Table of Contents

- Tool & Cutter Grinders vs. Universal Tool Grinders

- Cutter Grinder vs. Angle Grinder

- Why Would You Buy a New Tool Grinder Instead of a Used Machine Online?

- Tool Cutter Grinding Applications

- Universal Tool and Cutter Components

- K.O. Lee Universal Tool and Cutter Grinder Custom Features

- The Name Says It All

- FAQs

A tool grinder (tool & cutter grinder) is an industrial machine used in machine shops to sharpen milling cutters, tool bits and other cutting tools. Though mainly used for sharpening, cutter grinders, as the name implies, are also used for grinding.

There are many types of cutter grinders. Let’s review the different ones.

Cutter grinders are not your coffee and herbal grinders; they’re industrial machines that can help you refine minor details with insane precision.

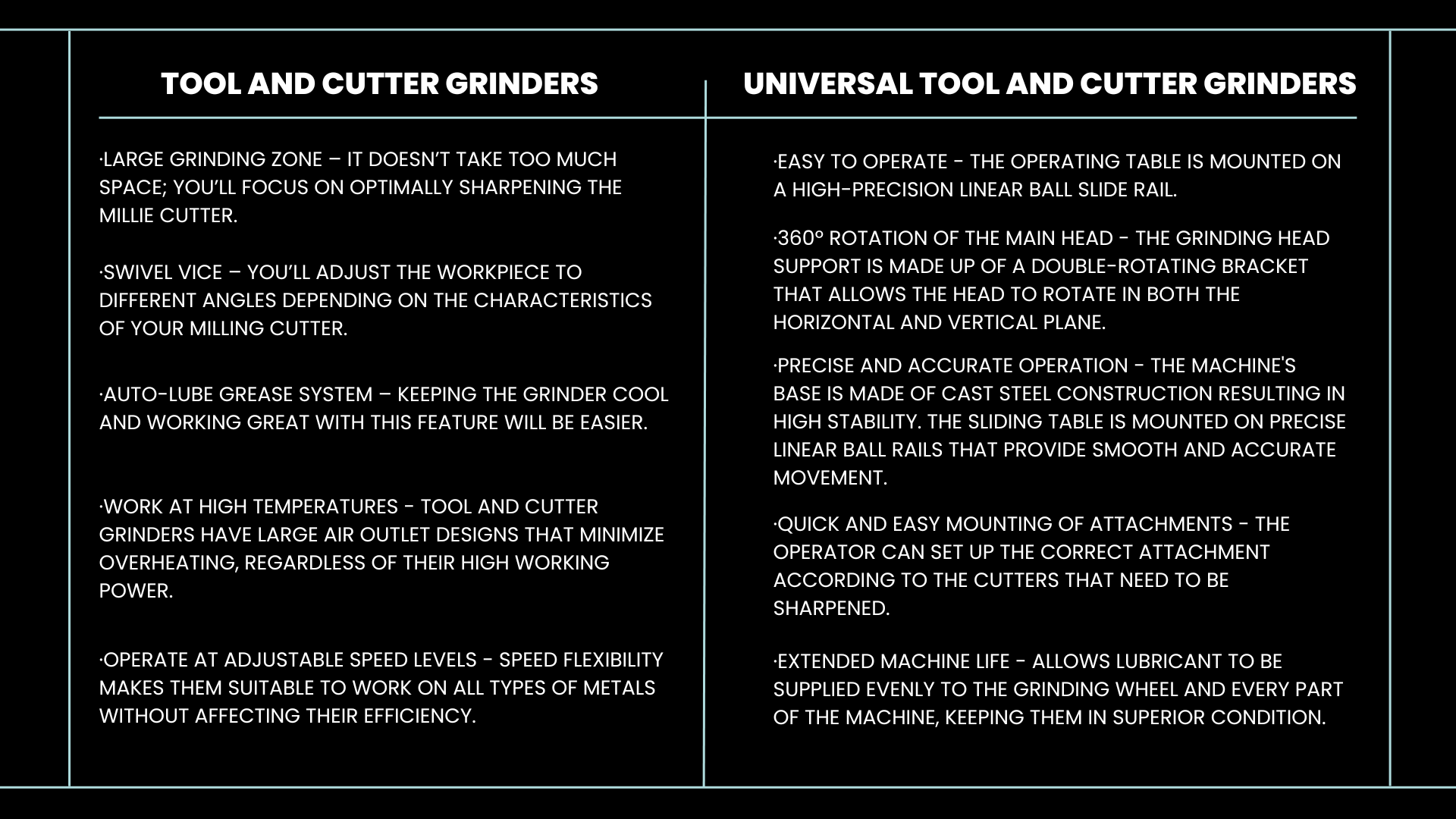

A Tool and Cutter Grinder is used primarily for metalworking and features an abrasive grinding wheel on a universal head with a vise, headstock, tailstock, and multiple attachments for holding the workpiece. With a tool cutter, you’ll have better bearings and a large wheel center to run smoothly, facilitating the sharpening of components such as lathe tools and inserts.

