Table of Contents

- The LeBond Regal Lathe Quick History

- The Top 5 LeBlond Regal Parts

- Regal Brake Components: Ensuring Smooth Operation

- Crossfeed Screw Nut: Maintaining Precision

- Crossfeed Screw: Moving the Table

- Headstock Gearing: Smooth Operation for Years to Come

- Pinion: Keeping the Apron Moving

- Contact LeBlond for Regal Parts

- KEY TAKEAWAYS

TL;DR

This blog post highlights the five most in-demand LeBlond Regal parts. We discuss the history of this flagship LeBlond machine and detail the circumstances when you might need to order these replacement parts as well as the support LeBlond’s service department offers when installing them.

The LeBond Regal Lathe Quick History

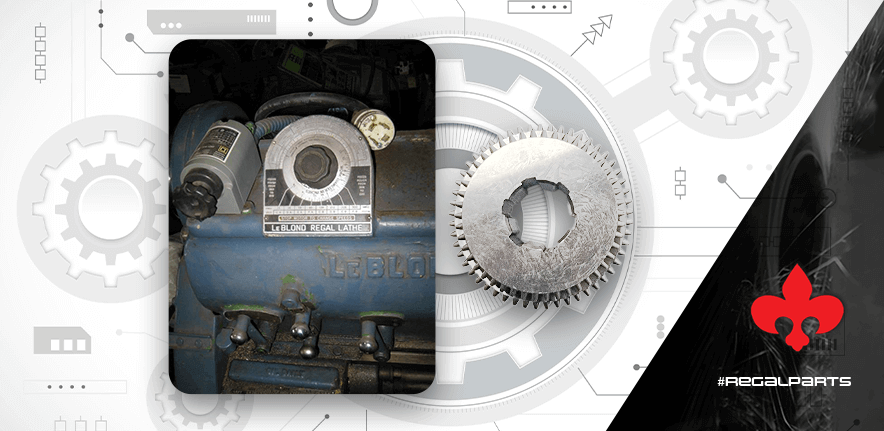

In the 1930s, LeBlond introduced the Regal series of lathes, machines known for their precision and versatility. These manual lathes gained popularity in industrial settings and vocational schools, becoming a staple in machine shops and tool rooms.

While the specific product lineup may have evolved, the LeBlond Regal lathe remains a symbol of quality in the machining industry, making it a sought-after tool for hobbyists and machinists.

The Top 5 LeBlond Regal Parts

If you’re reading this, you undoubtedly are familiar with the LeBlond Regal.

What about OES replacement parts though?

What are the Top 5 most in-demand components to keep your Regal running smoothly?

Let’s explore.

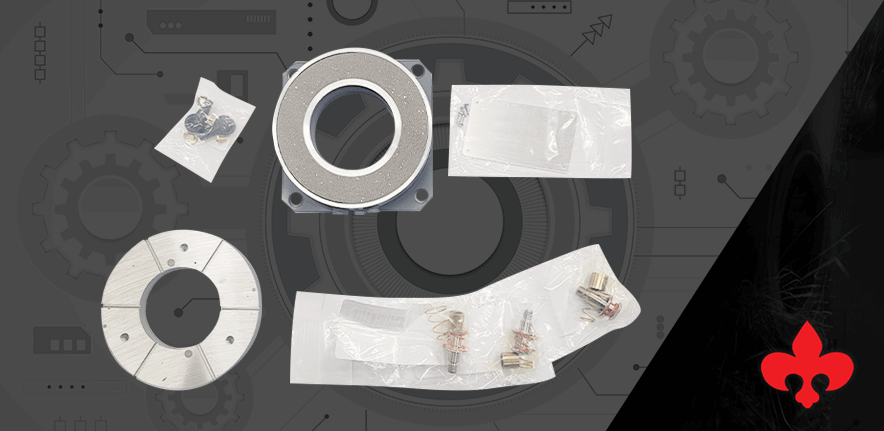

Regal Brake Components: Ensuring Smooth Operation

The brake system on your LeBlond Regal lathe provides a safe and efficient operation. It’s responsible for stopping the spindle when shifting gears or going neutral.

These brakes are electric and slow down and stop the spindle gradually.

Warner brakes are the most common supplier of Regal models and are known for their reliability.

Consider replacing your Regal brakes if you notice any unusual noises or difficulty engaging them.

LeBlond offers over-the-phone service and procedure documents to help you install and troubleshoot brake issues.

