New to machining and need to know more about the uses of a lathe?

Read on and get more familiar with this extraordinarily useful and historic machine tool.

Uses for a Lathe Detailed

Lathes are machine tools for shaping metal and wood. They do perform other functions such as cutting, grinding, drilling and facing. A lathe operates by rotating a workpiece around a stationary cutting tool. It essentially removes unwanted parts and leaves a nicely shaped workpiece.

A milling machine works oppositely. With milled tools, the workpiece can remain stationary while the cutter rotates.

The lathe is intended for the removal of material when exposed to cutting tools. This equipment has many uses. A few are woodworking, turning, thermospray, reclaimed parts and glass manufacturing processes.

Most well-built metalworking lathes also work for most solids, smooth surfaces and screw threads or helix.

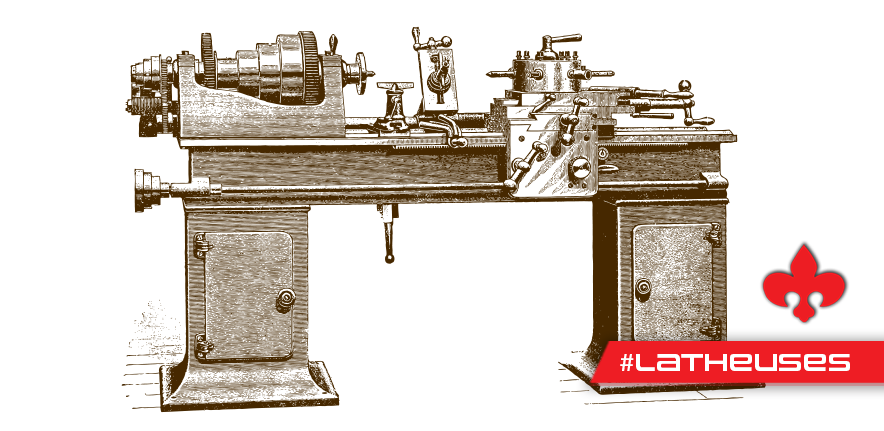

A Short History of Lathes

Lathes have existed for a while – since about the 13th century BCE. Think about a lathe’s similarity with a potter’s wheel.

Both share a long history and thrown pottery and lathes follow the same rule, but, on a lathe, the operator rotates the piece against a stationary cutting tool. Some basic machines allowed machinists to remove material freely.

Metal lathes and wood lathes were technologically enhanced and eventually developed into machines with integral heads. Each of these heads was installed on cross slides that extended across all the lengths of the lathing floor over which the workpiece rotated.

The First Lathe Tools

The first lathe machining tool was created over 3,000 years ago in ancient Egypt. This machining tool was one of the first recorded machines of humanity and was remarkably simple. It used a simple strap to spin the rig and needed a second operator to do the spinning.

Even then, it was a popular tool, and its use spread through the ancient world to Greece and Assyria. The Romans added their own innovation with the turning bow that allowed the user to do the turning themselves.

Middle Ages

During the Middle Ages, the invention of the pole lathe came about. Though it wasn’t much more complex than the lathes before, this lathe was powered by a pedal. This was a welcome advancement for those in the field of lathe work because it freed up the worker’s hands.

Industrial Revolution

During the 1800s, the steam engine was invented, ushering in the age of modern lathes. Modern lathes entered the scene at a particularly welcome time as the Industrial Revolution brought with it a huge increase in the production of trains, automobiles and ships as well as other machining tools. All of these required the use of a lathe for production.

These lathes were significantly stronger, more versatile and more efficient than the pole lathe of the Middle Ages that came before it. The 1800s machines are not much different than the manual lathe machine you would find in a machine shop today.

Types of Lathes

Designed specifically for metal workpieces, a metalworking lathe is also known as a metal lathe. Metalworking lathes support a wide range of metals and alloys including steel, aluminum, copper and iron.

Engine lathes are horizontally shaped machine tools that use special cutting tools to cut metal to create the desired shape. Finished pieces are used in automobile engines and machine engines.

A toolroom lathe is similar to an engine lathe except that it’s smaller in size and designed for precision cutting and an extremely accurate machining process.

A CNC lathe, or a computer numerical control lathe machine, is a machine tool where the workpiece is clamped and rotated by the main spindle while the cutting tool is mounted and moved in various axes.

These lathe tools have a tool holder that holds the lathe tool firmly in place during operation. The choice of tool holder depends on the accuracy and speed of cutting required. Each different type of tool holder will have a different level of balance and run out.

CNC lathes can produce a range of products from automobile frames and airplane engines to surgical instruments and garden tools.

Important Lathe Machine Tool Parts

The lathe bed is the main part of the lathe and is usually made of cast iron. The lathe bed provides a solid frame to which all the lathe’s main components are mounted.

A slide box is the control box for the feed movement of the lathe. Its mechanism turns the rotary motion of the light rod and the lead screw into the linear motion of the tool post.

