Table of Contents

- Live vs. Dead Centers

- Types of Live Centers & Their Applications

- Understanding the Taper

- Choosing the Right Features

- Selecting the Right Live Center

- Contact LeBlond for Live Center Pricing

TL;DR

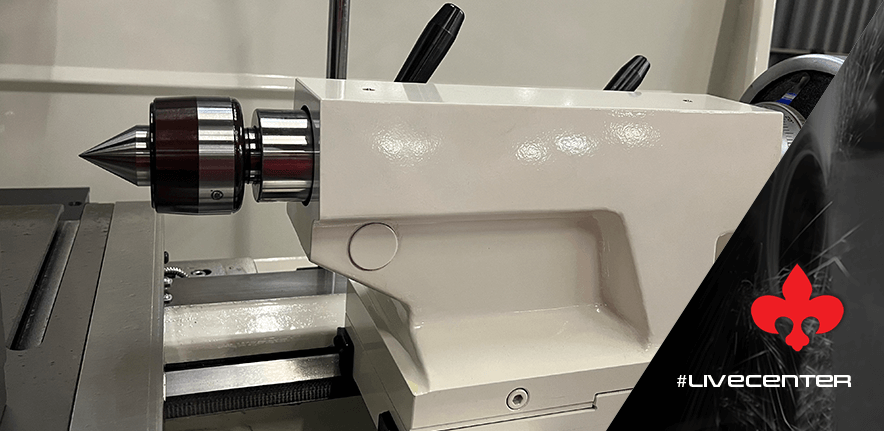

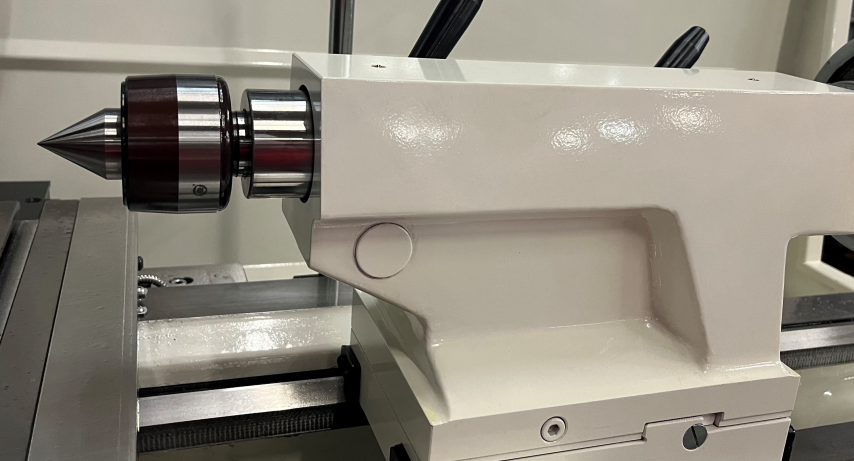

A live center is a machine tool accessory used on a lathe to support longer or heavier workpieces more securely, preventing unwanted friction and wobbling. In this post, we go into detail on live centers and utilizing them on a vintage or RKL LeBlond for more precise machining.

Imagine…

…you are a machinist working high-precision manufacturing setup that supplies the aerospace industry.

You are tasked with creating a complex component, featuring a long, slender profile.

It requires support at multiple points to maintain rigidity during the machining process.

You know you need support. You’ve got your steady rests. Now you opt for a live center from a manufacturer like Bison or Royal.

One that is mounted on the tailstock of the lathe and incorporates bearings to allow it to rotate along with the workpiece.

This setup provides the necessary support to the elongated workpiece but also minimizes friction, ensuring a smooth rotation and preventing any deflection or bending that could occur with a stationary support.

By utilizing a live center, you can maintain the critical tolerances required for the aerospace component, ensuring an even, consistent cut along the entire length of the workpiece while preserving the integrity of the finely machined surfaces.

The end product is a machined component that meets stringent industry standards.

Live vs. Dead Centers

A dead center is a type of lathe accessory that supports the end of a workpiece without rotation, providing stability during machining but potentially creating friction and requiring lubrication to prevent wear and overheating.

