TL;DR

This blog post details the components that make up a drill press — a stationary or benchtop power tool designed to bore precise holes in wood, metal, or plastic. We explain the drilling machine’s functions, safety requirements and lubrication guidelines, exploring the Deka Drill press in particular.

Introduction

A drill press like the Deka Drill can drill material, counterbore it, or chamfer it.

Although production of the machine was discontinued in the early 2000s, we at LeBlond still replace spindles and other OES Deka Drill parts.

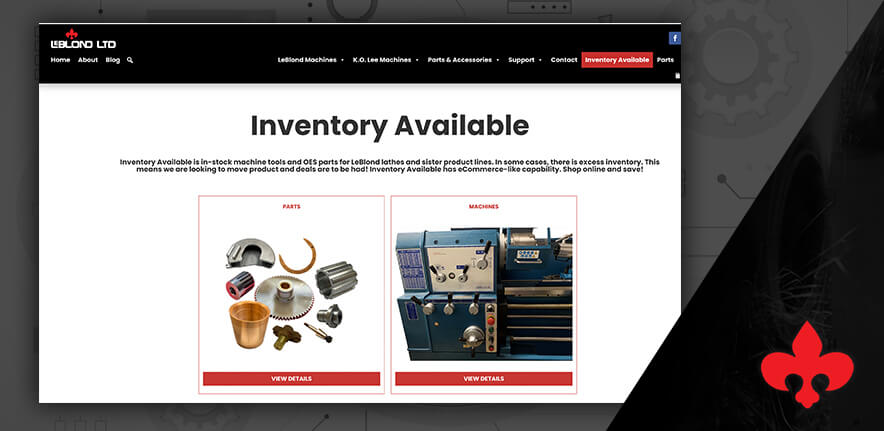

Click or tap HERE to find essential parts on LeBlond’s Inventory Available online feature. It’s an efficient way to request the exact part you need with our eCommerce-like tool.

Table of Contents

- TL;DR

- Introduction

- Overview of Drill Presses

- Drill Press Setup

- Unique Deka Drill Press Features

- Drill Press Parts & Functions

- Drill Press Safety

- Drill Press Lubrication

- Contact LeBlond for Common Deka Drill Parts

- Key Takeaways

Overview of Drill Presses

A drilling machine stands out as a versatile drilling and tapping machine engineered to excel in a diverse range of operations, including drilling, tapping, counterboring, chamfering, and similar tasks. It’s one of the most effective tools that features motors ranging from 3 to 15 horsepower and spindle speeds spanning from 166 to 3124 RPMs.

Drill Press Setup

When unpacking a new or legacy machine, you should remove heavy grease from machined surfaces, using a brush and a non-toxic, non-flammable solvent. You should then wipe these areas with a clean cloth and apply oil to protect unpainted surfaces from rusting.

Once the drilling machine is positioned, leveling becomes critical, particularly when coolant is in use.

Precision leveling involves ensuring evenness across the table slots and parallel with them, utilizing the adjusting screws in the machine base to distribute weight uniformly across all four corners of the base.

Unique Deka Drill Press Features

This machine’s features ensure efficiency in machining operations – it was manufactured for versatility and precision

Its remarkable versatility extends to its adaptability with adjustable brackets, fixed-center cluster boxes, and various jigs and fixtures, ranging from straightforward work-locating plates to complex master die-set type fixtures.

The spindles go through double universal joint assemblies that enable a precise location and secure connections to gearbox take-off stubs, eliminating the presence of loose shafts or joints.

A distinctive feature is the vertical movement of the power feed work table, operated by hydraulic power, facilitating cutting tool adjustments.

The hydraulic power unit is a separate assembly containing the motor, pump, filter, and reservoir with conveniently located electrical and hydraulic controls at the front of the table.

Additionally, a separate coolant system (comprised of a motor, pump, reservoir, hose, and shut-off valve) is equipped with controls conveniently situated on the front table for efficient operation.

Drill Press Parts and Functions

What makes up a drilling machine and what do these components do?

| Part | Function |

| Base |

|

| Column (Pillar) |

|

| Head |

|

| Spindle |

|

| Sleeve (Quill) |

|

| Motor |

|

| Drive Belt & Pulley |

|

| Drill Chuck |

|

| Feed Lever (Hand Wheel) |

|

| Table |

|

Do you have a Deka Drill and need parts?

Check out our online Inventory Available tool where you can source the most common OES components.

Drill Press Safety

This is paramount to ensure the operators’ well-being and the machine’s efficient operation.

Safety guards, a standard feature on drilling machines, must always remain in place during operation to shield operators from flying debris & moving parts.

Additionally, operators should wear appropriate personal protective equipment, such as safety glasses or goggles, to safeguard their eyes and, if necessary, hearing protection due to the machine’s noise.

Securing workpieces is crucial to prevent any unintended movement during drilling, reducing the risk of accidents and ensuring precise results.

Moreover, selecting the correct speed and feed rate, keeping hands clear of moving parts, and knowing the location of the emergency stop button are vital safety measures.

Routine maintenance, tools inspection, a clean workspace, & familiarity with emergency procedures further contribute to a safe environment.

