Any doctor will tell you that good health practices will make you stick around longer. Good health practices for a LeBlond RKL Series manual lathe means effective preventative maintenance:

1. Clean & Wipe Down Machine Before and After Use

Use a clean, dry rag to wipe down the machine before using it. After you’ve finished your run, add a rustproof solvent to the rag and wipe the manual lathe down again.

2. Do NOT Use an Air Hose To Clean the Machine

An air hose can lodge chips and other debris under the four carriage wipers as well as the four wipers on the tailstock. Chips can get blown under the wipers and get stuck in the cast iron vitals of the manual lathe, potentially damaging it.

3. Oil the Machine After Use

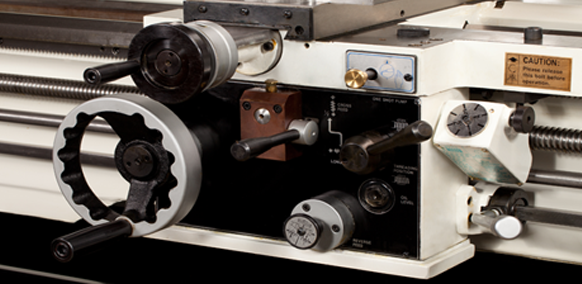

Just as you wipe it down, remember to check the various oil spots on the manual lathe. There are oil reservoirs on the headstock, QC Box and apron. On the RKL, there is another oil reservoir on the lead screw support block that is on the back of the machine and part of the bed assembly.

There are also several spring-loaded cups that open to add a few drops of oil. There are two on the tailstock and one on the compound. Also be sure to check the hand-operated lube pump on the carriage that the operator needs to pump every day.

Be sure to buy LeBlond 20 oil to lubricate your machine. To order LeBlond 20 oil, call LeBlond Ltd. at (888) 920-9852. For a more comprehensive list including diagrams of the various oil spots on your manual lathe, check out your RKL owner’s manual.

If you are interested in purchasing new K.O. Lee Economy Mandrels offered by LeBlond Ltd. or require OEM parts for your LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, call LeBlond Ltd. at (888) 920-9852. If you are interested in new LeBlond or K.O. Lee machines, call LeBlond Ltd. at (888) 920-9852.