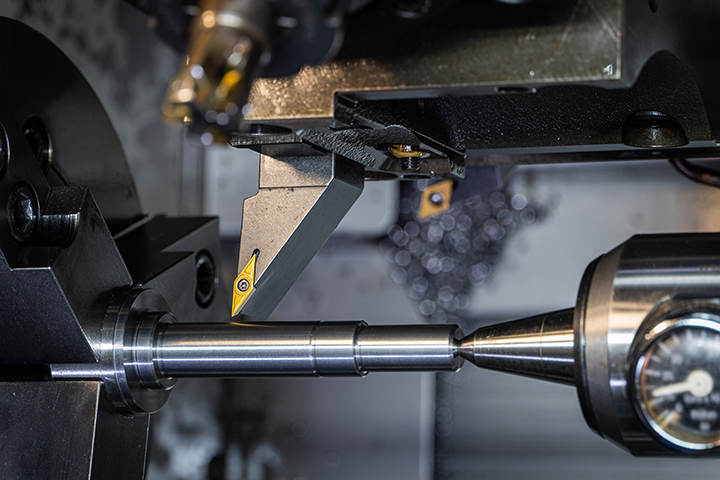

Signs of Tool Wear Machinists strive for perfection in every cut. Even the slightest deviation in precision metalworking can mean the difference between a flawless part and costly rework. Tool wear is inevitable, but early detection and correction can save valuable...

lathe tooling wear

Your Cuts Look Like Garbage. Here’s Why.

You fire up your lathe. Load your workpiece. Make the cut. And it looks like someone dragged a jackhammer across the surface. Welcome to chatter marks. The universal sign that your gibs are shot. Most machinists don't think about gibs until it's too late. They blame...

