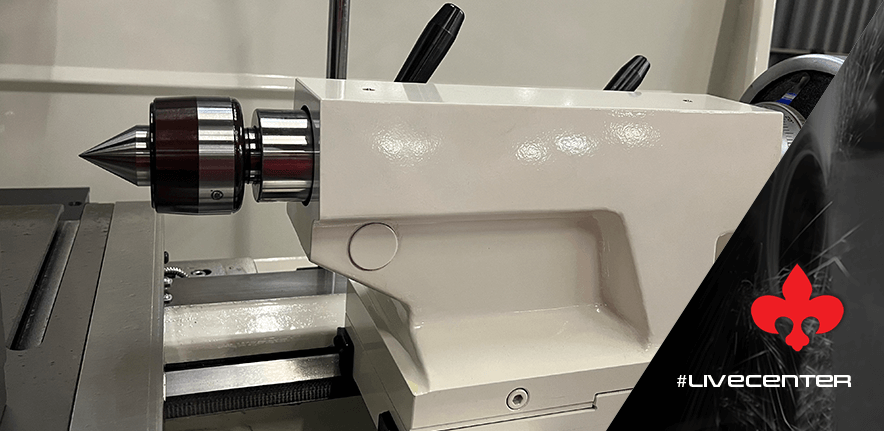

Table of Contents Live vs. Dead Centers Types of Live Centers & Their Applications Understanding the Taper Choosing the Right Features Selecting the Right Live Center Contact LeBlond for Live Center Pricing TL;DR A live center is a machine tool accessory...

Product Information

What Is the Difference Between Milling Machines vs. Lathes vs. CNC?

Table of Contents Best a Hard-Bitten Carny for Machine Tool Wisdom Milling Machines vs. Lathes Hop on the Ferris Wheel for a Cylindrical Cut Milling Machines Are Like the Shooting Game More on Milling Machines vs. Lathes What Are Milling Machines Used For? What Are...

Maestro the Machine: What Is the Headstock on a Lathe?

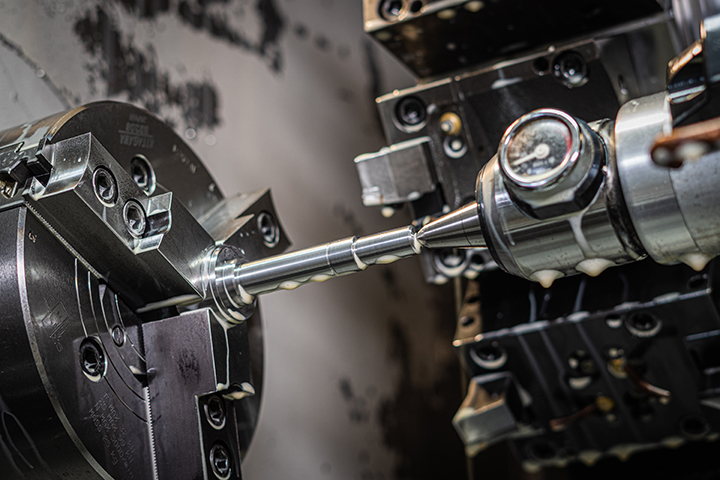

Lathes have become a crucial tool in any production scenario that calls for a holding and rotating dynamic. The machine is also useful in the cutting, polishing and turning of workpieces. Unlike the milling machine, a lathe is designed to rotate the working part with...

Master Six Lathe Tips to Improve Your Output of High-Quality Workpieces

Become a manufacturing super star by following these 6 lathe tips. When put into practice they will greatly improve the final output on finished parts.

Get Hands-On Learning with a Lathe for Education

LeBlond’s RKL-1332 lathe for education is powerful and petite. Check out a summary of this small dog that packs a big bite!

Gang Up Machining Projects for Improved Efficiencies

Implementing batch processing and workpiece consolidation on a lathe involves optimizing your machining processes to efficiently produce multiple parts in a single setup.