A Universal Tool and Cutter Grinder has a universal workhead that rotates and adjusts to any rake or angle at either horizontal or vertical positions.

Tool & Cutter Grinders vs. Universal Tool Grinders

Cutter Grinder vs. Angle Grinder

An angle grinder is a more inexpensive but powerful tool that can cut metal, aluminum, concrete, bricks, pavers, wood and other dense materials; you can sand and polish different surfaces to sharpen tools and grind materials. You can hold an angle grinder in your hand and buy one for a few hundred dollars.

Tool and cutter grinders are used mainly to sharpen and recondition multipoint tools like drills, reamers, milling cutters, taps, hobs, and broaches and for accurate grinding of angles of single-point tools. If tool grinders were transportation, an angle grinder would be a skateboard, while a tool & cutter grinder would be a sedan.

Why Would You Buy a New Tool Grinder Instead of a Used Machine Online?

- You have a guarantee it will work to perfection

- You’ll access the latest technology instead of decades-old machinery

- You’ll have customer service and support

- You may access installation and training

- You’ll have availability of spare replacement parts

- You’ll avoid unscheduled machine failures

Tool Cutter Grinding Applications

A Universal Tool Grinder has unique features and functions that allow:

- Surface Grinding, where a machinist can create a smooth surface on a flat surface with the grinding wheel

- Tool Grinding for sharpening

- Broach Grinding to remove material from a workpiece for axisymmetric shaping on the grinding wheel

- Internal Grinding of the internal diameter or ID of a workpiece

- Helical Grinding to produce precision spurs or helical gears on the grinding wheel

- Internal & Outer Cylindrical Grinding where the workpiece is mounted on centers for grinding

- Wheel Dressing Grinding is where a tool is used to dress or slightly trim the surface of the grinding wheel to “true it up”

- Step Grinding or a similar process to shimming

Universal Tool and Cutter Components

The Working Table of the grinder is the surface where the workhead rotates 360° to grind various cutting tools. For the most effective grinding, the working table can rotate 120° by 60° with the graduated scale attached.

With the Clutch, the speed of the working table’s feed is controlled. Speeds can be either high or low with a feed knob on both sides of the working table of the K.O. Lee Universal 40M or 60M Cutter Grinder. With these tools and cutter grinders, the handle on the right-hand side of the clutch controls lower speeds to prevent interruptions.

All Angles Wheelhead & Grinding Wheel

The Wheelhead and grinding wheel can grind at any angle requested by the operator. The inclination of the Wheelhead tilts easily up to 15° and has a 360° swivel on the horizontal plane.

The Angular Contact Ball is an essential component, designed in pairs to support the spindle and bearing. There are two pairs, tightened by nuts and held in place for support.

Tool Grinder: Less Maintenance & Greater Efficiency

No additional lubricant is needed on the grinding wheel swivel’s interior as it is already well-greased.

Another component is the precise Ball Groove of Conformation constructed of special alloy steel. This steel cable roll drives the working table, improving the operator’s efficiency.

K.O. Lee Universal Tool and Cutter Grinder Custom Features

Our Universal Cutter and Tool Grinders are custom machines with various features, including:

- A hydraulic cylinder that drives the x-axis in transverse motion.

- A servo motor driving the y-axis in cross-motion.

- A PLC touchscreen panel enables manual inputs.

The Centralized Lubrication System of K.O. Lee Universal Cutter Grinder machines allows lubricant to be supplied evenly to the grinding wheel and every part of the machine, keeping them in superior condition and extending machine life.

The two Tailstocks also partner cohesively with the Workhead to hold the workpiece steadily and achieve superior results. One Tailstock is fixed by a bolt, while the other is fixed by spring pressure.

The above features are not standard but add-ons to our manual tool cutter grinder.

Cutter Grinding

Many tool cutter grinder attachments enable the machinist to better customize his or her work on the grinding wheel. The attachments used by the machinist will depend on their needs and what they are creating.

