A horizontal band saw is a heavy-duty, industrial machine used for cutting large pieces of different materials into smaller pieces.

This saw is considered an extremely useful tool to make short work of quickly cutting items down to the proper size in woodworking, metalworking and lumbering services.

How Does It Work?

A horizontal band saw is made up of a saw band, a worktable, a power source and two wheels driven by an electric motor at high speed. A workpiece is held stationary in the vice of the band saw while the blade moves vertically down into the piece, using the force of gravity to feed the cut.

Horizontal band saws are not equipped for cutting patterns or intricate curves, but they have excellent precision for straight cuts. They can swivel and make miter cuts. Only straight cuts at a fixed angle can be made on this type of band saw.

Why Blades Matter

When considering blades, metal bandsaw blades have finer and sharper-notched teeth to direct the same force of each stroke into a shallower area of harder materials. The metal’s finer particles will easily fall free of the blade while the lumber particles might not.

TPI (the number of Teeth per Inch) determines the quality of your results. Teeth with greater space in between them allow for better debris removal; teeth with less area in between deliver smoother incisions.

The material and thickness of the workpiece you are cutting will determine the type of blade needed. For example, if you are cutting stainless steel with a thickness of 1”-3” (25-75mm), you would want to use a 6 TPI blade. Bimetal variable pitch blades, such as a 6/10 or 8/12, offer more versatility than standard blades. Blade width should be selected based on the instructions for the particular saw being used.

Horizontal vs. Vertical Band Saw?

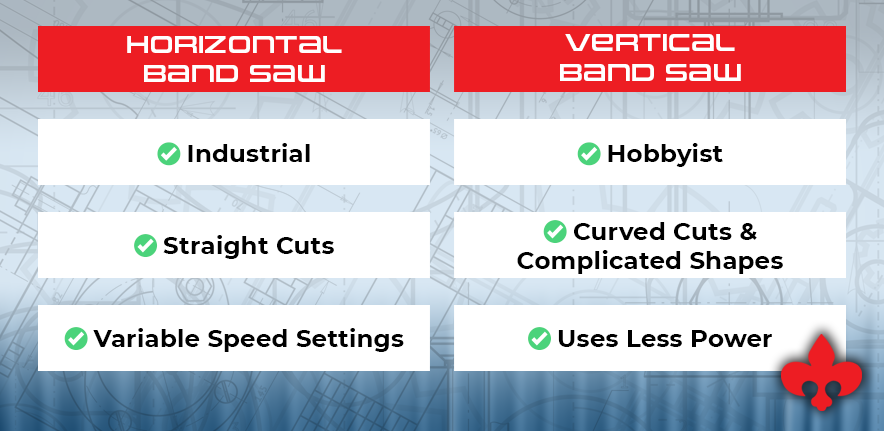

Horizontal band saws like LeBlond’s LHS-10 model are typically seen being used in larger industries like manufacturing. You wouldn’t typically see one in someone’s home or a small shop.

A vertical band saw like LeBlond’s LVs-50 is smaller, requires less power and is capable of curved cuts and complicated shapes.

A horizontal saw cuts anything from plastics, titanium, graphite, soft and even exotic metal. Most modern band saws offer the operator variable speed settings which allow for flexible cutting operations depending on the work matter.

Contact LeBlond for Horizontal Band Saws

If you need a one-stop shop for a band saw and other machine tools, contact us. One supplier for all your equipment facilitates ordering, and your shop floor will have a cohesive, color-coordinated look.

Call us at +1 (888) 532-5663 and select Option 2 or click the button below to get in touch.

We look forward to hearing from you!

i need Vertical bandsaw to cut various profile cuts

Hello Amalraj, thanks for your comment. Someone will get back to you. For immediate service, call us at +1 (888) 532-5663 or email [email protected]