Table of Contents

- But That’s Half the Problem, Right?

- KS34URK; Cylinder Universal Repair Kit

- KB824N: Feed Nut

- KS824-1: Feed Nut Assembly

- KS930F1: Cross Feed Screw

- Machinists Need Fuel!

- KEY TAKEAWAYS

TL;DR

In this blog post, we use a coffee analogy to detail four OES K.O. Lee grinder parts that can be found on LeBlond’s new online Inventory Available tool that allows you to source machine tool replacement parts with convenience and security.

Are machine tool parts like a coffee machine?

Maybe!

Years ago, I bought a Keurig machine with the disposable “K-Cups” that brews a single serving of coffee.

After spending a small fortune on disposable K-Cups, I decided to buy a non-disposable one that you recycle after each use.

You open the lid, clean out the coffee grounds and both help your pocketbook and the environment.

The recycled K-Cup that I bought was cheap and not made to properly fit my Keurig model.

Soon, the recycled K-Cup sprung a leak and I was dabbing bitter coffee grounds from my mouth.

I decided to buy a Universal recycled K-Cup that was of higher quality and made of metal. It was meant to fit ANY Keurig coffee maker.

Problem solved.

No coffee grounds in my mouth, and I am not adding to a landfill or having a 200-ton ballast attached to my wallet.

If you have a new or vintage K.O. Lee grinder, we encourage you to shop for quality Original Equipment Supplier (OES) parts that are manufactured to meet the exact specifications of the machine like my recycled K-Cup.

But That’s Half the Problem, Right?

Where do you find replacement parts for K.O. Lee grinders with the convenience of online shopping?

LeBlond has a solution with our Inventory Available tool where you can source K.O. Lee replacement parts but with the added security of not having to worry about your credit card floating around the dodgy internet.

LeBlond will soon add K.O. Lee parts to the Inventory Available feature that already features OES LeBlond, Standard Modern, Johnson Press and Deka Drill parts.

To whet your appetite, we review four K.O. Lee parts below soon to be featured on our new tool.

We cover their features, benefits and even maintenance tips, so you can keep your K.O. Lee machinery humming along nicely for years to come.

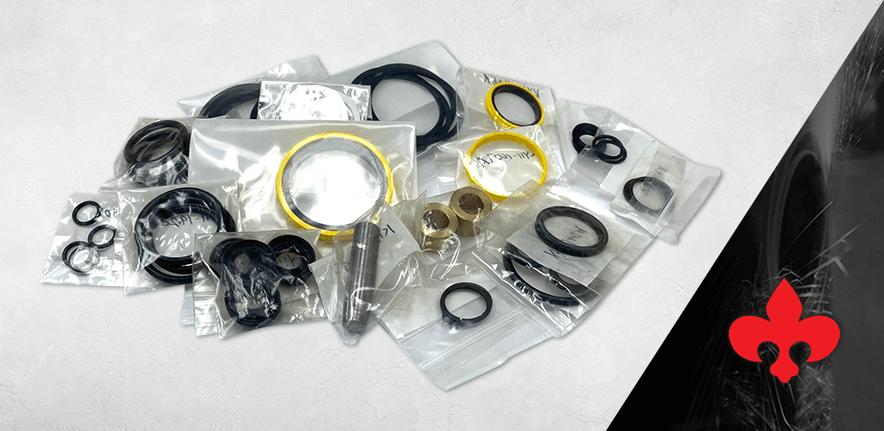

KS34URK: Cylinder Universal Repair Kit

- Purpose:

- The universal repair kit is used to repair the cylinders for K.O. Lee machines.

- These cylinders play an essential role in the hydraulic system of these machines.

- Function:

- The cylinders, being a part of the hydraulic system, move the table of the machine in various directions (i.e. left-right, back-forth).

- The movement is powered by hydraulic oil pumped through the cylinder, expanding or retracting it.

- Failure:

- The seals inside these cylinders can wear out and start leaking over time.

- The universal repair kit provides the necessary parts to fix this wear and tear.

- Versatility:

- This repair kit is universal, meaning it can be used on all hydraulic K.O. Lee machines. Whether it’s a surface grinder or a tool and cutter grinder, if the machine is hydraulic, this kit is compatible.

- Contents:

- The kit contains a variety of seals – as many as 30 different types.

- These seals are meant for repairing all the cylinders on a K.O. Lee hydraulic machine.

- Frequency of Replacement:

- Depending on usage, a cylinder may require rebuilding every decade.

- The more frequently the hydraulic system is used with new seals, the longer those seals will last.

- Conversely, if the machine is not used regularly, the seals are more likely to dry out and leak.

- Popularity:

- In moderate demand, with about one kit being sold every month.

