversely, a milling machine features a rotating cutting tool that moves along the stationary workpiece to remove material.

What Are Milling Machines Used For?

Milling machines are versatile tools used to cut, shape and sculpt materials such as wood, metal, and plastic. They employ a variety of cutting tools, including spinning blades, drills, and abrasives, to achieve the desired result.

High-quality milling machines, like the vertical mill line offered by LeBlond, feature cast iron construction, adjustable speed motors, and power feeds that move the X and Y axes. These machines are ideal for applications in metalworking and various other industries.

What Are the Main Types of Milling Machines?

Mills can be broadly classified into vertical and horizontal milling machines based on the orientation of the cutting tool.

Vertical milling machines have a vertically oriented spindle while horizontal milling machines feature a horizontally oriented spindle.

Some machine tools, like a universal milling machine, combine elements of both vertical and horizontal milling machines for greater versatility.

What Are Knee Mills?

A knee mill, also known as a turret mill, is a versatile machine commonly found in smaller workshops and industrial machine shops.

These machines are smaller and more affordable than other milling machines, making them ideal for complex and simple applications. LeBlond offers its own line of manual milling machines for hobbyists and industrial shop floors.

CNC Milling Machines & Lathes

Do carnivals offer the opportunity to best Mr. Roboto in a game of virtual reality chess? If not now, maybe in the future…?

The carny directing this game would be at a different pay grade than the shooting game or Ferris wheel operator.

This computer-driven carnival game is analogous to CNC machinery.

CNC, or Computer Numerical Control, is a technology that uses computer-controlled systems to operate machine tools with enhanced precision, speed, and efficiency.

CNC machines are ideal for machine shops and schools looking to improve productivity and quality.

CNC milling machines and lathes are similar in their basic functionality, but CNC lathes are primarily used for turning operations while CNC mills are designed for cutting and shaping milling operations.

Our Recommendation: LeBlond LVM 9″ x 48″ Mill with CNC Control

LeBlond offers a top-of-the-line CNC mill, the LVM 9″ x 48″, with advanced CNC control for seamless operation and improved productivity.

This machine boasts a powerful motor, rigid construction, and user-friendly controls that make it ideal for various milling applications.

The LVM 9″ x 48″ CNC best milling machine offers numerous benefits, including increased precision, reduced setup time and enhanced repeatability in the milling process, making it a valuable addition to any machine shop or educational institution.

You Can Take the Machinist Out of the Shop But You Can’t Take the Carnival Out of the Machinist

Flowers are blooming and the days are growing longer and hotter.

It’s getting about time to visit the carnival or summer fair, buy some funnel cake and hop on a ride.

While you ride the Ferris wheel and face a hard-scrabble carny in the shooting or computer-operated game, you’ll be experiencing firsthand the differences between manual mills like vertical mills, lathes, and CNC equipment.

If you have additional questions on these machines or would like pricing information, call LeBlond at +1(888) 532-5663 and dial Option 2 (Monday through Friday 8am – 5pm Eastern).

We look forward to hearing from you!

💡KEY TAKEAWAYS

- The lathe’s cutting tool stays fixed in one position while the workpiece is spun, allowing the tool to shape the material.

- Milling machines and lathes are both essential machine tools used for shaping various materials.

- CNC machines are ideal for machine shops and schools looking to improve productivity and quality.