Table Of Contents

- The Health & Financial Benefits of Using a Lathe for Education

- What are the Specific Features of the LeBlond RKL-1332?

- Other Common Educational Lathe Features

- The Importance of Having a Safe Operation Process

- What Do Many Spindle Options Mean?

- Common Topics Discussed When Learning About Educational Lathes

- Is The Educational Lathe Used for Teaching Only?

- Need Pricing on the RKL-1332? Contact LeBlond

- Frequently Asked Questions

TL; DR

LeBlond LTD provides an educational lathe for high school and post-secondary institutions. In this post, we examine the RKL-1332 Series lathe for education in detail, including a summary of machine features and benefits. We’ll also review why LeBlond’s educational lathe is built to help students learn the finer points of machining.

The Health & Financial Benefits of Using a Lathe for Education

Are you on the path to being a master machinist?

Are you instructing these young Jedis and need a compact but powerful lathe to teach on?

Meet the RKL-1332, LeBlond’s lathe for education.

Before we dive into the machine’s features, what are the benefits of using a manual lathe for high schools, community colleges, and universities?

Stay Healthy Young Jedi

Besides developing talent and problem-solving skills, you’ll be safe from accidents while learning on LeBlond’s RKL-1332 Series educational lathe.

This model is a more specialized machine. We’ll cover the safety features in more detail later in the post.

Earn That Bag, Young Machinist

The second most important subject is the financial benefit.

Time is money for all industries.

A skilled machinist will cut time, increase production and reduce costs after becoming proficient on a high-capacity machine like the RKL-1332.

You won’t have to worry about wasting materials or time. Learning lathe operations or metalworking techniques can equip operators with machining skills and related fields like tool making and fitting.

Now, let’s get to the real deal!

What Are the Specific Features of the LeBlond RKL-1332?

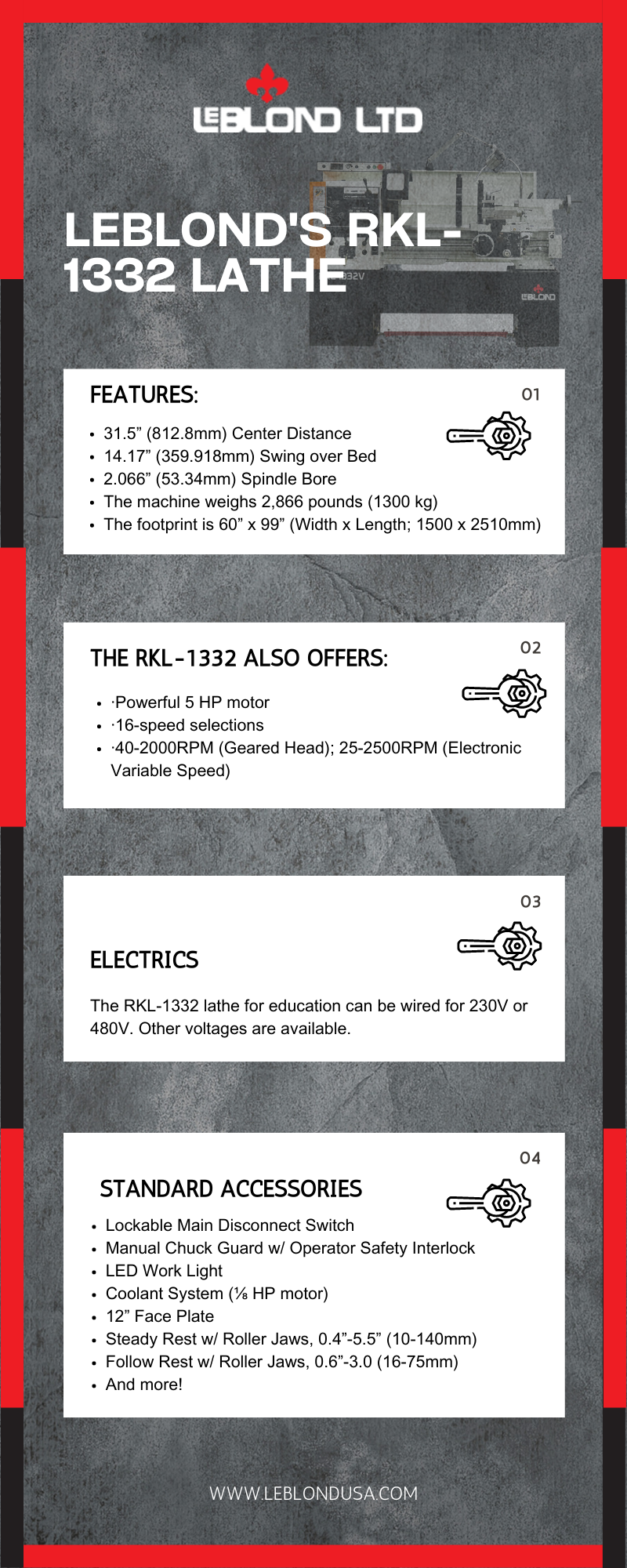

Our RKL-1332 lathe for education features:

- 31.5” (812.8mm) Center Distance

- 14.17” (359.918mm) Swing over Bed

- 2.066” (53.34mm) Spindle Bore

The center distance is the distance between the two centers of the lathe, namely the headstock center and the tailstock center. The headstock center is located at the spindle end of the lathe while the tailstock center is positioned at the opposite end of the lathe bed.

