Become a Super Star with These 6 Lathe Tips

Below are the secrets to efficient machining

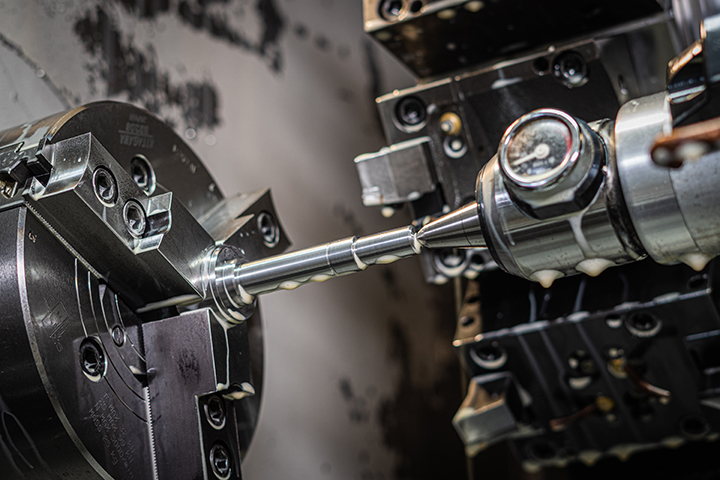

Producing parts in manufacturing industry can be challenging without knowing the best techniques to deliver high-quality finished pieces. Many times, leaving out a simple step can diminish the end-result causing re-work or scrap. The following tips when put into practice will greatly improve the final output on finished parts.

1. Minimize Dwell Time

Don’t allow the tooling to spend too much time cutting in one location on the workpiece. This minimizes tool wear and heat buildup.

2. Fixture and Workholding Design

Design and utilize fixtures and workholding systems that can securely hold multiple parts simultaneously. Consider custom jigs, collets, chucks, or fixtures with multiple clamping positions to accommodate the batched parts. Well-designed workholding solutions ensure stability and accuracy during machining, enabling efficient processing of multiple parts.

3. Use proper chip control

Use appropriate chip breakers, correct tool geometry and adjust cutting parameters to prevent chip entanglement, reduce tool wear and improve surface finish.

4. Practice interrupted cutting techniques

Materials like brass or aluminum can create long chips, also known as birdnests, which can foul up the machine and efficient cutting. Machining must be paused to remove the birdnest. Use the following interrupted cutting techniques:

- Adding chip breaker inserts

- Varying feed rates

- Controlling depth of cuts

- Using interrupted cuts (if appropriate)

- Using wiper inserts (best for finishing cuts)

- Adjusting cutting speeds

- Applying lubrication and coolant

5. Optimize tool approach and exit

When starting, approach the workpiece slowly to avoid sudden shocks that cause chatter or deflection. Similarly, slow exits prevent tool marks or damage to the workpiece.

6. Keep your lathe bearings and filters clean

This simple act of maintenance will extend the life of the lathe and improve the quality of parts output. Use a magnet to collect metal chips, dust, debris and settlement out of the bearing races. Keeping the mechanical pieces uncontaminated reduces chatter and damage. Additionally, filters need to be changed as frequently as 6 months to one year depending on the level of use. Lathe filters keep the machine free and clear of particulate, just like the filters in a car.

There are some universal strategies when working on a lathe to get the best parts from the run. Integrating one or a few of the techniques listed above will help produce more consistent parts. Contact your LeBlond representative for more details on improving quality or submit your question directly by submitting a request through our online form or call (888) 532-5663 and select option 2.