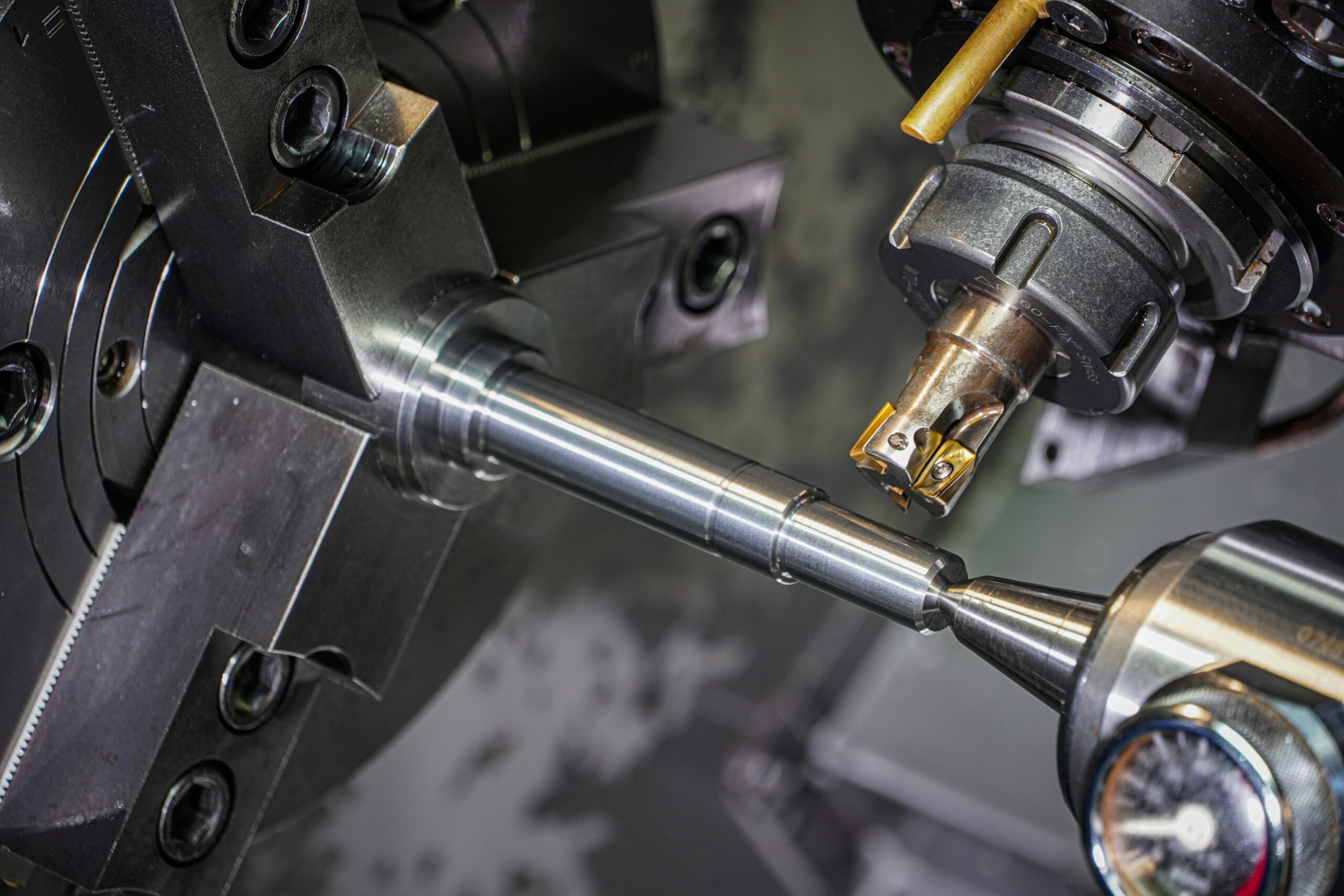

Keeping your tools sharp and effective is the key to a clean, efficient cut. Whether you’re a seasoned machinist or just getting your hands dirty in the shop, understanding the right machine tool inserts and coatings can make all the difference.

wear parts

Lathe Tooling & Uses – What You Need to Know

Producing a quality part on a lathe means knowing the end results needed and applying appropriate application of the tool.

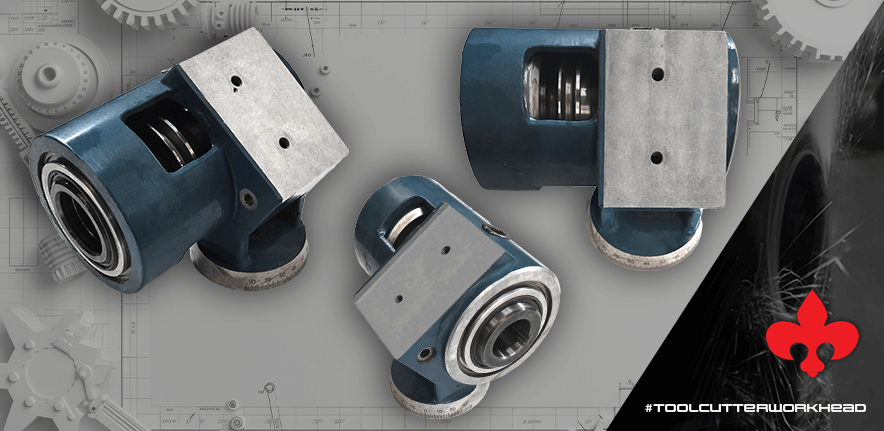

Check Out This Must-Read Machine Shop Hack

Your K.O. Lee tool & cutter grinder's workhead is locked up. You're staring down a bill of around $30k for a new machine that is used to sharpen, shape and recondition cutting tools such as drills, milling cutters, reamers, taps and others. But here's the...

Four Ways to Improve Machining Productivity

A place for everything and everything in its place. In the machine shop, it couldn’t ring truer. Here are four ways metalworking machinists can better organize their workspaces for improved efficiency and productivity:

Stay on the Cutting Edge With These Machining Tips

Are you on the cutting edge when it comes to sharp tooling? Dull and damaged tooling can create scrap and downtime if not properly monitored and replaced. Learn how to stay on the cutting edge with these four tips.

When the Chips are Down LeBlond Pulls You Through

When chips are not managed during machining parts, scrap occurs. You can always bet on LeBlond when machining gets tough. LeBlond helps when the chips are down. In this case, literally when chips are cut from a workpiece. Chips are an important aspect of metalworking....

Get Creative When Machine Shop Floors Get Cramped

Get Creative When Machine Shop Floors Get Cramped Precautions Machinists Can Take to Avoid Common Machinability and Material Selection Pitfalls Squeezing into an old pair of jeans that previously fit comfortably but are now too tight for your waistline is similar to a...

Machining Complex Metal Parts Requires Simple Solutions

Machinists must possess a deep understanding of machining principles, tooling, materials, & machine capabilities to produce complex quality parts. Know these 6 solutions to machining complex part pain points.

Best Solutions for Machinability and Material Selection

Become a manufacturing super star by following these 10 small part manufacturing tips. When put into practice they improve the final output on finished parts.