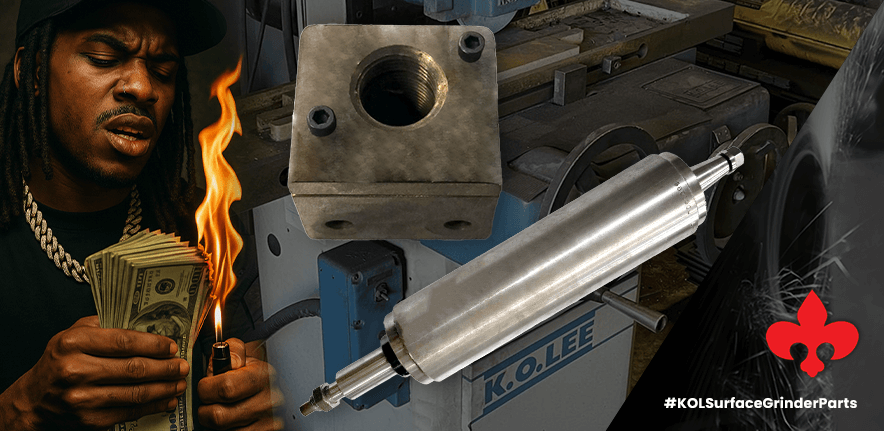

That’s what happens when you ignore maintenance until it’s too late.

You have to buy new equipment in the neighborhood of five figures. I dunno — maybe you should just burn stacks of money instead.

LeBlond Service Manager Christopher Smith has seen it countless times. Shop owners who think their K.O. Lee surface grinder will run forever without proper care. Then reality hits like a sledgehammer.

“The threads just wear out over time and widen,” Smith explains about crossfeed screws. “You can start getting a lot of backlash.”

That backlash isn’t just annoying. It’s destroying your precision work and eating your profits.

The $4,200 Wake-Up Call

Background Image via Jeff Slade

Let’s talk about your spindle. This isn’t some throwaway part you grab from the bargain bin.

A K.O. Lee surface grinder spindle replacement runs $1,800 to $4,200. That’s assuming yours can even be rebuilt.

Smith checks every spindle for runout during rebuilds. If your spindle has more than three-thousandths runout, it’s toast. “You’ll start seeing uneven wear on your grinding wheel, which is ultimately going to affect the flatness of what you’re grinding.”

Translation: Your parts won’t meet tolerance. Your customers will find new suppliers.

Temperature: The Silent Killer

Here’s something most operators never think about. Your spindle is running too hot.

“We don’t want to see it get over 108 degrees,” Smith warns. Most shops have no idea what temperature their machines are running.

Grab a temperature laser from Home Depot for $40. Check your spindle regularly. If it’s too hot to touch, something’s wrong with your bearings.

Once those high-speed precision bearings start failing, you’re looking at distorted spindle geometry. That’s when a simple bearing replacement becomes a complete spindle rebuild.

Oil Daily or Pay Later

Every surface grinder conversation comes back to the same thing. Lubrication.

“It should be daily or whenever you’re using the machine,” Smith says about oiling schedules. Not weekly. Daily.

Your K.O. Lee has either automatic pumps or manual hand pumps. Use them. Those high-speed bearings spinning at 4,500 to 6,500 RPM generate serious heat. Without proper lubrication, the oil and grease start breaking down.

That’s when grinding dust gets underneath your seals. Then it reaches your bearings. Then you’re buying new parts.

The Crossfeed System Nobody Talks About

Your crossfeed screw and nut work together to move your table on the Y-axis. The nut is made of brass for a reason.

“It’s designed to help keep the crossfeed screw to live a longer life,” Smith explains. Brass-to-steel contact creates smoother movement than steel-to-steel.

But brass is softer. It wears faster. That’s the trade-off for protecting your more expensive crossfeed screw.

Keep both components clean and lubricated. Replace the brass nut before it develops excessive play. It’s cheaper than replacing the entire crossfeed assembly.

Seals: Your First Line of Defense

Those little rubber seals around your quill? They’re protecting thousands of dollars in precision components.

High-speed quill nut seals break down from heat and contamination. Smith replaces them during every spindle rebuild, no questions asked.

If the machine’s being run every day for an eight-hour shift, you’re probably looking at yearly replacement.

Check your end caps monthly. They’re like dust covers on your quill. If you see dirt or damage, it’s time for maintenance.

The Wheel Guard Reality Check

Your wheel guard looks like safety theater. It’s actually protecting your investment.

Most shops that follow safety regulations require guards. If you buy a used grinder missing its guard, you’ll need to source a replacement.

Clean it monthly. Grinding dust builds up fast. Use a putty knife to scrape out accumulated debris.

Handle Wheels: Simple but Critical

Those handle wheels controlling your table movement seem bulletproof. They’re not.

The keyway can get wallowed out from wear. The slot in the center that accepts the key starts getting sloppy.

Or some forklift operator backs into your machine and snaps the handle. Know your surroundings. Train your people properly.

Timing Belt Pulleys for Automated Systems

If you’re running automatic crossfeed, your timing belt pulley moves the table through a servomotor.

The keyway can get sloppy from torque if you’re not maintaining proper lubrication on your bedways. Keep those ways clean and oiled.

The Complete Quill Assembly Solution

Smith offers a complete quill assembly as a spare. Think of it like having a spare transmission.

“It’s almost like changing a tire,” he says. “You can have a complete spare on the shelf and swap it out while the other one’s being repaired.”

Zero downtime while your original gets rebuilt. That’s how smart shops operate.

Contact LeBlond for K.O. Lee Surface Grinder Parts

Stop treating your K.O. Lee like it’s indestructible. Start treating it like the precision instrument it is.

Check temperatures with a $40 laser thermometer. Oil daily. Inspect seals monthly. Keep everything clean.

New K.O. Lee grinders come with maintenance checklists on the machine tower. Older machines don’t. Create your own checklist. Follow it religiously.

The alternative is watching a $4,200 spindle replacement eat your quarterly profits.

Your choice.

If you need Original Equipment Supplier parts for a vintage K.O. Lee Surface Grinder, please get in touch.

- Find online parts ON THIS PAGE.

- Call +1 (888) 532-5663 (Monday-Friday 8am- 4:30pm ET) & select Option 1.

- Or leave a comment below!

We look forward to hearing from you!

(Banner background machine image via MR METAL FAB LLC)