Table of Contents

- What is a Vertical Milling Machine?

- Horizontal vs. Vertical Milling Machines

- Reason #1: Faster Feeds & Speeds

- Reason #2: Enhanced Precision & Accuracy

- Reason #3: Multiple-Axis Capability

- Overview of LeBlond Vertical Mills

- Contact LeBlond for Vertical Mill Pricing

- KEY TAKEAWAYS

TL;DR

LeBlond offers a wide variety of vertical mills — versatile tools used in machining operations such as milling, drilling, boring, and tapping. In this blog post, we explain the three main ways vertical mills improve a machinist’s productivity. You’ll learn what makes these machine tools indispensable for intricate tasks that require versatility, precision, and efficiency.

Need to power up your vertical mill further? For a limited time, LeBlond is offering a 25% off sale on Newall DROs to boost your mill productivity. Call a LeBlond Sales Engineer at 888-532-5663 and select Option 2.

Before explaining why vertical mills are superior machines to boost productivity in your shop, let’s get the basics out of the way.

What is a Vertical Milling Machine?

Vertical mills are commonly used in machine shops and manufacturing facilities to create precision parts, shape metal components, and produce intricate cuts and designs.

The choice between mills depends on the specific requirements of the machining project and the size and weight of the workpieces to be processed.

Here’s a breakdown of its key components and functions:

- Vertical Orientation

- Cutting Tool

- Drawbar

- Quill

- Worktable

That said, you might wonder what is the difference between vertical and horizontal mills.

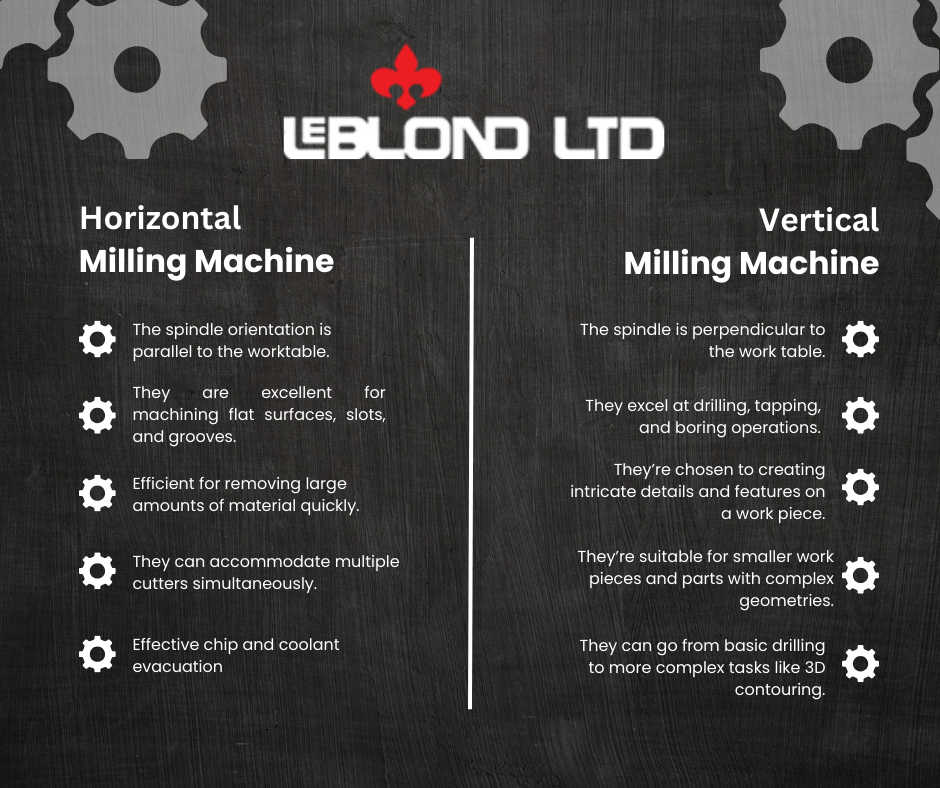

Horizontal vs. Vertical Milling Machines

Horizontal mills are typically favored for heavy material removal and face milling while vertical mills are preferred for precise drilling, tapping, and tasks that require high accuracy.

Many machine shops use both types of milling machines to cover a broad spectrum of machining needs.

Here’s a comparison of horizontal and vertical milling machines:

If you are interested in a vertical mill, don’t miss our 25% off sale on a Newall DRO for a limited time.

A Digital Readout can significantly enhance the capabilities of a vertical mill, improve precision, save time, and streamline the machining process.

For more information, call a LeBlond Sales Engineer at 888-532-5663 and select Option 2.

Let’s now get into the three main reasons why you need a vertical mill to increase your shop’s productivity.

Reason #1: Faster Feeds & Speeds

Vertical milling machines can save time and increase machining efficiency in various ways.

First, the spindle moves directly up and down along the Z-axis. This direct movement enables rapid positioning and precise depth control, especially beneficial for drilling, tapping, and other operations that require vertical accuracy.

Operators can quickly adjust the spindle’s position, reducing the time spent on setup and tool changes.

Vertical mills often have high spindle speed capabilities that allow for faster cutting speeds.

