If you want to buy a new car – manual or automatic transmission might be one of the first questions that you ask yourself. A stick shift (manual transmission) gives you more control and is less expensive. An automatic transmission is more expensive but is easier to use. This could apply when it comes to gearhead lathes compared to lathes with an electronic variable speed headstock.

Gearhead vs Electronic Variable Speed Headstock

Now let’s take this analogy to the new purchase of a metal lathe – gearhead or Electronic Variable Speed (EVS) headstock?

Similar to the automotive engine analogy, a gearhead headstock, like a manual transmission, is more inexpensive. This type of lathe uses a gearbox driven by a fixed speed electric motor with a selection of gear ratios to select spindle speed.

An EVS headstock is driven by an inverter drive motor. To put it simply, an EVS manual lathe gives you more control. When using the metal lathe, the operator adjusts the speed with a simple dial and can view the RPM’s on a tachometer mounted on the machine, allowing an operator to fine tune cutting speed.

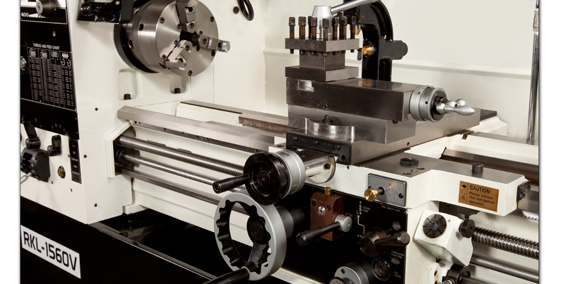

For example, LeBlond RKL Series Geared Head lathes offer sixteen fix speed selections. LeBlond RKL Series Electronic Variable Speed lathes offer infinite speed ranges. The RKL-1560V supplies a high torque in two ranges – low (20 to 400 RPM) and high (400-2500 RPM). The RKL-1960V provides three headstock gear ranges – low (30-125 RPM), medium (125-450 RPM) and a high range (450-2200 RPM).

Which is the better option – gearhead vs. EVS – depends on how you use the metal lathe. If you are a machine shop that doesn’t have the need for a wide range of job requirements, then the gear head is the better option – you cut one type of diameter and don’t have to fiddle with speeds. It makes more sense, therefore, to save money and go with the gearhead metal lathe.

More realistically, however, you probably are a machine shop that has a flux of jobs that require a need for varying speeds. You encounter a variety of diameters on workpieces that you have to cut and need varying horsepower. In this case, the additional cost of EVS metal lathe can be recouped by increased tool life and operator efficiency.

The gear head vs. EVS metal lathe argument also has ramifications when it comes to maintenance that we will explore in a future post.

If you’re interested in new LeBlond manual lathes, K.O. Lee grinders or need original OEM parts for LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, fill out a contact form here.