You’ve heard of tricking out old cars like putting a six-cylinder engine in your ’62 Chevy. Ever thought about tricking out a manual machine tool like a lathe?

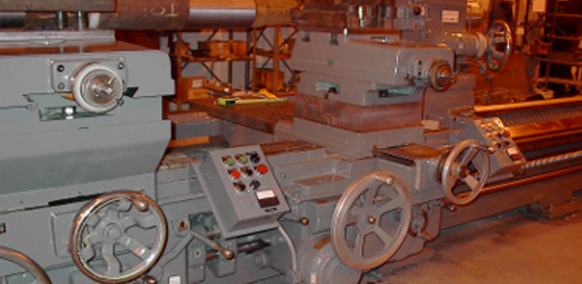

Willenborg Associates can do it. And do it with style. The Michigan company remanufactures LeBlond lathes as well as other OEM’s such as Giddings and Lewis and Cincinnati Milacron.

The advantage of working with Willenborg Associates is that they have a relationship with LeBlond Ltd., a descendant company of the original manufacturer of LeBlond lathes. This means that Willenborg has access to original engineering documentation. Without the original prints, a remanufacturer runs into costly hassles.

“Without [original engineering documentation], one must ‘reverse engineer’ important tolerances, fits, alignments etc.” said Mike Willenborg, President of Willenborg Associates. “It can be done properly without OEM support, but it is extremely hard and time-consuming which means costly!”

For example, in May 2007, Willenborg Associates remanufactured a LeBlond Wide Bed NC lathe into a CNC machine for Iowa-based Precision Pulley & Idler Co., a producer of large pulleys and power transmission equipment for conveyor industries. The first job was so successful, Precision Pulley bought another LeBlond lathe and had Willenborg rework this one.

When Willenborg remanufactures your LeBlond lathe, they do the following:

- Strip the machine completely.

- Replace all bearings, worn gears and shafts as well as motion control screws commonly called ball screws.

- Grind all the guiding ways on the lathe that guide the carriage that holds the cutting tool. Willenborg uses an extremely accurate 100’ long-way grinder for this step.

- Rebuild the gearbox containing the spindle that holds and turns the work piece. Willenborg checks all the components inside the gearbox and replaces anything that is not within new machine tolerance.

- Rebuild the tailstock with “new machine” fits and tolerances.

- Hand-scrape all the sliding members of the machine to fit on the ground guiding ways for proper fits and alignments.

- Completely clean, sand and repaint the equipment.

Willenborg will charge a price range anywhere from $20,000 for small LeBlond lathes to approximately $500,000 for larger, more sophisticated equipment.

In future blog posts, we will detail why LeBlond lathes are perfect candidates for remanufacturing and the cost benefits of this process. Stay tuned!

If you’re interested in a new LeBlond lathe or K.O. Lee machine or interested in original OEM parts for LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, call LeBlond Ltd. at (888) 532-5663.

If you’re interested in contacting Willenborg Associates, you can reach them at (810) 724-5678.