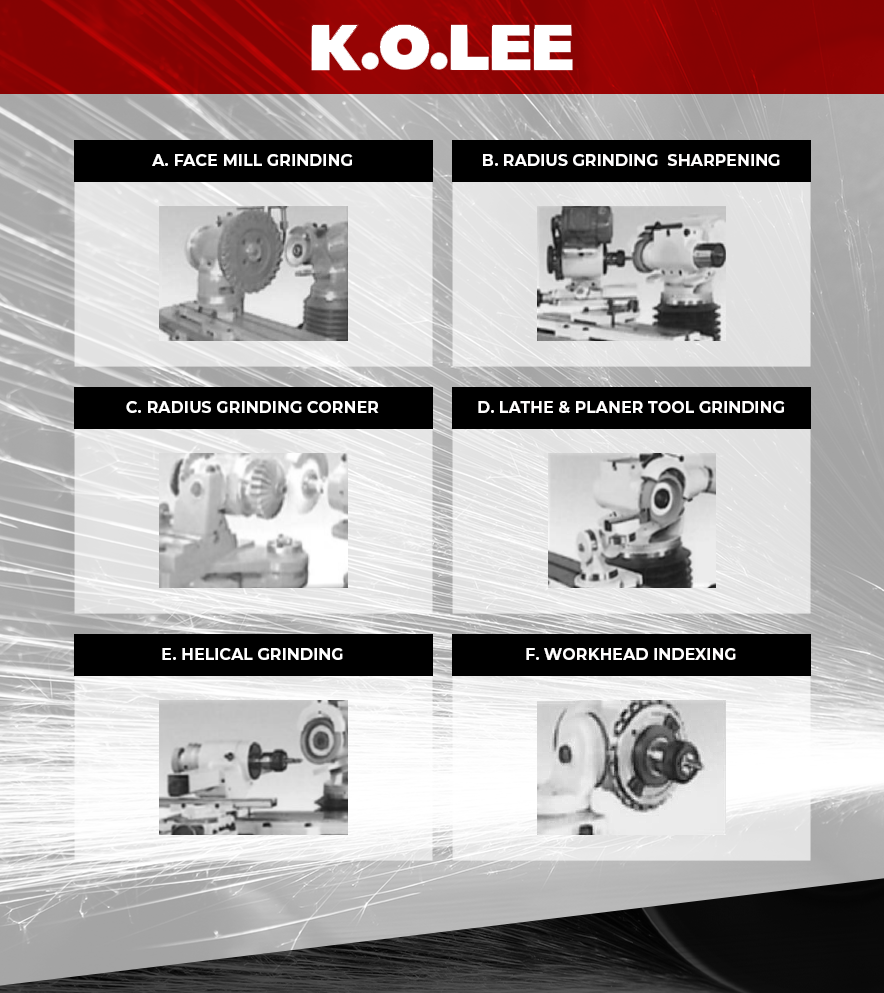

Multiple Custom K.O. Lee Universal Tool and Cutter Grinder Attachments Part 1

A. Face Mill Grinding makes it simple to set elevation and depression angles and grind large-size cutters and tools. With a horizontal swiveling base, this attachment allows a workspace up to a 15° angle.

B. Radius Grinding Sharpening enables the sharpening of the radii of ball end mills and styli. With an index plate mounted on the back of the workhead, the Radius Grinding allows for the indexing of straight flute cutters. There are two slide bases with micrometer adjustment and workhead.

C. Radius Grinding Corner is used to grind an accurate radius on the corner teeth of the face mill and shell end mills. Upon grinding, set the position by micrometers to prevent error.

D. Lathe and Planer Tool Grinding allow for the grinding of lathes and planer cutters, creating a large work support area. Set the cutters for grinding rake and relief angles.

E. Helical Grinding is an attachment used to grind relief and rake angles of spiral cutters or straight teeth of end mills, hobs, and center drills.

F. With Workhead Indexing, a machinist can reduce the need for tooth rest when grinding cutters. The indexing is simple and efficient when mounted to a standard workhead. The attachment comes with a plate that has 24 equal slots.

