Table Of Contents

- Why Your Lathe Needs a Newall DRO

- Why Your Lathe New DRO Should be a Manufacturer Like Newall?

- Disadvantages of NOT having a DRO

- Advantages of HAVING a DRO

- Pay for the Newall Digital Readout System in as Few as 8 Weeks

- Get the Latest in Shop Tech with the Newall NMS 800

- Contact LeBlond for Pricing on a Newall Digital Readout

- FAQs

- KEY TAKEAWAYS

TL;DR

The primary purpose of a DRO or digital readout such as the Newall DRO, is to provide real-time feedback on the position of a lathe’s moving parts with a digital display that shows the position in a numerical format. In this post, we explain why you need a DRO for your LeBlond lathe and highlight the features and benefits of owning this powerful tool.

Why Your Lathe Needs a DRO like the Newall DRO?

A DRO, such as the Newall DRO, replaces traditional manual measurement methods such as vernier calipers or dial indicators.

With a new DRO, a machinist can enhance the capabilities of a lathe, improve precision, save time, and streamline the machining process.

It’s a worthwhile investment for any machinist looking to increase productivity and achieve higher precision in their work.

More importantly, you can save cash with a Digital Readout from a manufacturer like Newall.

How?

The DRO shows the precise tool position independent of the lead screw.

A machinist no longer has to read lines on grimy Vernier dials and other lathe controls. Counting hand-wheel revolutions and lead screw backlash compensation is no longer necessary.

A Newall Digital Readout on a LeBlond lathe gives you precision within five microns.

You’ll save time machining and increase productivity by 20-40%.

Why Your Lathe’s New DRO Should be a Manufacturer Like Newall?

LeBlond offers a variety of DROs like the Newall DRO. Here are several crucial reasons why you need one if you’re fully submersed in machining.

If you keep double or triple checking if you are reading your dial correctly, checking if your indicator didn’t bump, or keeping your scales clean — you need a new DRO.

A Newall has the performance you want to save time and money.

Disadvantages of NOT having a DRO

- Cross-Slides Have Backlash

Lathes utilize a cross-side to machine critical O.D and I.D dimensions.

- Tool Pressure is Exerted on the Cross-Slide

The turning workpiece exerts pressure on the tool, which shifts the cross-slide back against the screw.

- Vernier Dials Are Hard to Read

Counting hand-wheel revolutions is a must to avoid failures. The dials can fade to oil and debris buildup.

- Stopping & Checking Time is Non-Productive

It’s required to make frequent stops to check the parts with a scale, caliper, micrometer, and dial indicators.

- I.D. Work is Even Harder to Measure “Blind”

Setting up indicators and magnetic base holders is time-consuming. There’s always a risk of being bumped or moved.

- Step Lengths

Some lathes don’t have a dial on their axis or have the Vernier dial in irregular locations, making the carriage travel harder to read.

Advantages of HAVING a DRO

- Vastly Reduced Positioning Times

New DRO systems utilize linear scales mounted to the cross-slide and carriage axes of the lathe. Reading lines on Vernier dials, counting hand wheel revolutions, and lead screw backlash compensation is eliminated.

- Accuracy and Repeatability

Stop-check-measure steps are eliminated (save for final cuts). The Direct Diameter Reading feature reduces time on calculations and scrap.

- No Cleaning and Maintenance Required

They are robust and require less maintenance than traditional mechanical systems. They are not entirely maintenance-free, but they can withstand harsh work environments thanks to their sealed components, reduced calibration requirements, and solid-state technology. No mechanical wear characteristics require no cleaning or maintenance after long periods of operation.

- Tolerant to Shock and Vibration

DROs use solid-state electronics which are more reliable and less susceptible to mechanical failures.

- Ease of Installation

The combination of non-invasive installation, clear instructions, modular design, and user-friendly features makes a stress-free process for experienced machinists and those new to the technology.

- No Glass or Tape to Break or Scratch

Glass scales can scratch, break or misread due to condensation. Magnetic wire and scales fail due to chip build or loss of polarity.

Pay for the Newall DRO (Digital Readout) in as Few as 8 Weeks

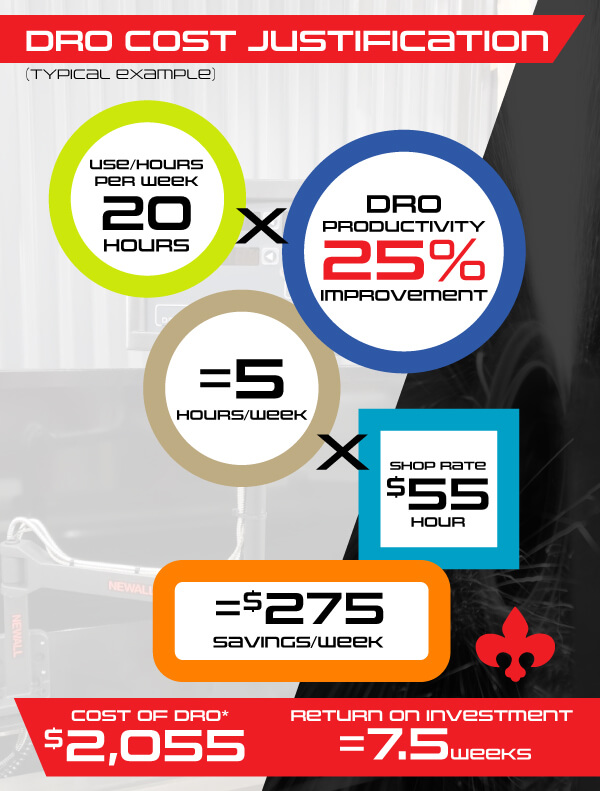

Join the Newall advantage! Let’s present a hypothetical demonstration of how digital readout systems like Newall pay for themselves quickly.