Higher spindle speeds enable the cutting tool to remove material more rapidly, resulting in reduced machining time for a given task.

These machines are typically more rigid and stable than horizontal mills, particularly for tasks requiring vertical cuts. This increased rigidity allows for higher cutting forces and more aggressive feeds and speeds without compromising precision.

Faster material removal is achieved while maintaining dimensional accuracy.

Reason #2: Enhanced Precision & Accuracy

Vertical mills are typically designed with robust and rigid structures that minimize vibrations and flexing during machining operations.

This rigidity ensures that the cutting tool maintains a stable position relative to the workpiece, resulting in accurate cuts.

Precise spindles on a vertical knee mill are capable of maintaining accurate rotational speeds and minimal runout.

The vertical orientation of the spindle allows for precise and direct movement along the Z-axis (vertical axis). This is especially advantageous for drilling, tapping, and boring operations where accurate vertical positioning is essential.

Vertical milling machines provide excellent depth control due to the straightforward Z-axis movement, allowing the machinists to achieve precise and consistent depths when milling or drilling into a workpiece.

Vertical mills often use collets, chucks, or tool holders that securely hold cutting tools in place. This minimizes tool runout and ensures that the tool remains precisely aligned with the spindle axis.

Additionally, automatic tool changers (ATCs) in some vertical mills allow for quick and accurate tool changes.

Overall, many modern mills are equipped with computer numerical control (CNC) systems.

CNC technology enables the creation of highly precise tool paths, accurate tool engagement, and precise positioning of the workpiece. CNC systems can also compensate for any deviations, leading to enhanced accuracy.

Reason #3: Multiple-Axis Capability

The additional axes on a vertical knee mill provide greater freedom of movement and precise control, making vertical mills suitable for tasks that demand intricate geometries and advanced machining techniques.

The fundamental axis configuration of a vertical milling machine includes three primary axes:

- X-Axis: Horizontal movement of the worktable (left and right).

- Y-Axis: Forward & Backward movement of the worktable (in and out).

- Z-Axis: Vertical movement of the spindle (up and down).

Fourth Axis (Rotary Axis)

Many vertical mills can be equipped with a fourth axis, often referred to as a rotary axis or A-axis. This axis allows the workpiece to rotate or index during machining. It is particularly valuable for tasks involving cylindrical or symmetrical workpieces. The fourth axis enables other features like engraving, gear cutting, and helical milling.

Fifth Axis

Some advanced vertical milling machines may feature a fifth axis, typically known as the B-axis. The fifth axis allows the spindle or worktable to tilt or swivel, enabling multi-axis machining from various angles. This capability is useful for complex contouring, 3D machining and producing parts with undercuts.

Sixth Axis (Optional)

In certain specialized applications, a sixth axis, known as the C-axis, can be added. The C-axis rotation complements the other axes and facilitates intricate machining, such as sculpting or cutting complex surfaces.

CAD/CAM Integration

To fully leverage the multi-axis capabilities of vertical mills, manufacturers often use computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These programs allow engineers and machinists to create and simulate complex tool paths, ensuring efficient and accurate machining.

In summary, the multiple-axis capabilities of vertical milling machines significantly expand their range of applications and allow for the efficient production of complex and highly precise parts.

These capabilities are particularly valuable in industries where intricate geometries, 3D contours and fine details are essential.

Overview of LeBlond Vertical Mills

LeBlond offers a comprehensive range of vertical mills, catering to both CNC and manual milling requirements.

Among our popular offers, is the LeBlond 9” x 48” CNC mill, equipped with 3-axis control and a convenient remote stop/go switch.

In comparing CNC to manual milling, the advantages are clear.

The CNC milling machine, featuring a robust 1.4 GHz processor and 1.25 MB of user memory, stands out for its exceptional precision, uniformity and efficiency.

LeBlond’s CNC mill enables precision to cut down to minute fractions of a millimeter, ensures consistent machining to exact specifications, reduces reliance on manual labor, enhances productivity through extended operational periods, and offers unmatched flexibility in tackling intricate geometries that might challenge a manual mill.

Overall, vertical milling machines like these are indispensable tools in machining, improving productivity, and facilitating efficient, high-quality part production.

Contact LeBlond for Vertical Mill Pricing

Speaking of productivity, a Digital Readout can be a huge asset to a vertical mill.

Don’t miss LeBlond’s 25% off Newall DRO sale for a limited time.

Call a LeBlond Sales Engineer at 888-532-5663 and dial Option 2 for more information.

If you are interested in pricing for a LeBlond vertical mill, please get in touch:

- Please leave a comment, and we’ll be happy to help.

- Call us or check out THIS PAGE describing all our mill products.

We look forward to hearing from you!

💡 KEY TAKEAWAYS

- Vertical Mills are highly versatile and can perform a wide range of machining tasks, including milling, drilling, boring, and tapping.

- Horizontal mills are typically favored for heavy material removal and face milling while vertical mills are preferred for tasks requiring high accuracy.

- Multiple-axis capability, enhanced precision and faster speeds are the three main ways vertical mills can increase a machinist’s productivity.