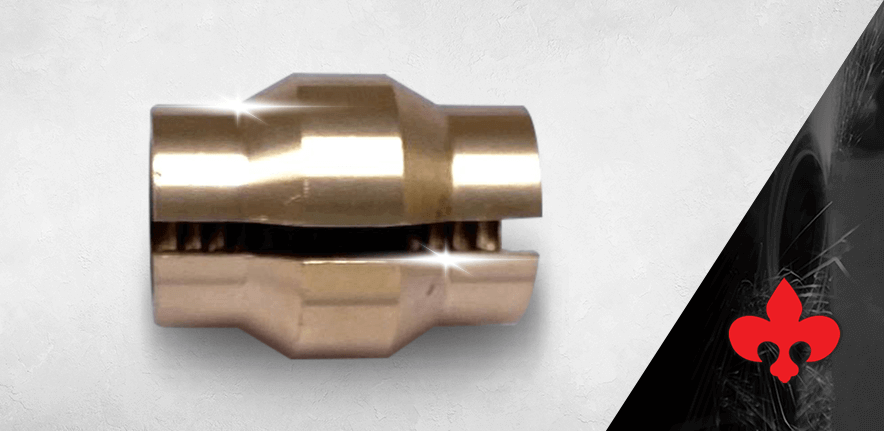

KB824N: Feed Nut

- Purpose:

- Controls the table feed mechanism.

- Designed to control the fingertip action.

- Ensures the feed screw stays straight and manages its movements.

- Location & Compatibility:

- Located on the machine table.

- Governs the X-axis (left and right) movement of the table.

- Suitable for both surface grinders and tool and cutter grinders.

- Material & Durability:

- Made of brass.

- Longevity varies based on usage; more frequent use leads to quicker wear.

- Potential lifespan ranges from a few years to the machine’s overall lifespan (i.e. 30 years).

- Machines operating 8-10 hours daily might need replacement every couple of years.

- Maintenance:

- Requires lubrication.

- Some newer machines offer self-lubrication, while others need manual lubrication.

- Oiling is recommended daily as preventive maintenance for machines without self-lubrication.

- Accessible from the back of the machine

- For machines without built-in oilers, manual lubrication is recommended before each use.

KS824-1: Feed Nut Assembly

- Definition:

- A type of feed nut similar in function to the previously discussed feed nut (part ID KB824N).

- Differentiates in style.

- Function & Compatibility:

- Controls the X-axis movement (left and right) of the table.

- Compatible with certain types of screws.

- Material & Design:

- Made of brass.

- Chosen to be softer than the steel screw it accommodates.

- Designed to wear out before the more expensive steel screw does, providing cost savings over time.

- Contains adjustment bolts to adjust its tightness, extending its lifespan.

- Supply & Availability:

- Typically held in limited stock.

- If out of stock, it can be reordered with a lead time of 30 to 45 days.

- A common practice for LeBlond is to reorder in multiples based on annual sales data.

- Maintenance:

- Designed for hydraulic mechanisms, so it might have self-lubrication features.

- Unlike some feed nuts, this one might not require daily manual oiling due to its self-lubricating design.

- Sales & Popularity:

- Quoted five times and sold twice so far in 2023

- Appears to have a longer wear time compared to some other feed nuts due to its adjustability.

KS930SF1: Cross Feed Screw

- Definition & Function:

- A screw that controls the X-axis movement (left and right) of the machine table.

- The nut attaches to this screw to facilitate the table’s movement.

- Signs of Required Replacement:

- If the table stops moving.

- If there’s noticeable backlash in the handle when moving the table left or right.

- Material & Durability:

- Made of steel, which is a strong metal.

- Typically requires replacement approximately every six years.

- Maintenance:

- Maintenance requirements are contingent on the machine’s age and model.

- Newer machines may automatically oil the screw.

- Older machines require manual oiling, typically daily.

- Popularity & Demand:

- Among the most popular parts sold by LeBlond.

- Variability exists in demand for grinder parts, but cross feed screws are consistently sought after.

Machinists Need Fuel!

We make the coffee analogy because we know our target market.

Machinists love feeds, speeds and Java beans!

If you want a replaceable K-Cup for a Keurig coffee maker or an OES K.O. Lee replacement part that is high quality and meant to fit the exact requirements of your machine, check out LeBlond’s Inventory Available online tool:

- If you have any specific questions on our new tool or OES K.O. Lee parts in general, please leave a comment and we’ll be happy to help.

- Prefer a phone call? Reach out to us at (888) 532-5663 and select Option 1.

We look forward to hearing from you!

💡KEY TAKEAWAYS

- This blog draws a parallel between the quality of Keurig coffee machine parts and K.O. Lee grinder parts, emphasizing the importance of Original Equipment Supplier (OES) parts that are high quality and manufactured from the original machine prints.

- LeBlond has an Inventory Available online tool, providing a secure platform to source replacement parts for K.O. Lee grinders and other machines.

- We detail four specific K.O. Lee grinder parts where we list their functions, maintenance and benefits.