The swing-over bed refers to the largest diameter workpiece that can be turned on the lathe without interfering with the bed.

The spindle bore is the diameter of the hole or opening in the spindle of the lathe. It represents the maximum diameter of the workpiece that can pass through the spindle and be held securely for machining.

Petite But Powerful

The RKL-1332 lathe for education has monster power but not a monster footprint:

- The machine weighs 2,866 pounds (1300 kg)

- The footprint is 60” x 99” (Width x Length; 1500 x 2510mm)

The RKL-1332 also offers:

- Powerful 5 HP motor

- 16-speed selections

- 40-2000 RPM (Geared Head); 25-2500 RPM (Electronic Variable Speed)

The gearhead spindle system allows for a wide range of spindle speeds that is essential for accommodating different workpiece materials and machining operations.

Electronic variable speed refers to a spindle driven by an electric motor controlled by an electronic speed controller. The speed controller allows the operator to adjust the spindle speed continuously within a certain range, typically by using a control panel or interface like a digital readout (DRO).

Our educational lathe possesses the merits of a full-sized lathe with the budget-conscious price tag and small footprint of a machine that will fit a classroom, a small machine shop, or a hobbyist’s garage.

LeBlond Lathe for Education Summary

Check out this snapshot of our lathe for education:

Other Common Educational Lathe Features

Educational lathes have several features that make them suitable for learning purposes:

Safety Features

Educational lathes often come equipped with safety features such as emergency stop buttons, protective guards, footbrake, and interlocks that prevent accidental operation.

Variable Speed Controls (EVS Model)

To allow users to adjust the rotation speed of the lathe. Lower speeds are suitable for larger pieces or delicate materials while higher speeds are used for smaller or more intricate work.

Digital Readout (DRO)

Advanced educational lathes may come equipped with a digital readout system that displays travels of the X & Z-Axis. This feature enhances precision and consistency in turning operations.

User-Friendly Controls

Clear labeling, intuitive interfaces, and ergonomic design make it easier for students to learn and use the lathe effectively.

What Do Many Spindle Options Mean?

The RKL-1332 machine is offered as a Gearhead or Electronic Variable Speed as mentioned previously.

The statement “spindle options” refers to the availability of different types of spindles that can be used with educational lathes.

The spindle is a crucial component of a lathe that holds and rotates the workpiece being turned.

Having multiple spindle options in educational lathes enhances the versatility and capabilities of the lathe. It allows students and users to work on a wide range of turning projects, accommodating different sizes of workpieces and enabling the use of specialized accessories or techniques.

This flexibility promotes learning and exploration. Users can adapt the lathe to suit their specific needs and gain experience in various aspects of lathe operations.

The Importance of Having a Safe Operation Process

Prioritizing safe operation processes with lathes is essential for personal safety, accident prevention, hazard mitigation, and more.

By establishing and following proper safety protocols, operators can create a secure and productive environment while using lathes for educational or professional purposes.

Here are three key reasons highlighting the importance of a safe operation process with lathes:

- It reduces the risk of equipment failure and unexpected incidents.

- Operators commit to future endeavors and ensure safety in machining environments.

- You avoid regulatory penalties by adhering to safety regulations and guidelines

