Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

News

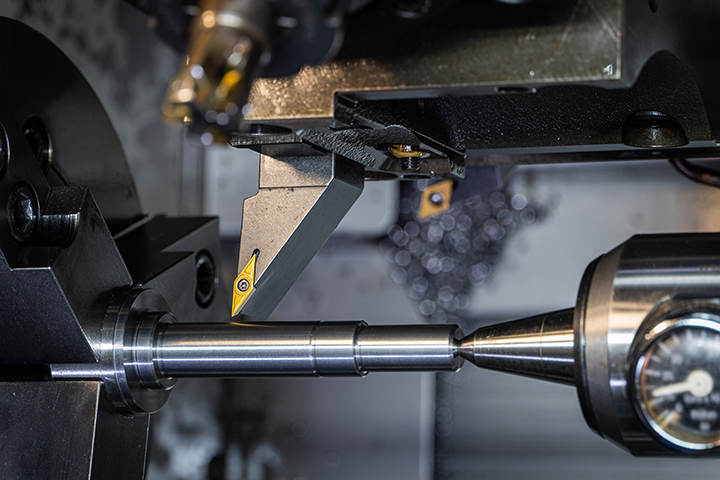

Ten Fixes for Small Part Manufacturing Pain Points

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.

Five Lathe Tips for Cutting Extremely Large Parts

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Six Lathe Tips for Cutting Extremely Soft Metals

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

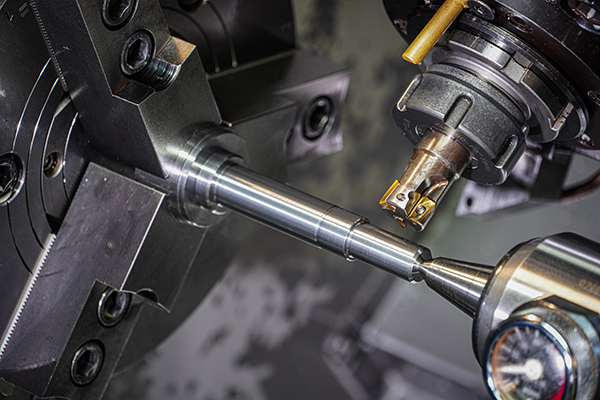

Five Lathe Tips for Cutting Extremely Hard Metals

Become a manufacturing super star by following these 5 hard metal cutting lathe tips. When put into practice they will greatly improve the final output on finished parts.

Get Manufacturing Parts Online with LeBlond’s New Inventory Available Feature

Table of Contents Request for Quote for Manufacturing Parts How Does Our New Industrial Components Tool Work? What Are You Waiting For? Our Machine Components Are OES. Huh!? Need Online Quoting for Machines? We Have You Covered! Get Parts & Reduce Costs with a...

Master Six Lathe Tips to Improve Your Output of High-Quality Workpieces

Become a manufacturing super star by following these 6 lathe tips. When put into practice they will greatly improve the final output on finished parts.

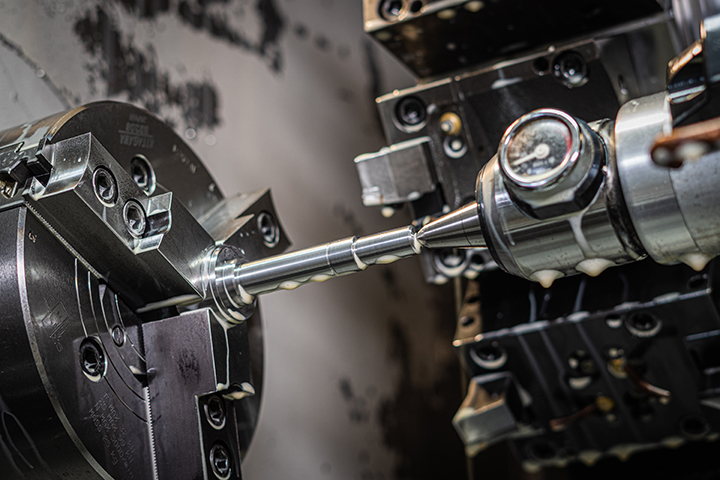

Gang Up Machining Projects for Improved Efficiencies

Implementing batch processing and workpiece consolidation on a lathe involves optimizing your machining processes to efficiently produce multiple parts in a single setup.

Watch Our Internet TV Show & Become Immortal

Need to become an immortal machinist? Por Ejemplo… You crave a deep understanding of ALL machine's tools and equipment. When a foolish superior makes the grave mistake of questioning the accuracy of your workpiece, you will whip out a Coordinate Measuring...