Understanding Core Specifications When Choosing a Lathe

LeBlond lathes boast a spectrum of features, but three crucial specifications significantly impact the type of work a lathe can handle:

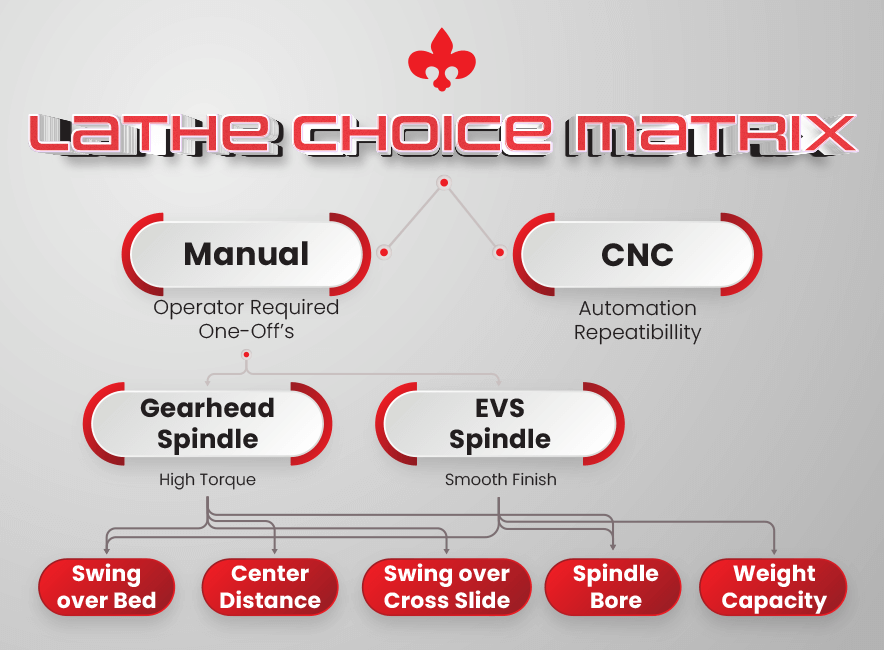

- Swing over Bed: This refers to the maximum diameter of a workpiece that can be rotated over the bedways. Imagine the lathe as a giant set of rotating jaws. The “swing” refers to the largest possible diameter of the object these jaws can hold and spin.

- Distance Between Centers: This dimension indicates the maximum length of a workpiece that can be accommodated between the two pointed centers on the headstock and tailstock. Simply put, it’s the longest solid rod that can be placed between these centers and turned.

- Swing over Cross Slide: This specification designates the maximum diameter of a workpiece you could turn. For example, if you were to use the headstock and tailstock for support, you’re going to be sliding back and forth over the cross slide of your machine up where all the controls are.

Beyond the Basics: Additional Considerations When Selecting the Right Lathe

While the above aspects form the foundation, a successful lathe selection requires further considerations:

- Spindle Bore: This is the opening in the headstock through which the material being turned can pass. If you plan on working with solid rods or bars, the spindle bore diameter needs to be large enough to accommodate them.

- Weight Capacity: Lathes have varying weight capacities. Understanding them is crucial when considering which lathe is best for your shop or classroom. The weight of the workpiece and tooling plays a significant role. When considering the right lathe, we emphasize considering different support configurations for a workpiece:

- Headstock only: This offers the least weight support.

- Headstock and steady rest: A steady rest is an additional rail-like support for the workpiece running along the machine bed. Adding a steady rest increases the weight capacity the lathe can handle.

- Headstock, steady rest and tailstock: Using all three support points provides the maximum weight capacity.

It’s important to remember that weight capacity specifications often assume a specific support configuration. Make sure you understand the weight limitations for your intended use case.

Application Drives Lathe Selection

Choosing the appropriate lathe goes beyond simply matching specifications to a list. LeBlond Sales Engineers assist in the selection process by understanding your intended application — what you need the machine to do.

- Material and workpiece type: The material being turned (metal, wood, etc.) and the complexity of the workpiece geometry significantly influence the required lathe specifications.

- Operations to be performed: Understanding the specific machining operations planned (turning, facing, drilling, etc.) helps determine the necessary features like swing and tooling compatibility.

- Production volume: High-volume production environments like an industrial tool room require a more robust lathe than a hobbyist’s workshop in his or her garage.

By understanding the application, our Sales Engineers can guide you toward the right lathe.

For Example…

We recently spoke to a machinist who was interested in our precision high-speed, heavy-duty 1600 Series.

We spoke to the customer about his specific weight requirement for the workpieces that he had to machine and eventually bumped him up to a 21 Series lathe due to the weight capacity required for his particular application.

Advanced Considerations For Picking a Lathe

These considerations should be at the top of your list when initially deciding to settle on the right lathe.

- Manual vs. CNC Lathe: Do you need to bulk-produce parts with a high degree of repeatability? Then you need a CNC LeBlond operated by OK Computer instead of a manual machine.

- Gearhead vs. Electronic Variable Speed (EVS) Spindle: Do you need a lathe with high torque output suitable for heavy-duty operations, then you will want to consider a lathe with a gearhead spindle. If your machine applications lend themselves to lower torque and workpieces with superior surface finishes due to precise speed control changes, then you would want to consider a lathe with an Electronic Variable Speed (EVS) spindle.

Contact LeBlond Where Selecting the Right Lathe Is Not Complicated

By working with a LeBlond Sales Engineer and considering core specifications (e.g. swing, distance between centers, swing over cross slide, spindle bore) alongside the intended application, we can help guide you through the process that this graphic summarizes:

LeBlond’s commitment to understanding your specific needs ensures that we help you find a machine that matches your requirements.

For assistance, call us at +1 (888) 532-5663 and select Option 2 (Monday – Friday 8am – 5pm ET).

Or just leave a comment here!

We look forward to hearing from you!