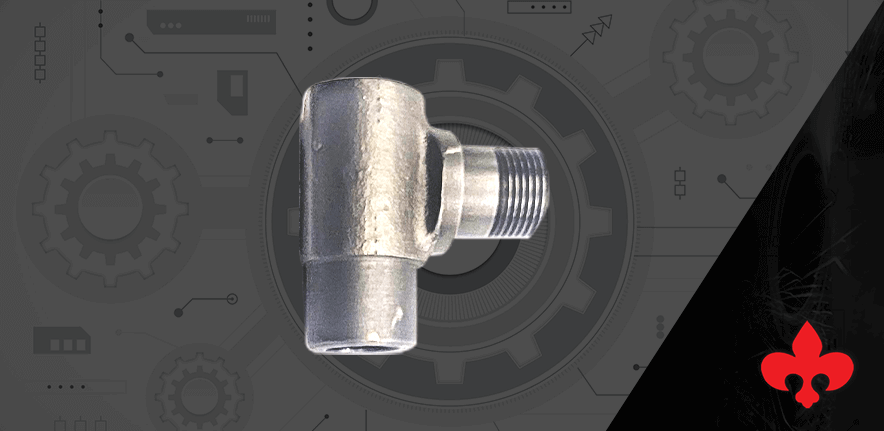

Crossfeed Screw Nut: Maintaining Precision

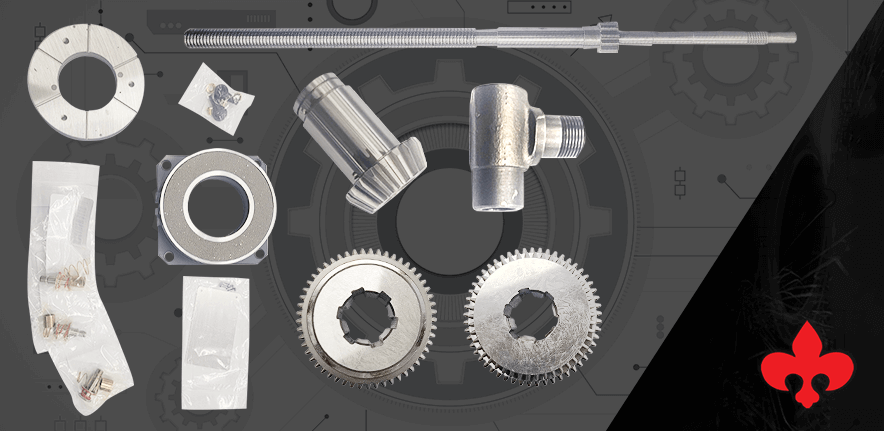

Maintaining precision is a top priority when working with a lathe, and the cross-feed screws and nuts play a vital role in achieving this goal. These components are responsible for moving the cutting tool along the workpiece.

Any play or wear in these parts can lead to errors.

If you suspect issues with these components, such as reduced precision in your cuts or excessive play, it’s time to consider replacements. Procedure documents are available to assist with installation and troubleshooting.

Replacing the cross-feed screws and nuts together is recommended. The crossfeed screw nut is the lower priced component.

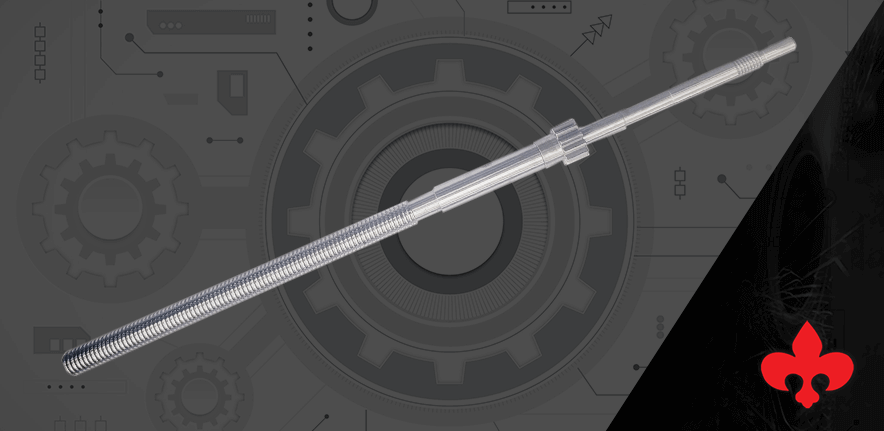

Crossfeed Screw: Moving the Table

The crossfeed screw is a complementary part of the nut and pushes the table in and out of the workpiece.

It is a critical component on a LeBlond Regal lathe and is generally priced higher than the nut. LeBlond typically fits the crossfeed screw nut and screw together before shipping, ensuring compatibility.

Headstock Gearing: Smooth Operation for Years to Come

The headstock of your LeBlond Regal lathe contains various gears that ensure precision during cutting.

