Machining Complex Metal Parts Requires Simple Solutions

Machinists must possess a deep understanding of machining principles, tooling, materials, & machine capabilities to produce complex quality parts. Know these 6 solutions to machining complex part pain points.

Best Solutions for Machinability and Material Selection

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

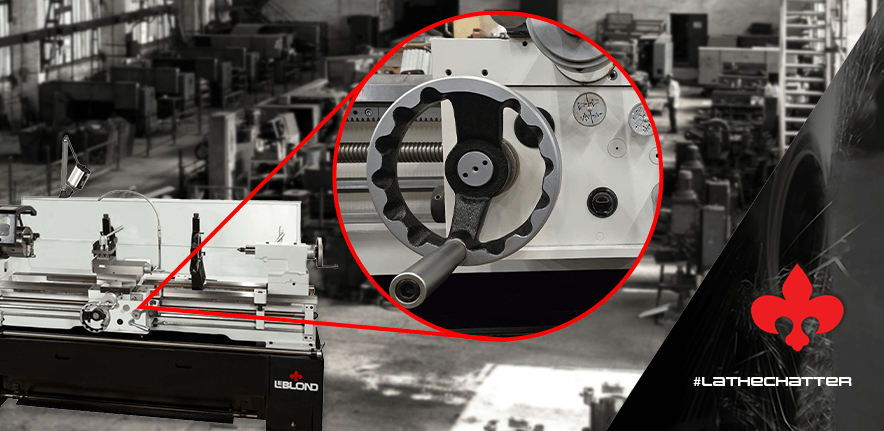

Addressing Lathe Chatter Needs Better GIFs

Dear machinist, the internet doesn’t get you. This is what you get when you type “chatter on a lathe” into an online repository of Graphical Interchange Formats, more popularly known as GIFs: via GIPHY Does the above #chatteringteeth describe your infinite woe when...

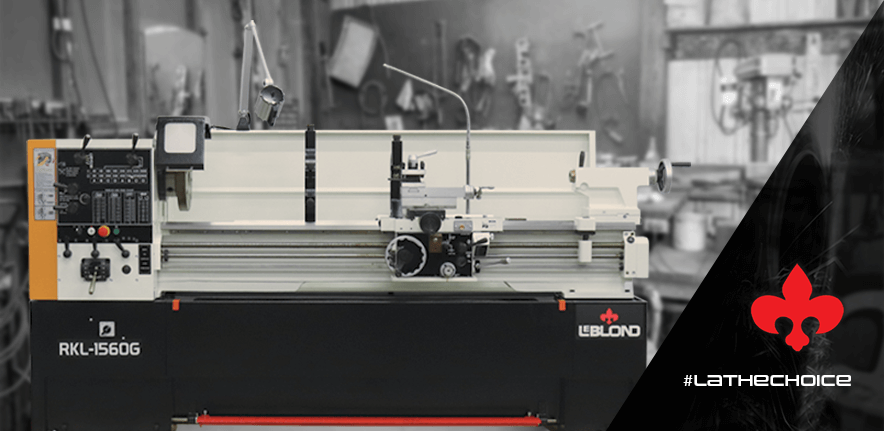

Choosing the Right LeBlond Lathe

Understanding Core Specifications When Choosing a Lathe LeBlond lathes boast a spectrum of features, but three crucial specifications significantly impact the type of work a lathe can handle: Swing over Bed: This refers to the maximum diameter of a workpiece that can...

Top 7 Solutions for Tool Wear and Breakage

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

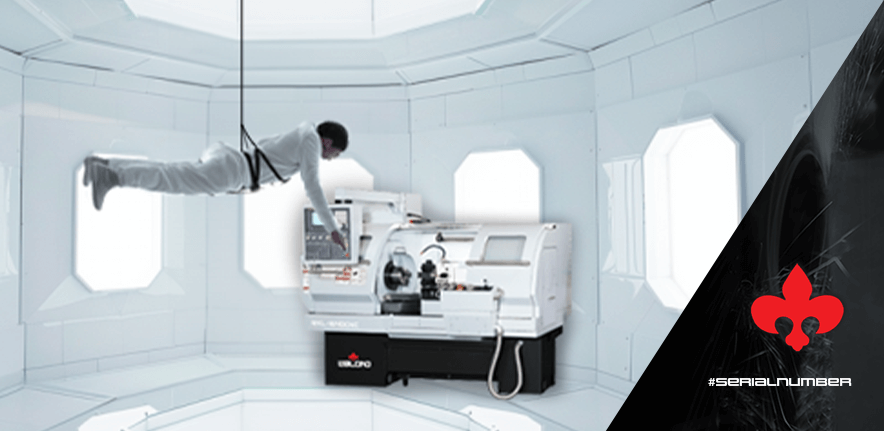

Serial Numbers Make the Mission Possible on LeBlond Machinery

How does a machinist unlock the source code of powerful technology? Like the opening of Mission Impossible 7? https://youtu.be/UsPyNyUwB2M?si=-rcWbFERGPMdndJR A machinist can unlock the power of their equipment by finding the serial number. Uh, I...

15% Off Optional Accessories for LeBlond & K.O. Lee Machinery

A machinist can reduce everything to the tools of the trade — even a bitterly cold football game. Bringing layers of protective, warm clothing could be seen as a machine tool standard accessory if you were attending the coldest football game ever recently hosted by...

Ten Fixes for Small Part Manufacturing Pain Points

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

Five Lathe Tips for Cutting Extremely Large Parts

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

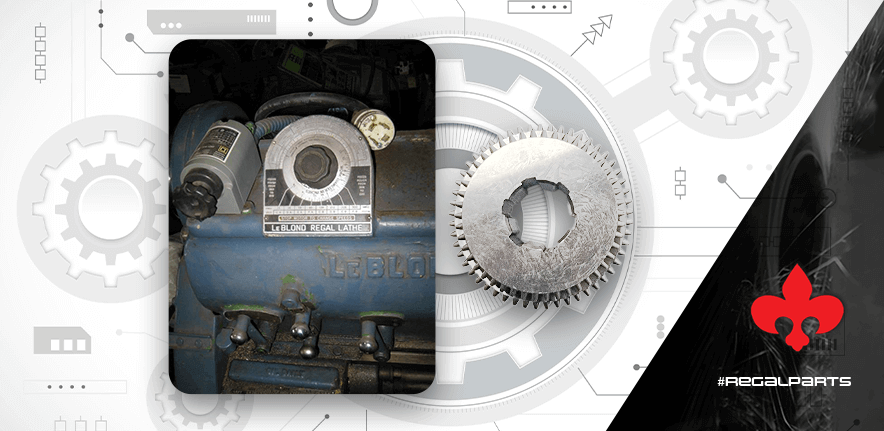

What Are the Top 5 LeBlond Regal Parts?

Table of Contents The LeBond Regal Lathe Quick History The Top 5 LeBlond Regal Parts Regal Brake Components: Ensuring Smooth Operation Crossfeed Screw Nut: Maintaining Precision Crossfeed Screw: Moving the Table Headstock Gearing: Smooth Operation for Years to Come...