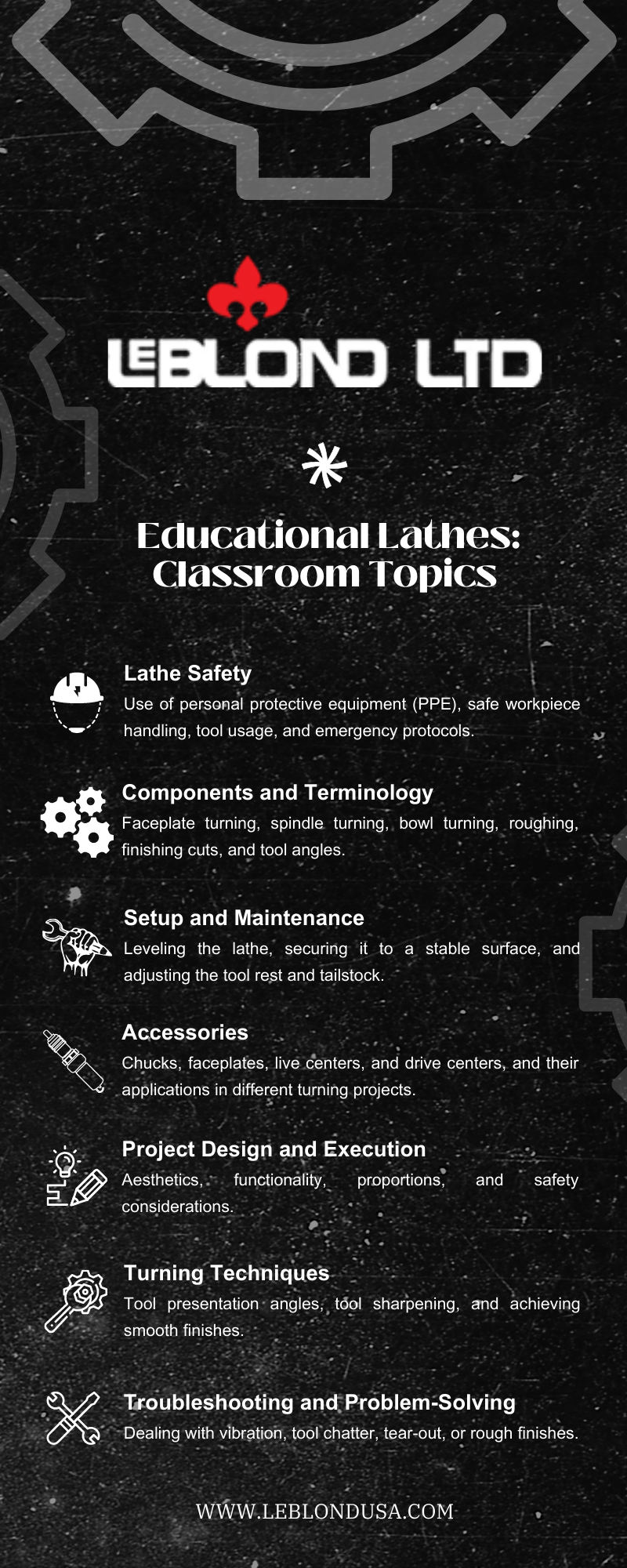

Common Topics Discussed When Learning About Educational Lathes

Working with lathes requires concentration and skill for efficiency and safety. Adopting best practices and following processes will allow the students to maximize their production time and minimize risks like injuries or damage to their lathes.

If students want to master the lathe, they must go through the following educational topics:

Want to step up your game and become an immortal machinist? Join our show Lessons with LeBlond and become a lathe master. Click/tap HERE for more info.

Is The Educational Lathe Used for Teaching Only?

No, educational lathes are not used solely for teaching purposes. While they are commonly employed in educational settings such as schools or vocational training centers, they can also be used for personal projects, hobbyist pursuits, or professional metalworking activities.

The term “educational” typically indicates that these lathes are suitable for learning and skill development, but they are not limited to an educational context.

The RKL-1332 is ideal for a machine shop or anyone who requires power with a small footprint. For example, the RKL-1332 is an ideal lathe for gunsmithing.

Once students have acquired the necessary skills and experience, educational lathes can also be utilized for a wide range of turning projects such as pens, furniture components, decorative items, or artistic work.

Need Pricing on the RKL-1332? Contact LeBlond

We hope this information has helped you understand what our educational lathe offers.

- If you have any specific questions about the RKL-1332, please leave a comment and we’ll be happy to help.

- If you need an RKL-1332 for your shop, school, or students, click or tap HERE.

- Or call us at (888) 532-5663 and select Option 2.

We look forward to hearing from you!

💡 Key Takeaways

- The RKL-1332 will assist all students in learning the basics of machining by dealing with a more specialized manual lathe.

- Lathe safety, troubleshooting, and problem-solving are common topics taught to students interested in a career as a machinist or related field.

- The RKL-1332 is not just for schools. It is ideal for a machine shop or anyone who requires power with a small footprint.

Frequently Asked Questions

What is a teach lathe?

A “teach lathe” or educational lathe plays a vital role in providing practical skills and knowledge to individuals pursuing careers in machining, manufacturing, and related fields. They serve as foundational tools for developing machining skills, fostering creativity, and preparing students for real-world applications in industries that utilize lathes for various manufacturing processes.

What can a lathe be used for?

A lathe is a versatile machine tool that can be used for various purposes across different industries. Turning, facing, drilling, and tapering are just a few examples of what a lathe can be used for. The specific applications depend on the type of lathe, tooling, and the creativity and skill of the operator.

What can you make with a manual lathe?

The following examples highlight the versatility of a manual lathe, demonstrating its capability to produce a wide range of precision parts and components. The machinist’s skill and expertise play a crucial role in maximizing the lathe’s potential and achieving desired outcomes. An operator may repair and restore components, create decorative items, prototype parts, and much more.

Why should you own a lathe?

If you need precision machining capabilities, customization or seek a career as a machinist, owning a lathe can be a worthwhile investment.

I’d kill for one of these lathes, but no hope.

Just one point

The specifications show

5 inch / 812mm centre distance.

I think that should be more like 32 inch centre distance ?

Cheers, Peter Bready

Hello Peter, thank you for your comment. You are correct. There were errors in the center distance and swing numbers when this post was first published. The post has been corrected. LeBlond apologizes for the initial inaccurate information. We do offer financing for all our machines. You might want to contact a LeBlond Sales Engineer and look into this. All our machines are within reach!

What is the spindle nose configuration, L series or D series?

What is the taper in the head and tailstock?

What range of thread pitch will it cut?

Steve, thanks for your questions. Someone will reach out to you. For immediate service, call 888-532-5663 and dial Option 2.