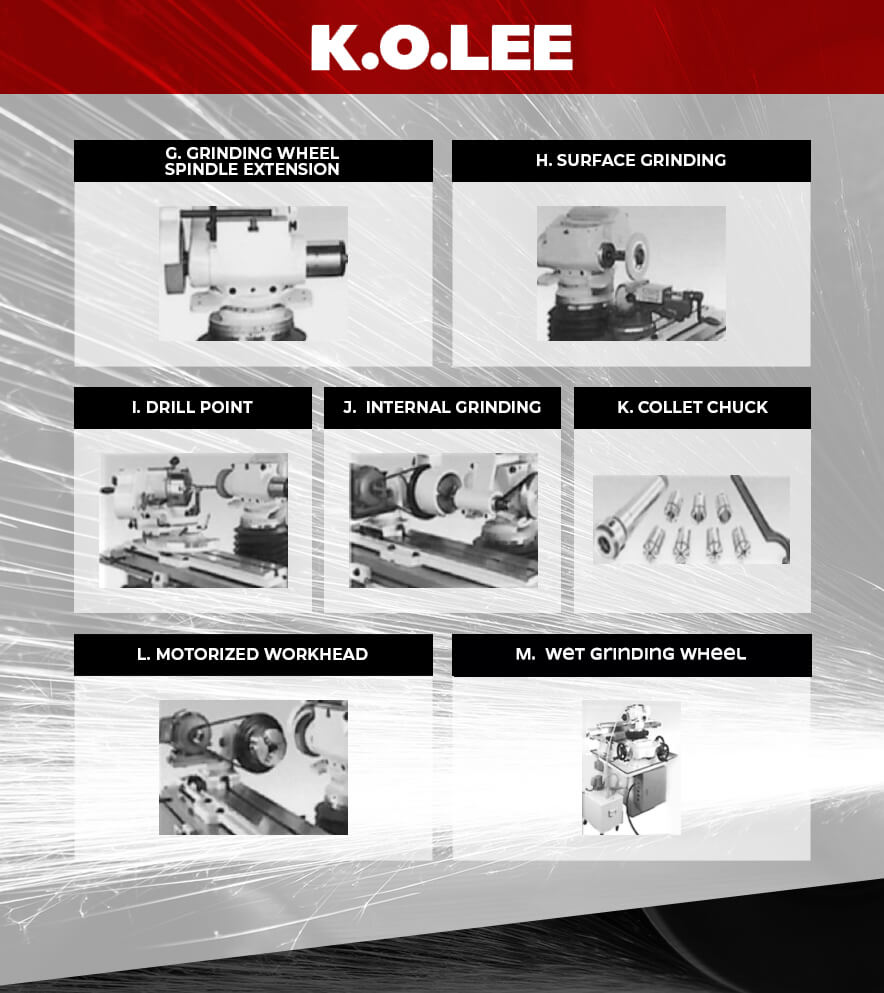

Multiple Custom K.O. Lee Universal Tool and Cutter Grinder Attachments Part 2

G. Grinding Wheel Spindle Extension is used for extended spindle applications with an extension of 3 inches. It contains cartridge-type construction and can easily be interchanged with a standard spindle.

H. Surface Grinding is used for both surface grinding and grinding bits. This attachment features a swivel vise and base with intermediate support that enables 360° horizontal and vertical swiveling.

I. A Drill Point is the most productive way to sharpen drills. To use, hold the drill in a precision six-jaw self-centering chuck.

J. Internal Grinding is used with another attachment, the Motorized Workhead. It is the best solution to grind internal capers.

K. The Collet Chuck is the ideal attachment when performing small cutter grinding jobs. Mounted right into the warhead’s taper hole, this chuck works seamlessly when grinding.

L. The Motorized Workhead is used for the face grinding of numerous tools and straight or taper cylindrical grinding.

M. Wet Grinding utilizes a Coolant Supply System for grinding operations that need coolant, such as surface, internal and cylindrical grinding.

The Name Says It All

The purpose of tool and cutter grinders is to sharpen a broad swath of tool bits and cutting implements and grind with a panoply of attachments and custom features.

If you want more information on K.O. Lee Universal Tool and Cutter Grinders, visit this page or call (888) 532-5663 and dial Option 2. We look forward to hearing from you!

FAQs

What is the purpose of a tool and cutter grinder?

Depending on the type of grinder you purchase, you may create a smooth surface on a flat surface with a grinder wheel, sharpening and removing material from a workpiece.

What are the advantages of a grinder?

A grinder can be used in a machining process that uses an abrasive wheel as the cutting tool or metal cutting process. It can work with rugged materials and at high temperatures.

What is the importance of a grinding machine?

They have multiple uses, but mainly to reduce the particulate size of various materials with precision. Some materials are difficult to grind or cut to a particular size while working with purely mechanical means.

What is the main objective of a grinding machine?

The main goal of a grinding machine is roughing and finishing flat, cylindrical, and canonical surfaces, as well as others. It is a machining operation used to improve the accuracy of a previously machined product.

What is a universal grinding machine?

It is a tool that grinds, files, and finishes workpieces made of metal. This machine’s construction and arrangement allow it to work with various materials.

What are the three common types of grinders?

The angle, surface, and die grinders. The angle is used for both construction and metalwork. Surface grinders are used in construction to provide a finished surface on an object. Die grinders are hand-held and are used for sanding and polishing.

What is the difference between a cylindrical grinder and a universal grinder?

Both the wheel and work head can be swiveled in universal-type grinders. A cylindrical grinder is used for cylinders, rods, and other workpieces. Universal grinding machines have a swivel table, headstock, and a head that can be rotated on its base.