- The Parts of a Vertical Mill

- Milling Machine Uses

- LeBlond Mills: Powerful and Precise

- LeBlond Manual Mills

- Vertical Mill = Essential Tool

Vertical milling machines are a type of industrial machinery that is widely used in the manufacturing industry for milling operations.

Milling is a process of removing material from a workpiece by using rotary milling cutters to create a desired shape.

Vertical mills are so named because the cutting head is oriented vertically. These milling machines can be used to perform a wide range of milling operations, including face milling, end milling, and drilling.

In this blog post, we will discuss the various parts and functions of a vertical milling machine.

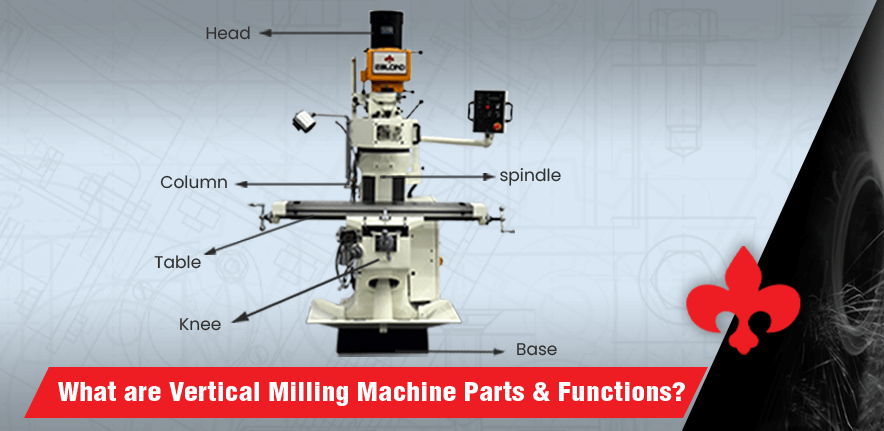

The Parts of a Vertical Mill

Column and Base

The column and base are the primary supporting structures of a milling machine. The column is a vertical beam that is mounted on the base. The base is a heavy casting that is bolted to the floor. The column supports the spindle and the various attachments that are used in a milling operation. The base provides stability to the machine and helps absorb vibrations generated during milling operations.

Knee

The knee is a rigid casting that is mounted on the column. It provides vertical movement to the worktable and supports the saddle. The knee is equipped with a vertical positioning screw that allows it to be raised or lowered. This vertical adjustment is used to set the depth of cut for the milling operation.

Saddle and Swivel Vise

The saddle is a sliding casting that is mounted on the knee of a milling machine. It provides horizontal movement to the worktable. The saddle is equipped with a swivel vise that can be rotated and machined at any angle.

Power Feed Mechanism

The power feed mechanism of a milling machine is used to provide longitudinal, transversal or vertical feed to the worktable. The power feed mechanism is located on the knee and is controlled by a set of levers. The feed rate on the X & Y Axes can be adjusted to suit the material being machined.

Table

The table consists of a rectangular casting that is located on the saddle of a milling machine. The table is equipped with T-slots that allow the workpiece to be clamped directly to the table. The table can be moved longitudinally, transversally or vertically to position the workpiece for milling operations. The work table is also equipped with a variable speed power feed that allows the workpiece to be moved at a constant rate during machining operations.

Overhanging Arm

The overhanging arm is a horizontal casting that is mounted on the column of a horizontal milling machine. The overhanging arm carries the arbor support and the arbor. The arbor is a horizontal shaft that holds the cutting tools. The arbor support is a casting that is mounted on the overhanging arm of a horizontal milling machine and supports the arbor of the milling machine.

Milling Machine Uses

The function of a milling machine is to remove material from a workpiece to create a desired shape. This is achieved by using a rotating milling cutter with multiple teeth that remove the material, as it moves along the surface of the workpiece.

The milling cutter is mounted on a spindle that rotates at high speeds and can be moved in multiple directions to create various shapes and angles.

A milling machine can be used in a wide range of industries and applications from small workshops to large manufacturing plants. Below are some common uses of vertical milling machines.

Precision Machining

Vertical milling machines are commonly used in precision machining applications where accuracy and precision are critical. They are used to create complex parts with tight tolerances and high surface finishes.