Where Do You Find K.O. Lee Parts?

Need affordable OEM K.O. Lee parts? Go with LeBlond, a leader in the machine tool industry.

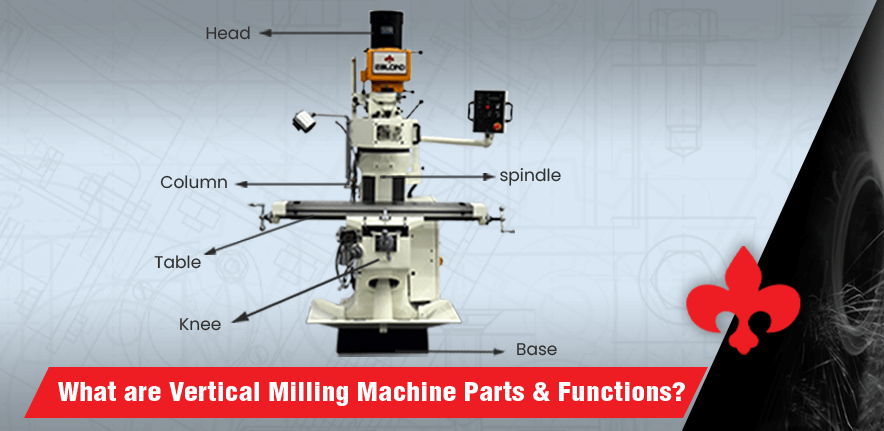

What Are Vertical Milling Machine Parts & Functions?

TABLE OF CONTENTS The Parts of a Vertical Mill Milling Machine Uses LeBlond Mills: Powerful and Precise LeBlond Manual Mills Vertical Mill = Essential Tool Vertical milling machines are a type of industrial machinery that is widely used in the manufacturing...

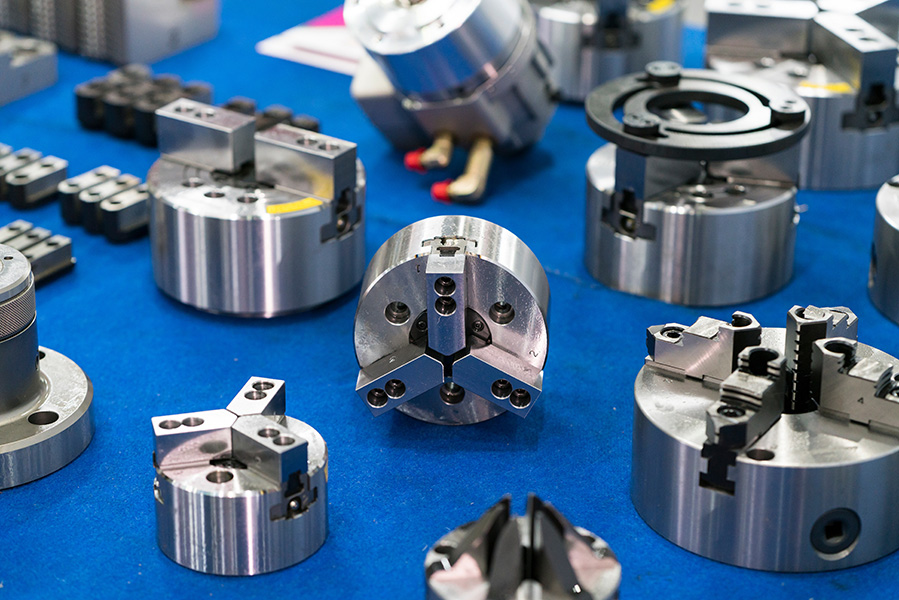

Workholdings are Lathe Workhorses

Workholdings are Lathe Workhorses Accuracy and precision are vital for producing parts with high tolerances in advanced lathe machining. Reliable workholding solutions ensure high-quality and repeatable machining results. Here are five reasons to get workholdings...