Keeping your vintage Regal lathe running smoothly requires understanding its unique features. One such feature is the servo shift system, known for its smooth and precise gear changes. However, when the servo shift brake malfunctions within this system, gear changes become sluggish or stall altogether.

In this blog post, we talk about servo shift brakes, rectifier function and how to diagnose common issues to get your lathe back in top gear.

What are the Components of a Servo Shift System?

The servo shift system relies on a coordinated effort between several components:

- Micro Switch: Activates when you turn the knob to change gears, this switch initiates the gear shift sequence.

- Zero Speed Switch (ZVM): Acts as the control center, the ZVM receives the signal from the micro switch. However, it waits for a vital confirmation before initiating the shift.

- Brake: This crucial component brings the lathe spindle to a complete stop before the gear shift occurs.

- Servo Shift Unit: This unit controls the actual gear change mechanism based on signals from the ZVM.

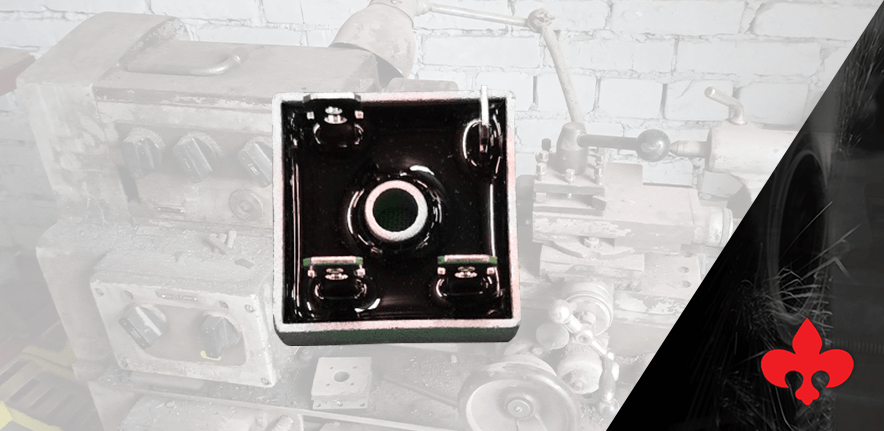

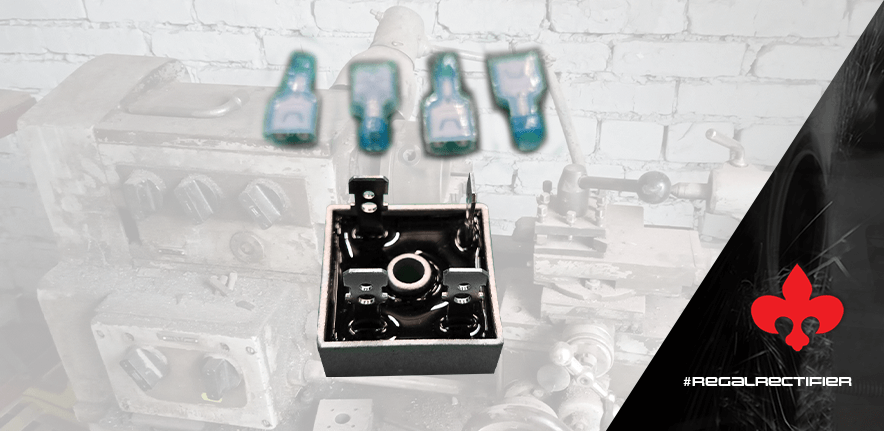

The Rectifier

The rectifier is a key component in the Servo Shift System. It acts like a translator, converting the lathe’s incoming Alternating Current (AC) voltage into Direct Current (DC) voltage.

This DC voltage is then supplied to the brake. The amount of DC voltage determines the brake’s stopping power.

Signs of a Failing Rectifier

If your lathe’s gear changes are experiencing issues, a failing rectifier might be the problem. Here’s what to watch out for:

- Reduced Braking Performance: The brake may struggle to bring the lathe to a complete stop, resulting in sluggish or delayed gear changes.

- Complete Brake Failure: In severe cases, the brake might cease to function entirely, posing a safety hazard.

How to Diagnose a Faulty Rectifier

Before taking your lathe apart, it’s wise to perform some initial checks. Here’s how to diagnose a potentially faulty rectifier.

- Gather Your Tools: You’ll need a multimeter set to measure DC voltage. Consult your lathe’s manual for the location of the brake terminals.

- Isolate the Brake: Turn off and unplug the lathe for safety. Locate the brake on your lathe (refer to the manual if needed).

- Measure the Voltage: With the multimeter set to DC volts, carefully touch the probes to the two terminals on the brake. Activate the brake using the lathe’s controls.

- Interpret the Results: Compare the measured voltage with the recommended values for your lathe’s swing size:

- 15″ or 19″ swing: Expect a reading between 50-60 volts DC.

- 24″ swing: You should see around 90 volts DC.

A Significant Drop? Time for a Replacement

If the measured voltage falls significantly below the recommended values, the rectifier is likely the culprit. Remember, a properly functioning brake is vital for safe lathe operation.

Don’t attempt to modify or repair the rectifier yourself. Instead, source a replacement specifically designed for your lathe model.

You’ve Diagnosed the Rectifier, What Next?

Let’s assume you’ve tested the rectifier, and it’s functioning correctly.

The next step is to check the ZVM. This switch ensures the brake comes to a complete stop before initiating the gear change. A faulty ZVM might not send the necessary signal to engage the gear.

Other Potential Brake Issues

While a failing rectifier is a common cause of brake problems, it’s not the only potential issue. Here are two other areas that might cause issues.

- Faulty Magnetic Brake Armature: The brake relies on an electromagnet to generate stopping force. A crack in the armature can significantly reduce braking efficiency.

- Improper Brake Plate Gap: The brake plate needs to maintain a specific gap from the armature for optimal performance. Over time, this gap can widen, leading to a decrease in braking force.

Final Thoughts: Keeping Your Regal Running Smoothly

By understanding the servo shift system and how to diagnose brake issues, you can maintain the smooth operation of your vintage Regal lathe.

Remember, a properly functioning brake is essential for safe operation.

If you suspect a problem, consult LeBlond. We can service your Regal in the field or over the phone.

- Call +1 (888) 532-5663 and select Option 3 (Monday – Friday 8am – 5pm ET).

- Remember our Summer Machine Sale where you can get up to 10% off new LeBlond or K.O. Lee equipment.

- Contact a Sales Engineer by calling the above number and selecting Extension 2.

- Or just leave a comment below

We look forward to hearing from you.

I have a LeBlond Regal 19″, and when operating at the higher RPMs the brake is constantly making banging/knocking noises, enough that it sounds like all the bearings inside the headstock are made of granite rocks. I originally opened the head access cover and ran it briefly, but all the noise was coming from the large end cover with the gearing inside. After cleaning up years of grit/oil buildup, I noticed that the brake pins on the main belt drive pulley move freely in and out under spring tension. Any help on adjusting/fixing this?

Thanks for your query Drew. Someone will contact you. For immediate service, call 888-532-5663 and select Option 3.