Production Machining

Vertical mills are also used in production machining applications where large quantities of parts need to be produced quickly and efficiently. They are capable of performing high-speed machining operations that can reduce cycle times and increase production rates.

Mold and Die Making

Vertical milling machines are often used in mold and die-making applications where complex shapes and contours need to be machined into hardened materials. They are capable of producing intricate details and can be used to create molds and dies for a variety of industries, including automotive, aerospace, and medical.

Tool and Die Making

Vertical milling machines are also used in tool and die-making applications where precision and accuracy are critical. They are used to create cutting tools, jigs, fixtures, and other tooling components that are used in manufacturing processes.

Education

Vertical milling machines are commonly used in educational settings to teach students the principles of machining and manufacturing. They are often used in engineering and manufacturing programs to teach students how to use CNC technology and other advanced machining techniques.

Overall, vertical milling machines are versatile and essential tools in the manufacturing industry. Whether you are a small workshop or a large manufacturing plant, a vertical milling machine can help you produce high-quality parts quickly and efficiently.

LeBlond Mills: Powerful & Precise

LeBlond produces a variety of vertical mills, both CNC and manual.

LeBlond’s 9” x 48” mill with CNC control features 3-axis control and a remote stop/go switch.

CNC vs. Manual Mill

Our Computer Numerical Control milling machine allows you to automate and precisely control the milling process using a 1.4 GHz processor with 1.25 MB of user memory.

This model provides several advantages over a conventional manual mill, including:

Increased Precision

A CNC milling machine allows you to achieve higher levels of accuracy and precision in your milling operations than a manual mill. This is because the machine can be programmed to make very precise cuts and movements, down to fractions of a millimeter or less.

Consistency

With a CNC mill, you can ensure that every part or component is machined to the same specifications, every time. This is particularly useful in mass production where consistency is crucial.

Reduced Labor Costs

A CNC milling machine requires less manual labor than a manual mill, as the machine can run without constant human supervision. This reduces the need for skilled operators and can result in significant cost savings.

Increased Efficiency

A CNC milling machine is capable of running for extended periods of time which can lead to increased productivity and faster turnaround time over manual milling operations.

Flexibility

A CNC milling machine can be programmed to perform a wide range of milling operations, including complex geometries that would be difficult or impossible to achieve with a manual mill. This makes it a versatile tool for a variety of applications.

LeBlond Manual Mills

LeBlond also offers a variety of manual mills that are more cost-effective than our CNC model.

Here is a snapshot of the LVM series:

10” x 54” (254mm x 1371.6mm)

- Electronic Variable Speed: 50-5000

- Mechanical Speed: 60-4200

- 16-Speed Step Pulley: 80-2760

- Electronic Variable Speed: 50-5000

- Mechanical Speed: 60-4200

- Electronic Variable Speed: 50-5000

- Mechanical Speed: 60-4200

(L x W x H)

- Electronic Variable Speed: 50-5000

- Mechanical Speed: 60-4200

- 16-Speed Step Pulley: 80-2760

(L x W x H)

10” x 54” (254mm x 1371.6mm)

- Electronic Variable Speed: 50-5000

- Mechanical Speed: 60-4200

(L x W x H)

- Electronic Variable Speed: 50-5000

- Mechanical Speed: 60-4200

(L x W x H)

Vertical Mill = Essential Tool

Vertical mills are versatile machines that can perform a range of operations, including milling, drilling, and boring. They are an essential tool in the manufacturing industry and can produce high-quality parts with great precision.

Understanding the various parts and functions of a vertical milling machine is crucial for operating and maintaining these machines efficiently.

LeBlond offers a range of vertical milling machines in assorted sizes, each designed to meet the needs of specific industries and applications.

Please call us at +1 (888) 532-5663 and dial Option 2 to discuss pricing on our various models.

We look forward to hearing from you!

I will be training high school instructors on teaching the basics of machining on manual lathes and mills at the CITEA/MTTA summer conference at CALPOLYSLO. The dates are July 9-11, 2023.

I would like to use your manual lathe and mill presentations to augment this live “hands on” training in the Manufacturing Engineering machine shop at that conference.

Go the citea.org to get details on this conference.

I would like your help for this project.

John J. Chocholak

Board Member

California Industrial and and Technology Association (CITEA)

Manufacturing Technology Teachers Association (MTTA)

No problem John! We would love to help. Someone will reach out to you for more information.