Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

wear parts

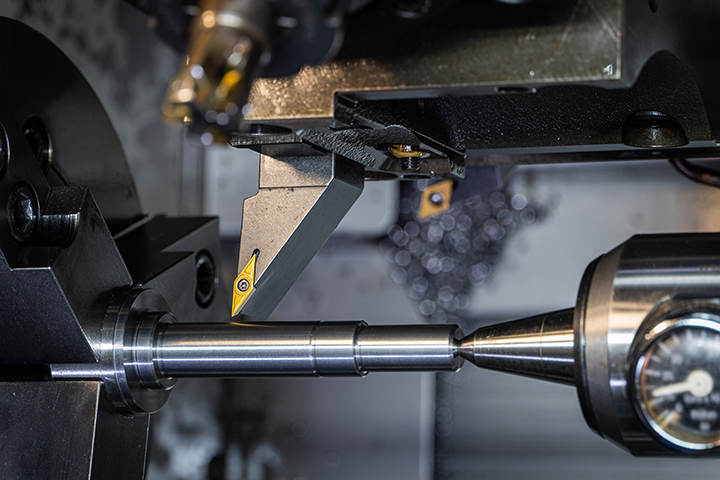

Ten Fixes for Small Part Manufacturing Pain Points

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

Five Lathe Tips for Cutting Extremely Large Parts

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Six Lathe Tips for Cutting Extremely Soft Metals

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

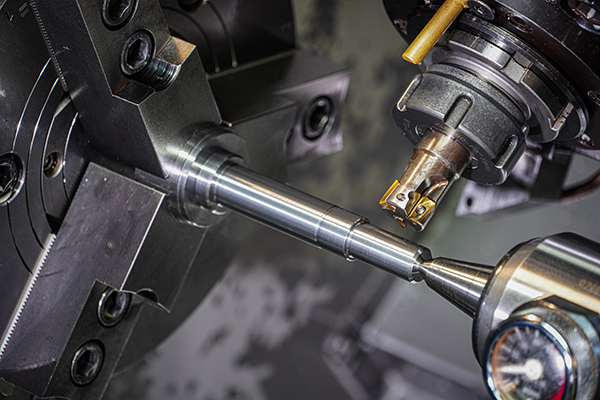

Five Lathe Tips for Cutting Extremely Hard Metals

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Master Six Lathe Tips to Improve Your Output of High-Quality Workpieces

Become a manufacturing super star by following these 6 lathe tips. When put into practice they will greatly improve the final output on finished parts.

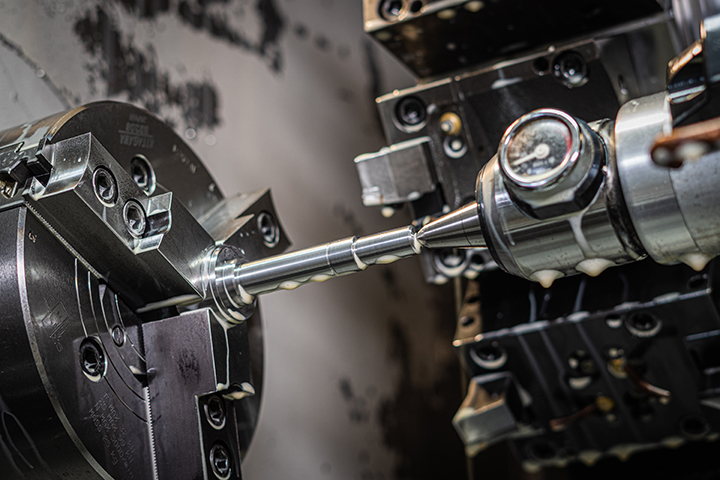

Gang Up Machining Projects for Improved Efficiencies

Implementing batch processing and workpiece consolidation on a lathe involves optimizing your machining processes to efficiently produce multiple parts in a single setup.

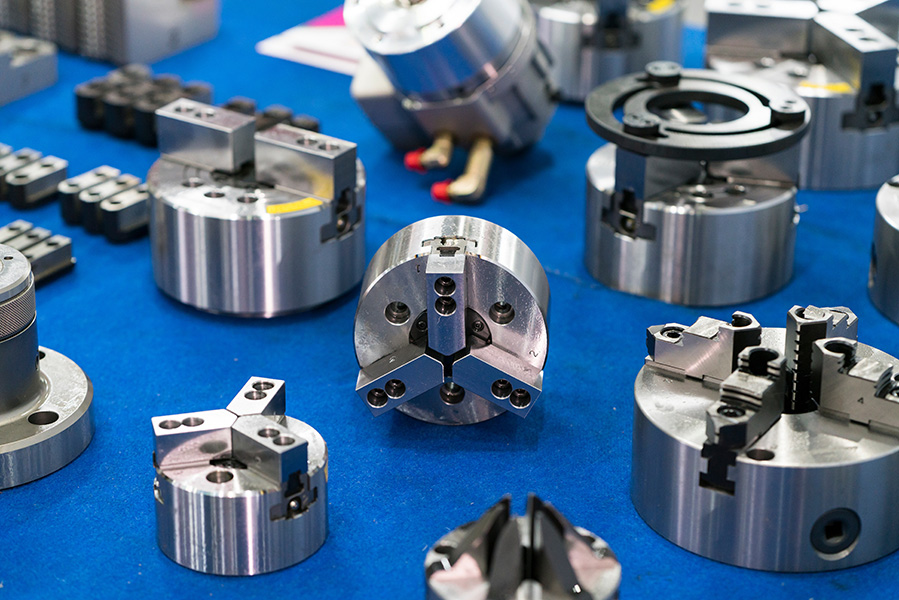

Workholdings are Lathe Workhorses

Workholdings are Lathe Workhorses Accuracy and precision are vital for producing parts with high tolerances in advanced lathe machining. Reliable workholding solutions ensure high-quality and repeatable machining results. Here are five reasons to get workholdings...

Three Tips to Cut Machining Costs

Evaluating Your Practices Can Cut Machining Costs Saving time, improving efficiencies, reducing waste are all ways to cut machining costs and increase margins for machining parts. However, putting the right tactics in place to achieve these cost cutting measures is...