What Are the Best Uses of Metalworking Lathes?

Versatile Cutting Creates Opportunities for a Broad Range of Machined Parts

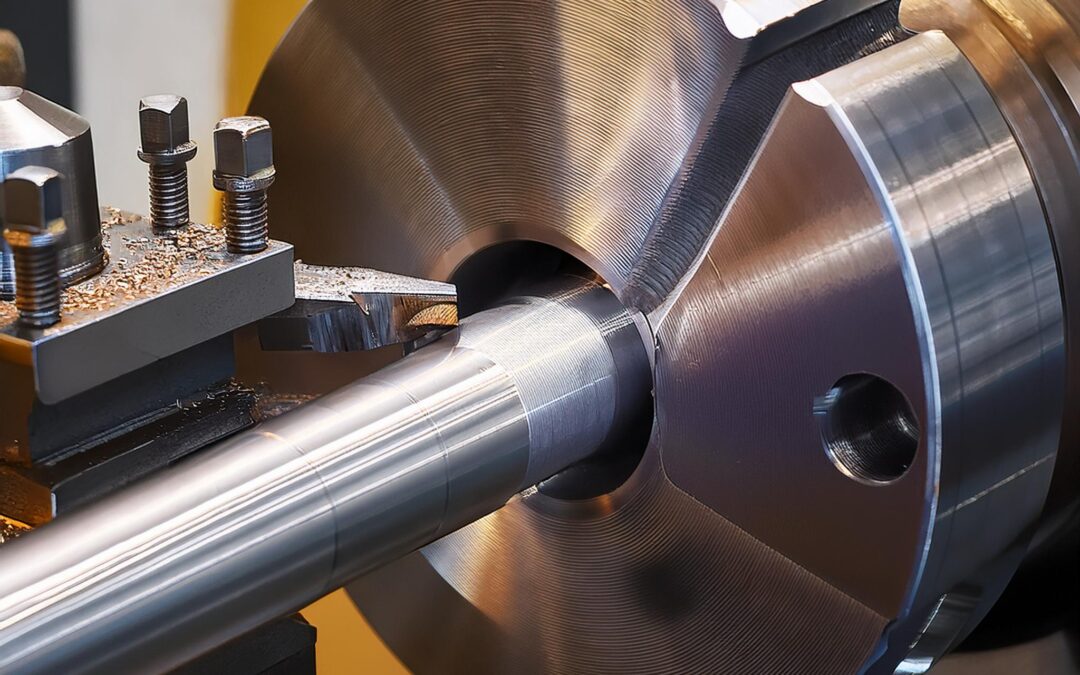

Metalworking lathes are versatile machines used primarily for shaping metal and other solid materials. They are essential in various industries for machining parts using techniques such as:

1. Turning:

This is the primary function of a lathe, where the workpiece is rotated against a cutting tool to remove material and create cylindrical shapes like shafts, rods, and bushings. Turning is used to produce components like shafts, rods, cylinders, and other symmetrical parts. It can be used for both roughing (removing large amounts of material quickly) and finishing (achieving precise dimensions and smooth surface finish).

2. Facing:

Lathes can be used to create a smooth flat surface at the end of a workpiece, ensuring it is perpendicular to the axis of rotation. Facing is crucial for ensuring parts fit together accurately, such as in assemblies where components need precise mating surfaces. It also improves the appearance and functionality of parts.

3. Drilling:

Many lathes have attachments or capabilities to drill holes accurately into the workpiece. Drilling on a lathe is used to create holes that are concentric with the rotational axis of the workpiece. This is essential for components that require precise alignment of holes, such as for bolts, pins, manifolds, and various mechanical assemblies.

4. Knurling:

This process creates a textured pattern on the surface of a workpiece, often used for improving grip or aesthetic purposes. Knurling creates a pattern of straight, angled, or diamond-shaped lines either rolled or pressed into the surface of a workpiece.

5. Parting:

Lathes can cut off sections of a workpiece to create separate parts. Parting tools also create narrow slots or grooves in a workpiece. This is useful for applications such as creating keyways, decorative patterns, or channels for other components.

6. Taper turning:

Creating tapered surfaces, which are common in components like cones or certain types of screws. This activity involves machining a gradual reduction or increase in diameter along the length of a cylindrical workpiece. It allows for the production of parts that fit precisely into mating components or fulfill specific functional requirements.

7. Thread Cutting:

Lathes can cut threads on cylindrical parts, essential for creating screws, bolts, nuts, and fasteners. Thread cutting on a lathe ensures precise thread profiles and pitch, which are critical for proper assembly and functionality of threaded components.

Metalworking lathes come in various sizes and configurations, from small benchtop models for hobbyists and small-scale production to large, heavy-duty machines used in industrial settings. They are critical tools in manufacturing and repair operations across industries such as aerospace, automotive, electronics, and general machining.