While live centers revolve with the workpiece, facilitating higher RPMs and less friction, dead centers are stationary, offering a static point of contact with the work material.

With a live center, the direction of the rotation aligns with that of the workpiece, creating a synchronous operation that avoids unnecessary friction and facilitates a smoother process.

Types of Live Centers & Their Applications

Diving deeper, we discover that live centers are not one-size-fits-all.

They come in a variety of configurations each designed to serve a unique purpose:

- Standard Live Centers: Ideal for routine tasks, they offer a balance between performance and budget.

- Heavy Duty Live Centers: Designed to support large loads, their build is sturdier, with variations even within this category such as 4MT and 5MT that indicate the Morse taper and the weight they can handle.

- Bull Nose Live Centers: Crafted for large bore and heavier workpieces, they are an excellent choice when working with materials like hydraulic cylinders or thick wall pipes. Their defining feature is a flat point head.

- Pipe Head Live Centers: Similar to bull nose but with a pointed head, providing a broader surface for mounting, they are designed for turning pipes and tubes.

Understanding the Taper

Understanding the Morse taper (MT) your lathe supports is pivotal in selecting the correct live center.

Matching the live center to the quill of your tailstock ensures you are harnessing the maximum potential of your machinery.

Morse taper is a standardized system used in machining to securely and accurately fit spindle noses and tooling shafts together, utilizing a self-holding taper that facilitates easy installation and removal of tools while maintaining precise alignment and concentricity.

MTs ensure that tools and work holding devices are aligned accurately with the machine’s spindle or tailstock.

You want to focus on your lathe to determine which MT you’ll use; i.e. MT3, MT4 or MT5.

Choosing the Right Features

The selection doesn’t just stop with identifying the type of live center you need.

Live center features play a significant role too.

Options include:

- Carbon Tips: These are crucial in scenarios where wear and tear are major concerns. Carbon tips are hardy, offering resistance to wear, thereby increasing the lifespan of the live center.

- Changeable or Replaceable Centers: Offering flexibility, these centers allow you to switch to components like carbon tips, adapting to the specific needs of the work at hand.

- Super Accurate Centers: If precision is your priority, opting for live centers with high Total Indicator Runout (TIR) would be beneficial. TIR is a popular metric in machining, indicating the precision and quality of a product.

Selecting the Right Live Center

As you venture into selecting the perfect live center, taking into consideration the specific needs of your project, your lathe capabilities, and the features of the live center can lead you to make an informed choice.

Here are five easy steps to choose your live center:

- Select the right Morse taper

Check the MT on your tailstock quill.

- Consider your workpiece weight

Knowing this weight is crucial because it represents the maximum load that a live center can safely support. Adhere to this specified weight limit to avoid damage.

- Determine your thrust load

This will ensure that the lathe securely holds the workpiece in place in the center.

- Check the point style

It’s important to select the appropriate point style to ensure proper support, minimal deflection, and the desired surface finish. Keep in mind that standard point live centers are best when rigidity and weight requirements are used.

- Measure your operating speed

Determine the required operating speed to avoid further damage to your lathe or workpiece.

Contact LeBlond for Live Center Pricing

Live centers are a critical steadying and “pinning” function for a lathe.

LeBlond is a one-stop shop for machines and the needed accessories to fulfill all job requirements in your machine shop or classroom.

If you are purchasing a new RKL LeBlond lathe or outfitting one of our vintage machines, get in touch to discuss pricing:

- If you have any questions on live centers, please comment; we’ll be happy to help.

- Prefer a phone call? Reach out to us at (888) 532-5663 and select Option 2.

We look forward to hearing from you!

💡 KEY TAKEAWAYS

- Live centers are vital for supporting heavy workpieces and preventing errors on a lathe.

- While live centers revolve with the workpiece, facilitating higher RPMs and less friction, dead centers are stationary, offering a static point of contact with the work material.

- Live centers come in a variety of configurations designed to serve a unique purpose.