Consider These 5 Tips for Cutting Extremely Hard Metals

Gain experience through practicing the following metalworking techniques

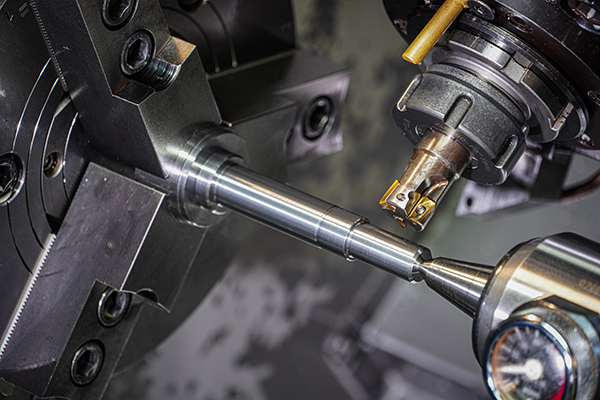

1. Select the Right Tooling

Choose cutting tools that are specifically designed for hard materials. Carbide inserts and diamond-tipped tools are often ideal for hard metals like stainless steel, titanium or hardened steel. Look for carbide tooling made of cemented tungsten carbide particles held together with metal binders such as cobalt. Typical hardness of tungsten carbide tooling falls within 8.5 to 9 on the Mohs scale. Diamond tooling has the highest rating of 10 on the Mohs scale. One distinction is that diamond tooling can withstand temperatures up to 1000˚ C versus carbide’s 600˚ C before degradation. Ensure the tool geometry and coatings are suitable for the material.

2. Use Slow Speeds and Heavy Feeds

Slow and steady wins the race when working with hard metals. Run the lathe at slower speeds to minimize heat generation and tool wear. Employ heavy feed rates to maintain a consistent chip load. When the cutting speed is reduced, the tool spends more time in contact with the workpiece leading to more controlled cutting forces. Be aware that increased friction and heat are produced as a result.

3. Lubrication and Cooling

Use plenty of cutting fluid or coolant to dissipate heat and extend tool life. Coolant also helps to prevent workpiece warping and maintain dimensional accuracy. Coolants formulated with extreme pressure (EP) additives are essential for cutting hard metals. EP additives form a lubricating film between the tool and workpiece, reducing friction and wear. Look for coolants with EP additives like sulfur, chlorine, or phosphorus. Ensure that the coolant is compatible with the specific hard metal you are machining. Some hard metals may have unique requirements, and certain coolants may be better suited to particular materials. Always talk to your lubricant provider to learn about the best coolants, formulations and viscosities for your needs.

4. Rigidity and Stability

Ensure that your lathe setup is rigid and stable to reduce vibration and chatter. This is especially crucial when machining hard materials as they can cause excessive tool wear and poor surface finish when vibrations occur. Slow and shallow cuts on the workpiece will minimize vibration. Measure chatter frequencies related to the machine tool, workpiece and cutting tool characteristics. Finding and avoiding these resonant frequencies helps with chatter avoidance.

5. Monitor Tool Wear

Regularly check the condition of your cutting tools. Hard materials can cause tool wear more quickly than softer ones. Replace or sharpen the tools as needed to maintain consistent performance. Some carbide tooling can be reground to sharpen their edges. Traditional grinding and sharpening methods do not apply due to the inherent hardness of diamond. Some diamond tooling can be reconditioned, replaced with new inserts or resharpened by removing a small

There are some universal strategies when working hard metals on a lathe to get the best parts from the run. Integrating one or a few of the techniques listed above will help produce more consistent parts when cutting extremely hard metals. Contact your LeBlond representative for more details on improving quality or submit your question directly by submitting a request through our online form or call (888) 532-5663 and select option 2.