TL;DR

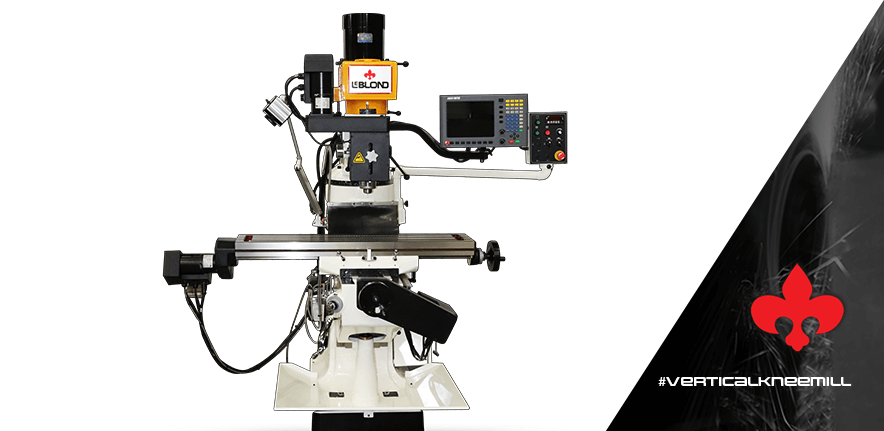

A vertical knee mill is a versatile tool that allows an operator to perform a wide range of tasks such as facing, slotting, drilling or boring. This blog post explores the versatility of LeBlond’s lineup of manual mills and CNC milling machines.

Meet John from Chattanooga

When not training the younger machinists in the Volkswagen shop, John spends his free time dreaming of retirement, picking a slide guitar and even an acoustic one.

See John likes versatility.

In the shop, he needs a milling machine that can handle a variety of tasks required for him to fix the plant machinery.

What John really needs is a machine that can handle Chet Akins AND Ry Cooder.

John, meet a LeBlond mill.

It’s got versatility in buckets.

Keep reading to learn why and more details on our milling machine lineup.

Table of Contents

- TL;DR

- Meet John from Chattanooga

- Understanding Knee Mill Machines

- Key Mill Characteristics & Features

- LeBlond’s Mills & Specifications

- Manual Milling Machine Standard Equipment

- Contact LeBlond for Pricing on a Versatile Mill

- Key Takeaways

Understanding Knee Mill Machines

Let’s get technical on mills.

Yale University has a nice technical summary:

Mill controls may be manually operated, computer numerically controlled (CNC), or a combination of both. This type of machining and material removal are typically made by a rotary cutter held in a spindle. Cutting options are more sophisticated and variable than a drill press by a moveable table and/or vise (x and y-axes) and vertical spindle movement (z-axis). Many mills also have a conventional rotatable turret for the upper cutting head which provides even greater machining options (b-axis).

It’s good to point out that CNC machines are automated, meaning they are controlled by computer programs (G-code) that guide its movements and toolpath.

Key Mill Characteristics & Features

Knee mills are a widely used tool in manufacturing and metalworking operations.

Knee mills are a crucial tool in the machining industry, known for their vertical spindle orientation.

This unique characteristic allows mills to perform both horizontal and vertical movements, providing flexibility in machining operations.

The heart of knee mills is their adjustable knee, which lends the machine its name. This movable column supports the worktable and enables precise adjustments, which is crucial for positioning workpieces and cutting tools at the desired height.

This versatility makes knee mills suitable for a wide range of tasks, from face milling and drilling to slotting, reaming and tapping.

Traditionally, knee mills are operated manually with machinists using handwheels, levers and dials to control the movement of the worktable and cutting tool.

This manual control allows for fine adjustments but can be labor-intensive.

However, in the modern era, some knee mills have been equipped with digital controls, such as Digital Read Out (DRO) systems or even full CNC (Computer Numerical Control) capabilities.

CNC milling machines are known for their high precision and accuracy in machining various materials.