Adhering to these guidelines and the manufacturer’s specific safety instructions is key to preventing accidents and injuries during operations.

Drill Press Lubrication

Proper lubrication not only prolongs the lifespan of various components but also contributes to the precision and safety of drilling operations and their tools. It ensures a smooth and efficient operation.

DTE 26 hydraulic oil is the best lubricant for a drill press. Contact LeBlond at +1 (888) 532-5663 and dial Option 1 to purchase.

Here are the best practices to lubricate your drilling machine per component:

Spindle Motor Bearings

- Check every six months

- Do not over-grease

- Add grease before removing the sump screw.

- Lubricate universal joint drives

- Apply DTE 26 with a brush on joints every four hours of operation

Spindles

- Daily lubrication

- Oil from a squirt can be mobile velocity #10 (or equivalent)

RAM Guides

- Daily lubrications

- Use a grease gun on four fittings

Transmission Gear Train

- Only 6 gallons required

- Check every two weeks

- Keep filled to sight level gauge drain & refill once each year

- Use DTE 26 or Mobil compound EE (or equivalent)

Gear Case

- Check weekly

- Do not over-grease

- Check weekly for leakage at hex takeoffs

- Do not grease unless leakage occurs

- Should be replaced every two years

- Use DTE 26 or Mobile PLEX EP #1 (or equivalent)

Hydraulic Motor Bearings

- Check every six months

- Do not over-grease

- Lubricate according to the manufacturer’s specifications

Hydraulic Unit

- 20 gallons required

- Check every two weeks

- Keep filled to sight leverage drain and refill when dirty or a minimum once every year

- Replace filter with oil change

- Use DTE 26 or Mobile DTE oil medium (or equivalent)

Contact LeBlond for Common Deka Drill Parts

We’ve delved into the key components, tools and functions of drilling machines, emphasizing the importance of safety measures and proper maintenance for smooth and accident-free operations.

LeBlond keeps these machines operational with OES parts and service support.

From adjustable bracket spindles to hydraulic power for vertical table movement, these machines offer many features and adaptability options, making them a valuable asset in various industrial settings.

Here are some common replacement parts that LeBlond usually has in stock and can ship as fast as the next day:

- Bracket Assy 1 5/8 (Part # DKPA8240MB1)

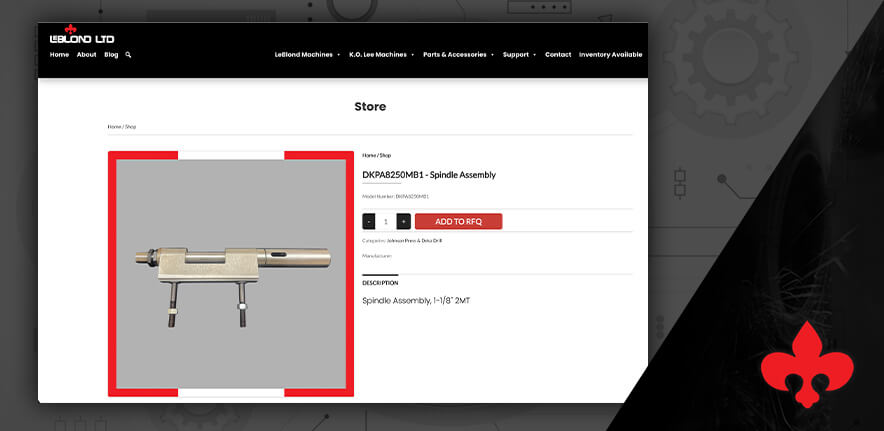

- Spindle Assembly, 1-⅛” 2MT (DKPA8250MB1)

- Shaft Spindle ¾ HEX (DKPT516MB1)

- Bracket (DKPT8105MB1)

- Spindle, Combination 1-⅛ (DKPT8149MB1)

- Spindle, 1-⅛ 2MT, Drilling (DKPT8250MB1)

- Spindle, ⅞, 1MT (DKPT8252MB1)

- Yoke, Small Hole (DKPT8279MB1)

- Gear, Spur (DKPT8454MB1)

If you need components, please contact us:

- Please leave a comment, and we’ll be happy to help.

- Call a LeBlond Customer Service Representative at +1 (888) 532-5663 and dial Option 1 (Monday – Friday 8am-5pm ET)

- Or visit our Inventory Available tool and submit an RFQ online with ease.

We look forward to hearing from you!

💡KEY TAKEAWAYS

- Drilling machines are designed for efficient production on a wide range of operations, including drilling, tapping, counterboring, chamfering, and more.

- The base, column, head, and spindle are some of the most common drilling machine parts with versatile functions.

- LeBlond keeps these machines operational with OES parts and service support.

- Regular maintenance, including lubrication, is necessary to keep them in good working condition. DTE 26 is the best oil to lubricate a drill press.

I have a Dayton 5Z146B drill press and do not have a base for it.. Dimensions of the pedestal on the tube are as follows…

OD – 5.4875″

Base hole for tube ID – 2.8565″

Four hole base – OD from hole to hole is – 5.0464″

Hole size for the four holes is .4515″

Do you have cast iron base that may work for this drill press..

Thanks for your question, Hilton. Someone will contact you. For immediate service, call 888-532-5663 Option 1.