When was the last time you leveled your lathe?

If you haven’t leveled your lathe in the last 6 months, then your machine is probably due for a checkup. There are many ways a lathe can become unleveled. Common reasons for re- leveling your lathe include:

- Forklifts bumping the lathe

- Misuse or mishaps. An incident that can wreck the tooling can also put the lathe out of level

- Environmental changes. Even a change in the ambient temperature of the shop can throw off the level

Why is it important to perfectly level your lathe?

By getting the lathe level, you are assuring the most optimal performance of the lathe. There will be less scrap and waste. This is especially important when you are turning expensive metal or complicated parts. The life of the tooling can be extended since there is not any uneven pressure applied to the wrong part of the inserts. Mandrels can get bent if the level is off. Any minor offset can cause a twist in the bed and the tailstock can get out of alignment. Any misalignment can create unwanted tapering of a part. If you are machining to tight tolerances, you will want to make sure the level is as perfect as it can be for both the X-axis and Z-axis.

Leveling best practices

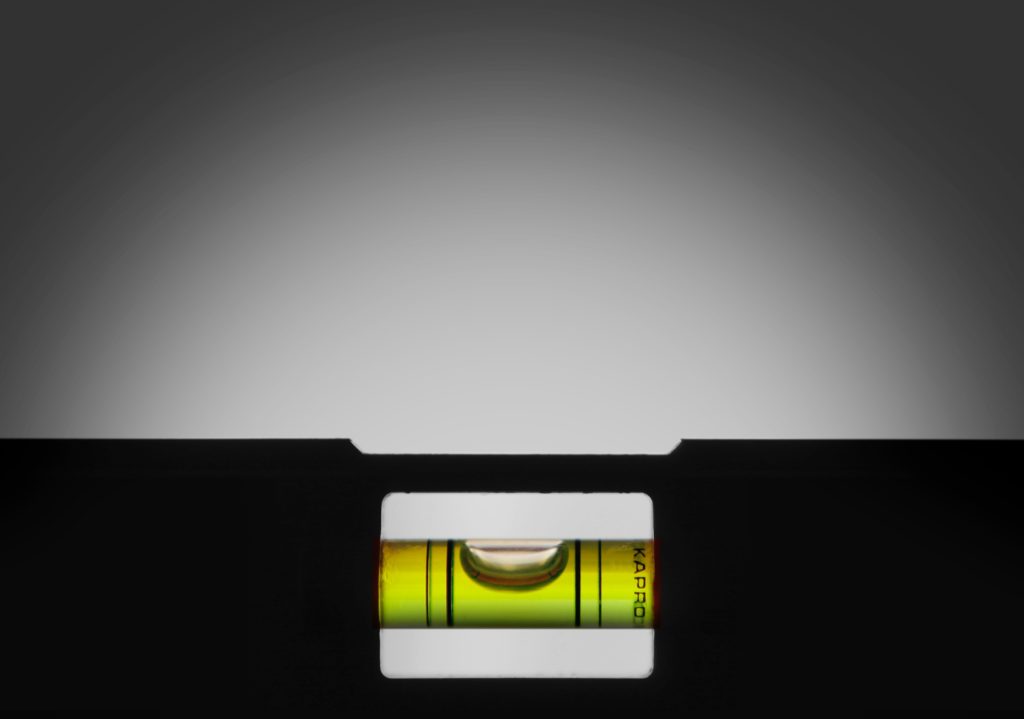

Before levelling your lathe, you’ll need a precision level that has been well-calibrated. Two levels are recommended, but not necessary.

For some of the larger lathes, you need to start with the inside legs to assure the bed is precisely leveled. The outer legs that provide support and stabilization for the machine get checked after inner legs are set. Clean debris from the bed and the precision leveling tool to avoid any distortion of the level. Even as much as a hair can cause the level to be off. Check the level in both the X-axis and Z-axis. Be sure to handle your level from the sides as temperature differences in the level can cause temporary distortion, giving an inaccurate reading. When in doubt, allow the level some time to reach an even temperature.

When QA checks show parts are getting out of control, it is important to perform a level check. Re-leveling your lathe will save time, avoid scrap and prevent premature wear to the machine. Taking the time to make sure the level on your lathe is as close to perfect as possible will keep your machine shop running smoothly.