LeBlond is known as a supplier for Standard Modern lathe parts like actor Bryan Cranston is known for more than Walter White.

Product Information

Three Tips to Cut Machining Costs

Evaluating Your Practices Can Cut Machining Costs Saving time, improving efficiencies, reducing waste are all ways to cut machining costs and increase margins for machining parts. However, putting the right tactics in place to achieve these cost cutting measures is...

Seven Tips for Cutting Different Metals With a Lathe

Adjustments may be needed to optimize the machining process when machining different metals with a lathe. Machinists should take precautions to avoid scrap and waste since metal hardness varies.

LeBlond 10% Off Summer Sale

Get 10% or even more off LeBlond and K.O. Lee machinery this summer of 2022.

Move Over, Santa! LeBlond Has Your Machine Tool Needs Covered

All year round and especially during the holidays, LeBlond beats Santa for supplying all your machine tool needs.

LeBlond Machine Tool Packages Are Sweet in Spring

Spring is sweet to save on the LeBlond Suite machine tool packages.

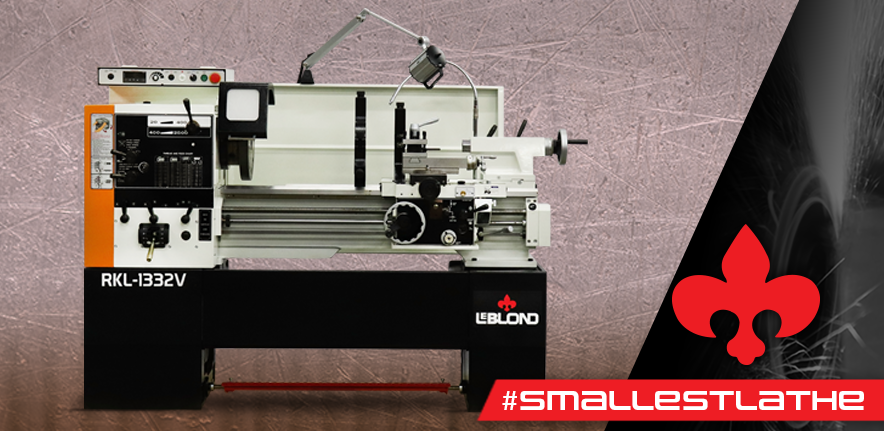

What Is the World’s Smallest Lathe?

The RKL-1300 Series is LeBlond’s smallest lathe and differs from a mini or desktop lathe, the smallest of which this post details.

The Whole Truth About Lathe Parts Replacement

It is a simple truth for all machine tools that perform challenging metal turning, cutting and boring: Parts eventually wear out. The continuous operation of lathes in a machine shop potentially wears out a variety of moving parts on the machine. The proper...

What Is the Purpose of a Tool Grinder?

Learn what a cutter grinder does and all the differenty types. You will also discover the primary features of K.O. Lee’s tool & cutter grinder models.