A modern lathe typically has a power source that is an electric motor and can be configured as A/C, D/C, fixed speed, variable speed, reversible, single rotation and electronic braking. Not all motors drive through pulleys – some are direct drive.

Gearhead Lathe vs Variable Speed Lathe

The simplest way to remember this is that the gearhead lathe is like a manual automobile transmission and the EVS (or electronic variable speed) headstock lathe is like an automatic transmission.

The gearhead headstock uses a gearbox driven by a fixed-speed electric motor with a selection of gear ratios to select spindle speed. This type of lathe is typically more economical.

An EVS headstock lathe is driven by an inverter drive motor which gives you more control. When operating this lathe, the machinist adjusts the speed with a dial and can review the RPMs with a tachometer mounted on the control panel, allowing the operator to fine-tune the cutting speed.

The decision on which lathe is right for you would depend heavily on the lathe operation to be performed. Does your machine shop cut only one type of diameter or does it vary? Do you have to change speeds often? If your lathe operation varies and requires frequent changes in speed, you might want to consider the EVS headstock.

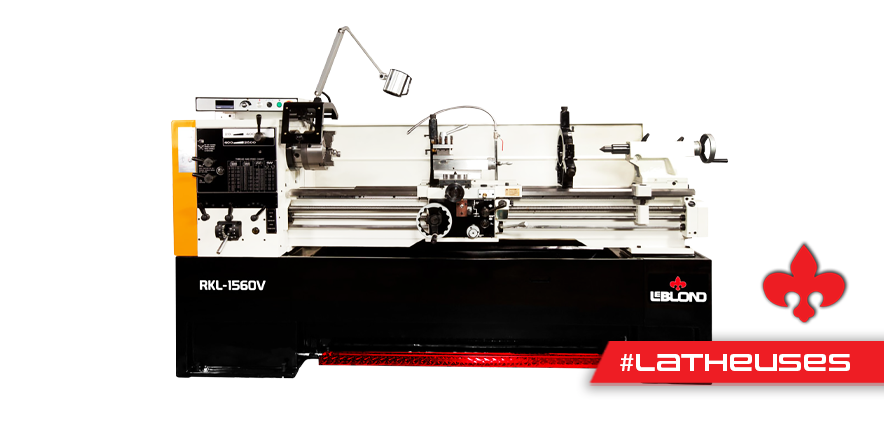

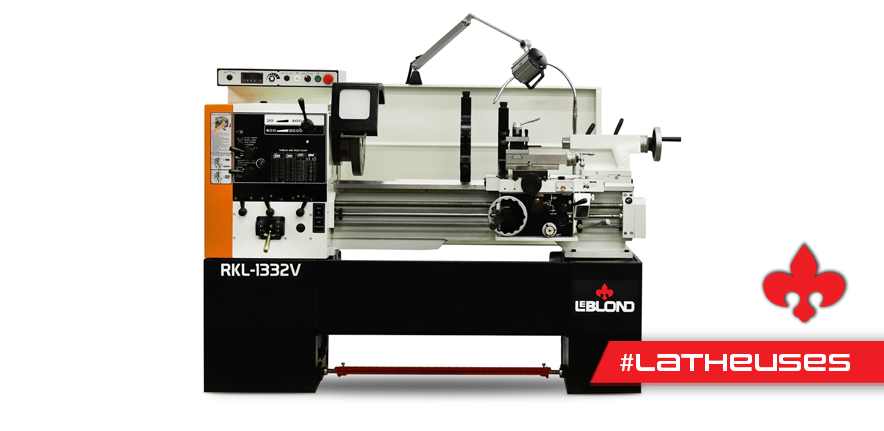

LeBlond Lathe Product Lines

Looking for engine lathes?

Try a LeBlond RKL manual lathe tool. LeBlond’s precision high-speed metal lathes and precision high-speed heavy-duty models feature a 14”-21” swing. The basic high-speed lathes have a center distance of 32″-60″ while the heavy-duty models feature a center distance of 40″-90″.

The swing indicates the maximum diameter of a workpiece that the lathe is able to rotate without hitting the bed. The distance between the lathe center will determine the maximum length of the workpiece that can fit into it.

To give you an idea of how much floor space is needed, these manual lathes can weigh anywhere from 2865 lbs to 4188 lbs, have a width and height of about 45”x75”, and have a length of anywhere between 81.5” – 115.”

If you need more power, you can try an RKL heavy-duty lathe machine tool with swings from 22″-30″ and centers between 57″-157″.

If you need an educational or good gunsmith lathe machine tool, try the RKL-1332G with a 14″ swing and 31.5″ distance between centers.

The RKL-1332 weighs 2865 lbs. The width and height measurements are 45”x75.” They are 81.5” in length.

Need pricing on a LeBlond lathe? Call +1(888) 532-5663 and select Option 2 (Monday – Friday 8am – 5pm Eastern). Or you can simply click the button below and customize your own Request for Quote.

We look forward to hearing from you!