These advancements provide automation and programmability, significantly enhancing precision and efficiency in machining operations.

Thanks to the use of conventional tooling and accessories, such as end mills, face mills, collets and drill bits, knee mills are suitable for a wide range of materials, including metals, plastics and composites.

In short, knee mills are truly versatile machines for a machinist like John from Chattanooga.

LeBlond’s Mills & Specifications

LeBlond has three manual mill lines

Below is a snapshot of specs to determine what is the best machine for your shop.

Want the information condensed?

Watch our one-minute video that summarizes the specs:

- Working Surface: 9”x42” (230x1067mm) or 9”x48” (230x1220mm)

- Maximum Workpiece Weight: 750lbs (340kg)

- Main Motor: 3HP

- Spindle Speed (RPM):

- 80-2760 (16 Speed Step Pulley)

- 60-4200 (Mechanical Variable Speed)

- 50-5000 (Electronic Variable Speed)

- Floor Space (L x W x H): 86.5”x63”x 82.7” (2197x1600x2100mm)

- Net Weight: 2380lbs (1080kg)

- Working Surface: 10”x54” (254×1370 mm)

- Maximum Workpiece Weight: 946lbs (430kg)

- Main Motor: 3HP

- Spindle Speed (RPM):

- 60-4200 (Mechanical Variable Speed)

- 50-5000 (Electronic Variable Speed)

- Floor Space (L x W x H): 101.25”x90.5”x84.65” (2572x2300x2150mm)

- Net Weight: 3350lbs (1520kg)

- Working Surface: 12.5”x58” (315x1470mm)

- Maximum Workpiece Weight: 992lbs (450kg)

- Main Motor: 5HP

- Spindle Speed (RPM):

- 60-4000 (Mechanical Variable Speed)

- 50-5000 (Electronic Variable Speed)

- Floor Space (L x W x H): 109.13”x94.5”x93.5” (2772x2400x2375mm)

- Net Weight: 3968lbs (1800 kg)

Manual Milling Machine Standard Equipment

All three manual knee mill lines share helpful standard features, including:

- Electrics: 230V/3PH/60Hz **other voltages available

- Ground and hardened column slideways

- Precision-hardened quill, ground, and chrome plated

- Cast iron hardened and ground table with Turcite B coated ways

- Multi-point saddle, knee, table and ram locks for high rigidity

Contact LeBlond for Pricing On a Versatile Knee Mill

If you’re like John from Chattanooga and need a versatile knee mill that offers the quality of the LeBlond name, excellent service and OES parts support, please reach out:

- Please leave a comment, and we’ll be happy to help.

- Call a LeBlond Sales Engineer at +1 (888) 532-5663 and dial Option 2 (Monday – Friday 8am-5pm ET)

- Or visit THIS PAGE.

💡KEY TAKEAWAYS

- Knee mills are capable of performing various tasks, including milling, drilling, boring and more.

- LeBlond has three machine lines, including a CNC model for even greater precision and productivity.

- LeBlond additionally offers service and parts support for their mills. Contact us for pricing.

Please send video of the LVM 1258 Vertical Milling Machine.

Is this comparable to the Bridgeport Series II ?

Please advise,

Danny Critz – Owner – Martinsville machine Works, Inc.

Martinsville, VA 24112

Danny, as the post details, give us a call at 888-532-5663 and select Extension 2 (M-F 8am – 5pm ET). We gather all your questions and discuss a video. Thanks.

Looking for a South Florida Distributor?

This is Rick Schoen of Florida Machine Tool Supply & Service

Born and raised in Owensville Ohio

Have 45 years in the machine tool Trade/Business.

Have 6 full time outside skilled service engineers.

Moving to a larger facility here in Pompano Beach Florida

We have serviced your lathes in the past 12 months at Florida State

Rick, give us a call at 888-532-5663 Extension 2 to discuss. Thanks.