Get Creative When Machine Shop Floors Get Cramped Precautions Machinists Can Take to Avoid Common Machinability and Material Selection Pitfalls Squeezing into an old pair of jeans that previously fit comfortably but are now too tight for your waistline is similar to a...

Scott Hasson

Machining Complex Metal Parts Requires Simple Solutions

Machinists must possess a deep understanding of machining principles, tooling, materials, & machine capabilities to produce complex quality parts. Know these 6 solutions to machining complex part pain points.

Best Solutions for Machinability and Material Selection

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

Top 7 Solutions for Tool Wear and Breakage

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

Ten Fixes for Small Part Manufacturing Pain Points

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

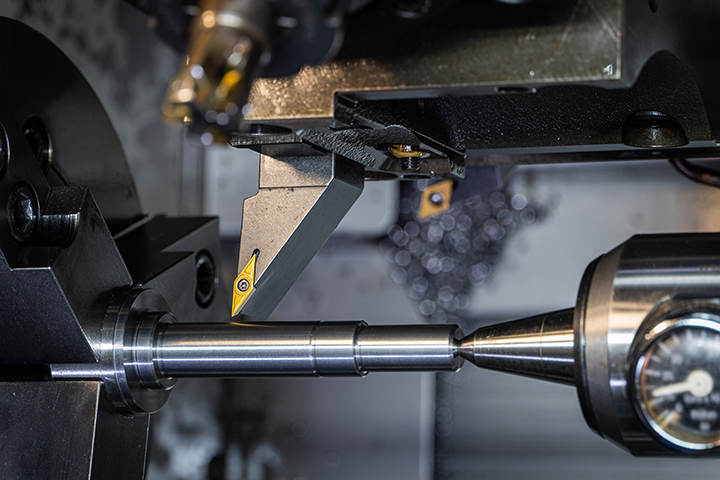

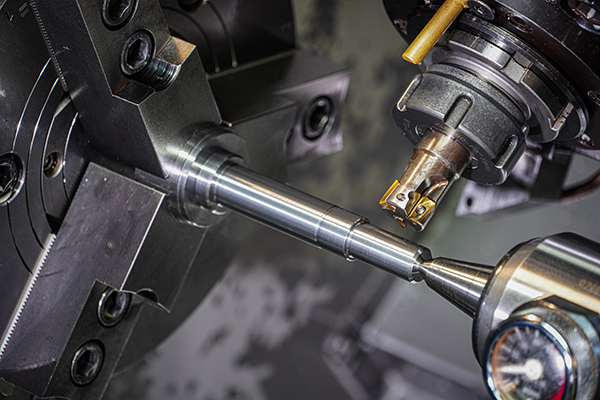

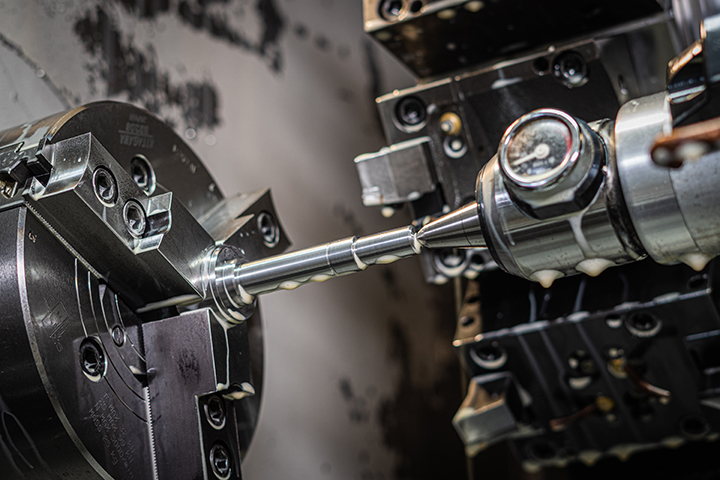

Five Lathe Tips for Cutting Extremely Large Parts

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Six Lathe Tips for Cutting Extremely Soft Metals

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Five Lathe Tips for Cutting Extremely Hard Metals

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Master Six Lathe Tips to Improve Your Output of High-Quality Workpieces

Become a manufacturing super star by following these 6 lathe tips. When put into practice they will greatly improve the final output on finished parts.