5 Tips to Manage Tool Overhang in Lathe Metalworking

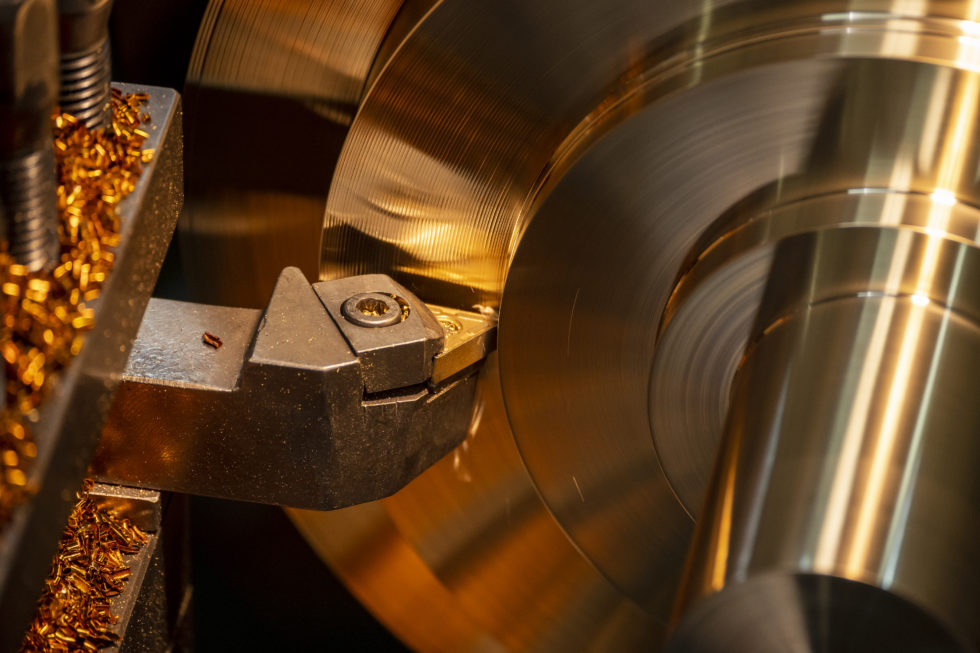

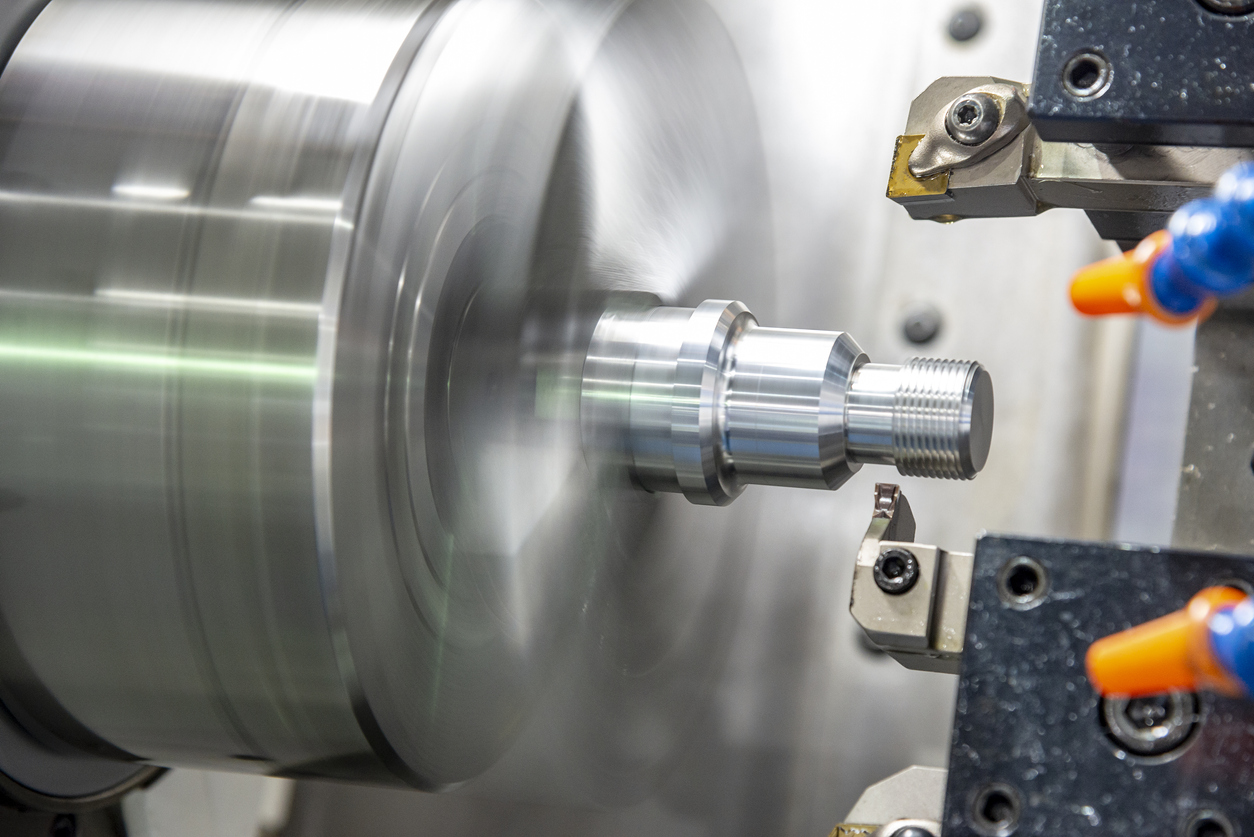

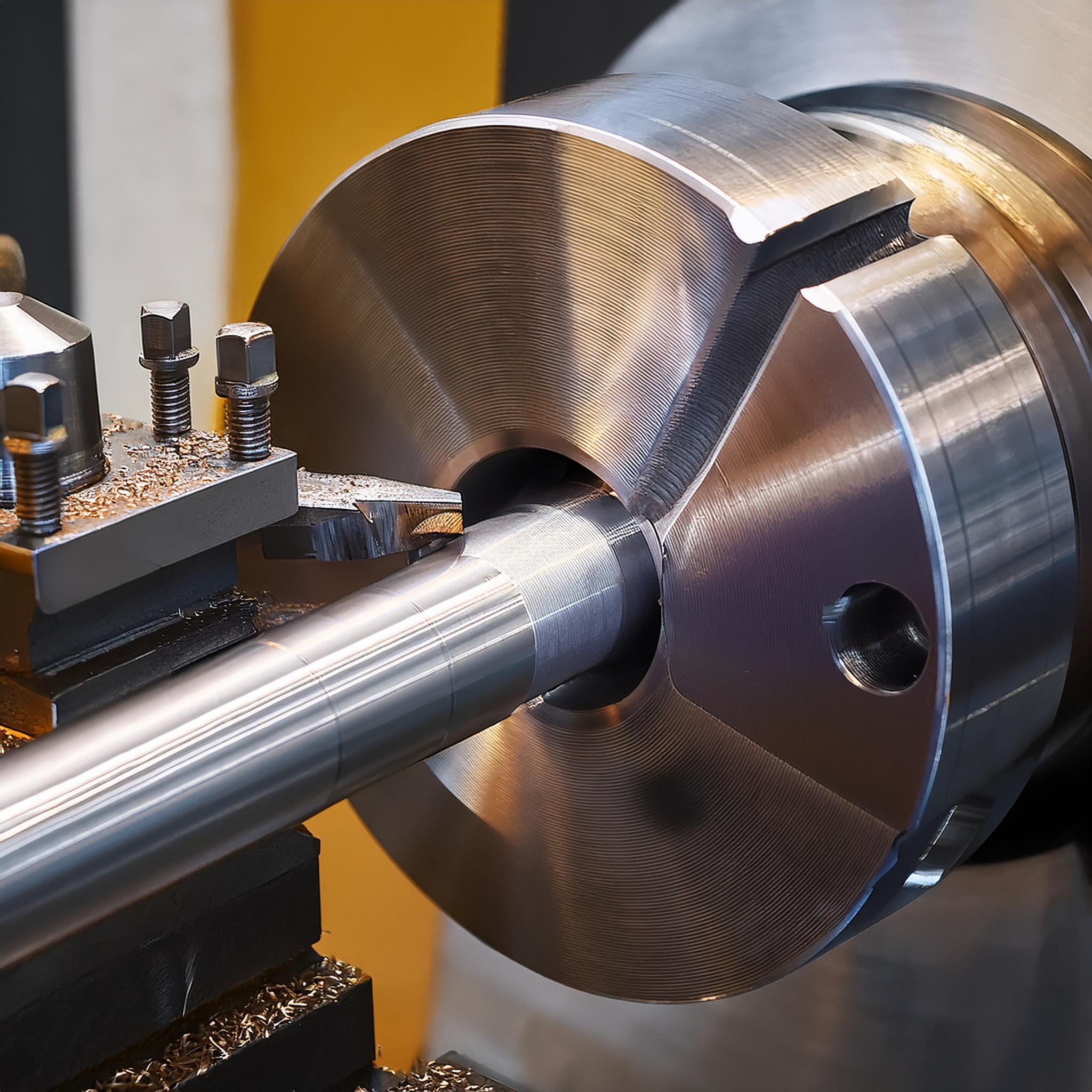

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

Lathes Get Machining Done

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

7 Essential Lathe Maintenance Tips for Smooth, Accurate Machining

A well-maintained lathe doesn’t just run better—it lasts longer, performs more accurately, and reduces downtime. Whether you’re operating a manual machine or a CNC lathe, implementing a structured maintenance routine is critical.

Can You Ace Our Lathe Terms Quiz?

Do you have what it takes to ace our machinist terms quiz? Test your lathe knowledge.

Mastering Chip Control

Metalworking lathes are versatile machines used primarily for shaping metal and other solid materials. They are essential in various industries for machining parts using techniques such as: Turning, Facing, Drilling, Knurling, Parting, Taper Turning and Thread Cutting.

Lathe Tooling Insert Shapes, Uses, Pros & Cons

Picking the right tooling insert for machining metal isn’t always easy—there are so many shapes, coatings, and materials to choose from. The wrong choice can lead to rough finishes, worn-out tools, or even scrapped parts. Tooling inserts are essential in machining, offering versatility and efficiency for various applications.

What Are Metalworking Lathes Used For?

Metalworking lathes are versatile machines used primarily for shaping metal and other solid materials. They are essential in various industries for machining parts using techniques such as: Turning, Facing, Drilling, Knurling, Parting, Taper Turning and Thread Cutting.