5 Tips for Upgrading Lathes

LeBlond lathes have stood the test of time for many machine shops and parts manufacturers. It isn’t unusual to see a LeBlond lathe from the 1940s still running strong. And as long as those machines are well maintained, they can last for generations. Those well-used machines can still produce great parts and serve their role, but there are a few signs to tell you when it is time to upgrade your lathe.

Automated Digital Setup

When there are multiple different setups for a single part, it may be more time consuming to reconfigure the settings for each step in the process. Automation for parts setup can be stored by some newer machines for future use. Electronic PLCs built into newer machines reduce the setup for complex and repeatable parts.

Expanding Operations

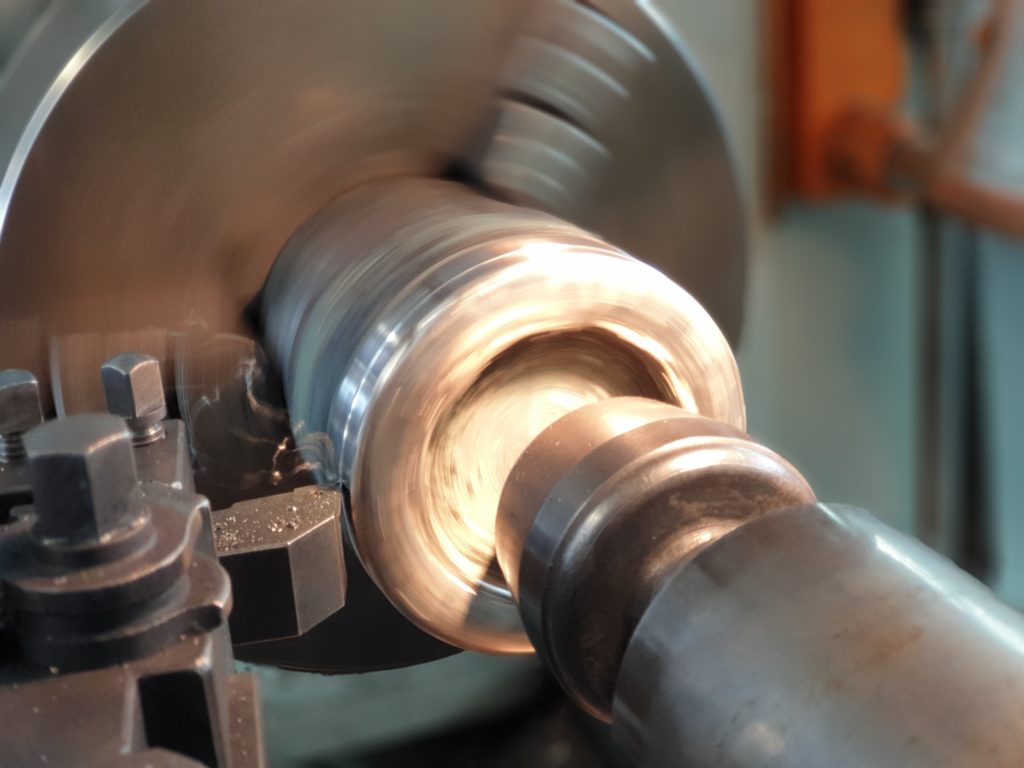

Of course, as a machine shop grows, the need for additional machines comes with the expansion. But expansion can also come in the form of the breadth and depth of parts manufacturing. By adding machines with larger headstock spindles, more powerful motors, more distance between center and wider swing, a broader range of complex parts can be produced. Additionally, it may be time to upgrade if the parts requested by the client are larger than the current machine can handle – both in volume and physical size.

The need for more precise parts

For some companies, high tolerances are vital for their manufactured parts. The right machines to handle these precisely specified cuts add value to the final output. Some high-precision machines make all the difference in the finished part. Upgraded machines can perform more complicated cuts faster.

Jobs take longer to complete

Without proper maintenance schedules and tune-ups, the less efficient your lathe becomes. You may find that “minor” inefficiencies like loss of correct amounts of lubrication or faulty circuitry can lead to increases in the time it takes to complete an order. You find lead times are longer for the same jobs. A series of small delays caused by older machine inefficiencies can add up to bigger delays. Readjusting these inefficiencies and time-consuming lathe releveling could be a tell-tale sign the lathe needs an upgrade.

Malfunctions are more frequent

Issues begin to pile up for both the machine and the parts it produces when wear and tear takes a toll on a machine. During your quality assurance testing, there is more scrap due to looser tolerances. Your machinists’ adjustments no longer match the machine settings. There is some educated guessing that happens before landing on the appropriate settings. Part quality suffers when trial and error is part of the process. More scrapped parts mean lower margins for your projects. This is especially true if you are machining expensive metals or alloys.

If any of these signs sound familiar to you, then your machine shop should consider upgrading to newer machines. Lathes are the workhorses of a machine shop because their versatility and durability. Learn more about how a more efficient machine can save you money in the long run.

For more details about what you need to upgrade your lathe, contact your LeBlond Ltd. representative.