What do you put in a machinist’s stocking this holiday season?

We at LeBlond don’t advise stuffing the Christmas stocking with small gifts or candy.

Put a chuck for a K.O. Lee grinder in the stocking instead!

And what specific chuck do you need for surface grinding, a precision machining process that requires reliable workpiece holding?

The chuck you choose can significantly impact your grinding efficiency, precision and overall machining experience.

This post details three different types of common surface grinder chucks and how to select the best one for your machine shop or classroom.

Understanding Surface Grinder Chucks

A surface grinder chuck is more than just an accessory—it’s a critical component that holds your workpiece securely during the grinding process.

Just like a three-jaw chuck on a lathe, a surface grinder chuck ensures your workpiece remains stable and precisely positioned throughout the machining operation.

Three Chuck Options: Permanent Magnetic, Electromagnetic & Fine Pole

Let’s detail these grinder workholding options.

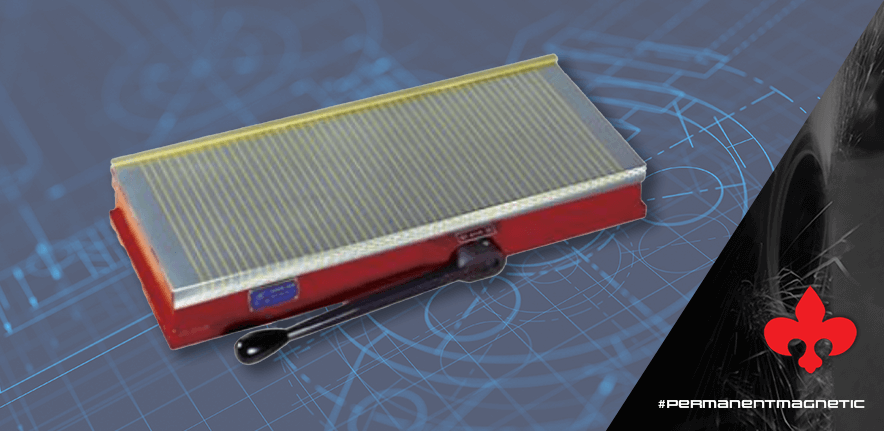

Permanent Magnetic Chuck: Simplicity & Cost-Effectiveness

The permanent magnetic chuck offers a straightforward, budget-friendly solution for surface grinding.

This chuck doesn’t require any electrical hookup, making it an attractive option for smaller surface grinders like our KOL-618 model with a 6” x 18” (152.4 x 457.2mm) table.

Key features of the permanent magnetic chuck include:

– Mechanical lever activation for magnetizing

– No electrical requirements

– No heat generation

– Lower cost compared to electromagnetic options

Operation is simple: a lever engages and disengages the magnetic hold. Once activated, the chuck provides a reliable grip on your metal workpiece without any additional power input.

Electromagnetic Chuck: Versatility & Easy Workpiece Handling

Electromagnetic chucks bring a more dynamic approach to workpiece holding.

These chucks use electrical current to generate a magnetic field, providing a flexible and easily adjustable clamping solution.

Standout characteristics of electromagnetic chucks include:

– Switch-controlled magnetization

– Ability to vary magnetic force

– Quick workpiece removal

– Requires an auto-demagnetizer for operation

The electromagnetic chuck allows machinists to quickly add and remove workpieces with a simple switch. However, it comes with considerations like electrical dependency and potential power fluctuation risks.

Fine Pole Chuck: Precision for Smaller Workpieces

Fine pole chucks are a specialized solution designed for holding smaller workpieces with exceptional precision.

The key difference lies in the magnet configuration—magnets are positioned closer together, enabling secure gripping of smaller components.

Benefits of fine pole chucks:

– Optimized for smaller workpiece holding

– Closer magnet positioning

– Enhanced grip on compact parts

What Surface Grinder Chuck Is Best for Me?

When selecting a chuck, consider your specific machining requirements.

For our smaller surface grinders like the KOL-618, you have the flexibility to choose between permanent magnetic, electromagnetic and fine pole chucks.

As surface grinder size increases, your options become more limited. Larger machines like our KOL-1020HS model exclusively offer electromagnetic chucks.

This progression reflects the increasing complexity and power requirements of larger grinding equipment.

Cost & Practicality

Permanent magnetic chucks typically represent the most cost-effective option. Electromagnetic chucks not only have a higher initial cost but also require an additional auto-demagnetizer, further increasing the investment.

Most machine shops will select one chuck type that best suits their primary workpiece requirements. It’s uncommon to switch between chuck types frequently, so choose wisely based on your most common machining tasks.

Contact LeBlond for K.O. Lee Surface Grinder Accessories

So we have three chuck options for machinist stocking stuffers, especially good ones if the machinist in your life is into surface grinding.

You just might need a slightly larger stocking to hang over the fireplace!

Whether you prioritize cost-effectiveness, workpiece versatility or precision for smaller components, there’s a chuck solution designed to enhance your surface grinding performance.

Interested in a K.O. surface grinder, a chuck or other accessories?

- Call +1 (888) 532-5663 (Monday – Friday 8am-5pm ET) and select Option 2.

- Or visit THIS PAGE to review our lineup of manual and automatic K.O. Lee grinders where you can explore different models and popular accessories.

- Or leave a comment below!

We look forward to hearing from you!