Suppose you average 20 hours/week on your LeBlond manual lathe and your shop rate is $55/hour.

We will use a 25% productivity improvement for your LeBlond lathe by utilizing a Newall Digital Readout (though this figure is low).

This increased productivity results in a 5-hour/week improvement.

Multiply that extra time saved by your weekly usage, and you are looking at $275 savings each week.

In this example, the Newall digital readout costs you $2,055.

The Return on Investment is Cost/Savings ($2055/$275) or 7.5 weeks to pay back your investment in digital readout systems with enhanced productivity.

You could have this critical lathe accessory paid off in two months or less than one business quarter.

Get the Latest in Shop Tech with the Newall NMS 800

The NMS 800 Digital Readout is the newest in Newall’s range of premium readouts.

This new Newall DRO hosts many productivity-enhancing features that will increase efficiency.

The NMS 800, when matched with Newall’s Spherosyn Serial and Microsyn Serial encoders, provides years of maintenance-free, trouble-free performance.

Newall’s linear encoders are simple to install and designed to provide consistent precision and reliability even under the harshest workshop conditions

All electronic and measuring components are sealed from the environment.

Here are some of the NMS 800 features:

- Clean, crisp PMVA LCD with a wide viewing angle

- Lathe, Mill, and General-Purpose functions

- Self-Sensing Encoder Input

- Available in 2, 3, or 4 axes

- User-definable function keys to shortcut to your most common features

- Linear and angular readings

- Stand-alone or panel mounting

Contact LeBlond for Pricing on a Newall DRO (Digital Readout)

Need to up your productivity game? Contact LeBlond for a Newall Digital Readout. We attend to all customers’ needs.

- If you have any specific questions about a Newall DRO or other Newall products, please leave a comment and we’ll be happy to help.

- If you need a Newall Digital Readout Installed, click or tap HERE.

- Or call us at (888) 532-5663 and select Option 2.

We look forward to hearing from you!

FAQs

What does DRO mean in machining?

It stands for “Digital Readout.” A Digital Readout system is an electronic device used to display the position of machine tool elements such as the X, Y, and Z axes on milling machines, lathes, grinders, and other machining equipment. It provides real-time feedback on the position of the machine’s cutting tool or workpiece.

How do DRO scales work?

It consists of a precision-ground metal or glass scale, which serves as a reference surface. The scale has evenly spaced grating marks or lines etched on its surface. These grating marks act as a measurement scale.

- The read head is a sensing device that moves along the length of the scale.

- The read head is mounted on the moving part of the machine, such as a milling machine’s saddle or the lathe’s cross-slide.

- The read head contains a light source (LED) and a photodetector (usually a photodiode).

- The grating marks on the scale interrupt the light path between the LED and the photodetector as the read head moves.

- Then, changes in the magnetic field happen and transform into electrical signals.

- The electrical signals are processed by electronic circuits within the display unit. , determining the position of the read head relative to the scale’s grating marks.

- The machine’s position is displayed along the X, Y, and Z axes or any other dimensions.

How does a digital read-out work?

They provide precise and accurate measurements of machine tool positions, helping operators and machinists perform various tasks with higher efficiency and precision. It reduces human error and eliminates the need for manual measurement tools such as vernier calipers or dial indicators.

Can magnetic DRO scales be cut?

Doing so could cause several issues:

- It can disrupt the pre-defined magnetic pole pattern, leading to inaccuracies in the position sensing.

- Cutting the scale could interrupt the magnetic field pattern and cause irregularities in the signal, leading to erratic or unreliable readings.

- Cutting a magnetic scale to a shorter length might restrict the effective travel range, limiting the machine’s capabilities.

It’s essential to adhere to the manufacturer’s guidelines and recommendations to ensure the proper functioning and longevity of a Digital Readout system.

What is the output of DRO scales?

It’s typically in the form of electrical signals that represent linear or angular displacement. These signals are generated by the read head as it moves along the length of the scale and detects changes in position. The output signals can be of different types, depending on the sensing technology used in the scale.

💡KEY TAKEAWAYS

- A Digital Readout can significantly enhance the capabilities of a lathe, improve precision, save time, and streamline the machining process.

- They utilize linear scales mounted to the cross-slide and carriage axes of the lathe, eliminating common troubleshooting issues like having to count hand-wheel revolutions to avoid failures.

- Newall is a premiere brand of DROs. The NMS 800 is the model Newall DRO, promising game-changing productivity gains to machine shops and educational institutions.