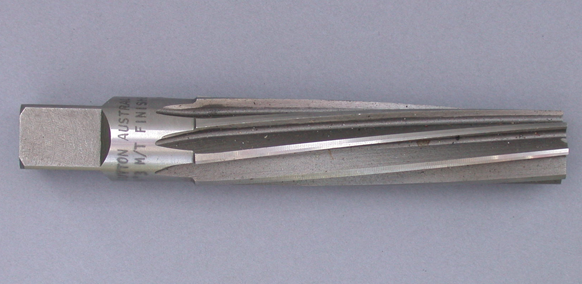

A reamer is a cutting tool used to enlarge the diameter of an already existing hole. Reamers produce a smooth finish while cutting to size. You can use K.O. Lee Universal Tool & Cutter grinders to sharpen a reamer.

Different types of reamers exist including hand reamers, straight-shanked and taper- shanked machine or chucking reamers, adjustable or expansion reamers, inserted tooth reamers and shell ones.

Check out the following video on the use and care of reamers that can be sharpened with K.O. Lee Universal Tool & Cutter grinders:

Don’t pay attention to the video at the 4:10 mark! Reamers can be sharpened, as mentioned, on K.O. Lee Universal Tool & Cutter grinders. With the exception of grinding the chamfer or leading taper, all solid reamers are reduced in size when their blades are ground on the periphery.

With these reamers, when the peripheral cutting land has become dull at the cutting edge, a cup wheel is used and the reamer is reduced to the next smaller size. Since most dullness occurs at the lead cutting edges, most sharpening consists of grinding only the chamfer or lead taper. Refer to this Practical Machinist forum post on tips for sharpening your reamers.

If you’re interested in new K.O. Lee grinders, call LeBlond Ltd. at (888) 532-5663 Ext. 202. If you’re interested in new LeBlond manual lathes or need original OEM parts for LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, call (888) 532-5663.