In this post, we will discuss punch press parts and, specifically, those of Johnson Press.

Punch press in use at a knife factory. Courtesy Taro Taylor via wikipedia.org

What is a Punch Press?

A punch press is a type of machine used to cut holes in material – mostly any ferrous metals and even plastic. It can be small and manually operated and hold one simple die set, or be very large, CNC operated, with a multi-station turret and hold a much larger and complex die set.

Regardless of size, all punch presses use a die set to complete the punching process. Male punches and female dies make up a die set. As these pieces come together during operation, the sheet metal is shaped or cut into a predetermined form.

Punch presses are characterized by variables such as

- Frame type

- Mechanism of delivery of power to the ram

- Size of working area

- Single or multiple-station

- Force rating

- Speed of productivity

- Speed of movement without shock

- Maximum weight of workpiece

- Safety features

- Power consumption

They are usually referred to by their tonnage and table size. In a production environment, the 30-ton press is typically the machine that is used today.

What is Johnson Press?

In 1937 in Elkhart, Indiana, Johnson Machine and Press Division of Bontrager was formed and named after the chief engineer.

Early machines were light tonnage OBI (open back inclinable) in the 16 to 60-ton range and were manufactured exclusively with a mechanical pin-type clutch. In the late 1940s, OBI presses with 90-ton capacity were added to the product line.

By the early 1950s, air clutches were added to Johnson presses including the 116-ton model 10 punch press. In addition, a flywheel or back geared drive was made available and a heavy-duty tie rod was constructed. Straight side and gap presses were also added.

In 1957, the Johnson plant was moved from Elkhart to South Bend where South Bend Lathe purchased the line and continued to manufacture the product until 2002. In September of 2001, LeBlond Ltd acquired Johnson Press’ service parts business from South Bend Lathe, allowing their company to take over providing OEM replacement parts to those in the metalworking industry.

Johnson Press Parts

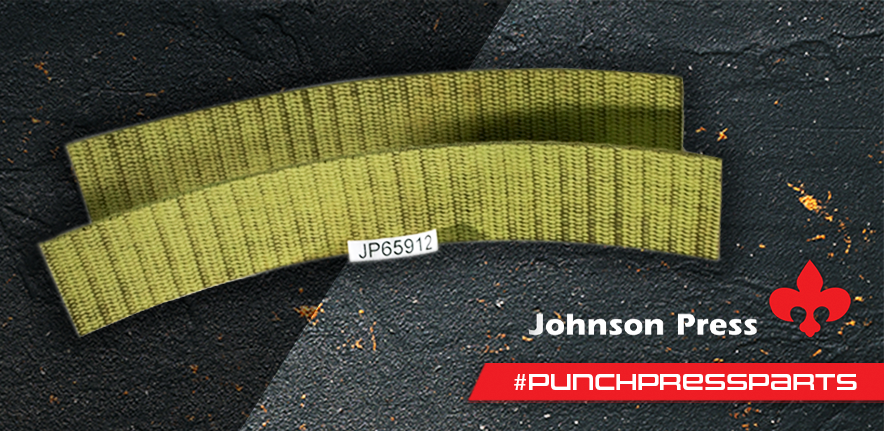

| Johnson Press Parts | Part Number | Part Description |

|---|---|---|

| Brake Lining | JP65912 |

|

| Lockbolt | JP12505 |

|

| Air Clutch Quick Release Valve | JP13423 |

|

| Ball Seat | JP03018 |

|

If you are in need of OEM replacement parts for your Johnson punch press equipment, click the button below or call us at +1(888) 532-5663 (Monday – Friday 8am – 5pm Eastern).

We look forward to hearing from you!