These gears have part numbers like 2-17, 19, 21, 4-4 and 4-10. They are crucial for transmitting power from the motor to the spindle, allowing you to achieve the desired speed and torque for your machining tasks.

Issues with headstock gearing can manifest as clunking noises or difficulty in shifting gears. Inspect and replace the affected gears if you experience any of these symptoms.

Fortunately, many of these gears are found across many different Regal lathe models, making replacements readily available.

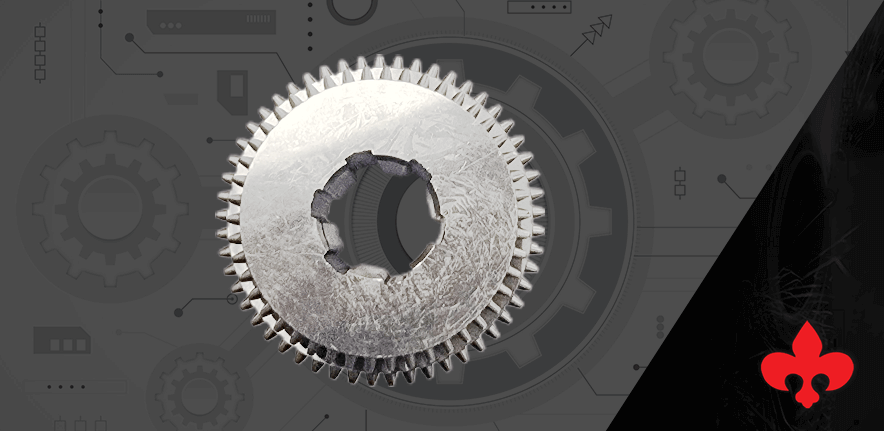

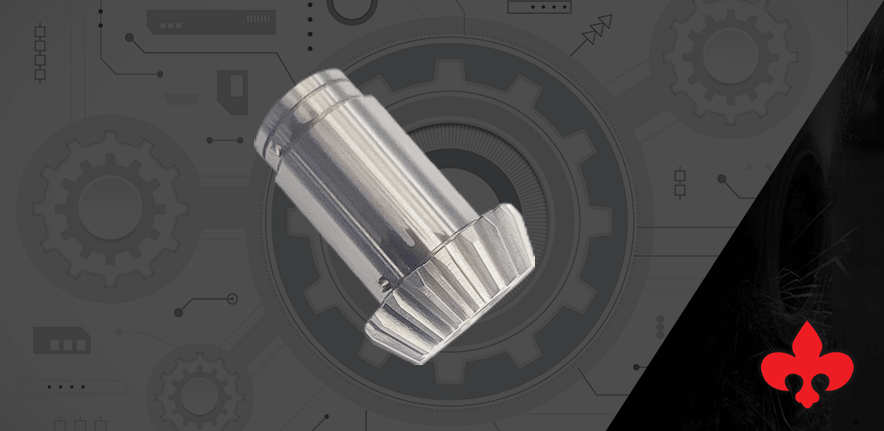

Pinion: Keeping the Apron Moving

The pinion is a toothed component on the Regal lathe apron that drives it up and down the machine.

If your apron is not traversing smoothly, then you might need to call us for replacement parts.

LeBlond offers over-the-phone service to replace these parts, but the procedure is fairly simple. You just need to remove the feed shaft, then insert the pinions.

Contact LeBlond for Regal Parts

LeBlond understands the importance of keeping your Regal lathe up and running.

If you need any of the above replacement parts or ones not listed here, we have the majority of OES Regal parts in stock.

We can get them to you as fast as the next day, minimizing downtime in your machining operations.

Reach out to us if you need replacement parts, guidance on installation or have questions about maintaining your LeBlond Regal lathe:

- Please leave a comment below and we’ll be happy to help.

- Complete the form on THIS PAGE or call us at +1 (888) 532-5663 (Monday-Friday 8am-5pm ET) and select Option 1.

We look forward to hearing from you!

💡KEY TAKEAWAYS

- The iconic LeBlond Regal lathe was introduced in the 1930s.

- Regular maintenance and timely replacement of critical components like brake systems and cross-feed screws and nuts are essential for preserving the precision and safety of your LeBlond Regal lathe.

- Identifying the signs of wear or issues in these components is crucial. If your Regal has unusual noises, increased vibration or sub-optimum performance, contact LeBlond.

I have a 13″ Regal dating back to 1941. Thank you for publishing this information. It’s good to know that there are parts and help available if needed to keep ol’Mr Leblond up and running. For me and my needs it’s a great machine. 🙂

Thanks Joe! Glad the post was helpful for you. Let us know how we can help in the future.