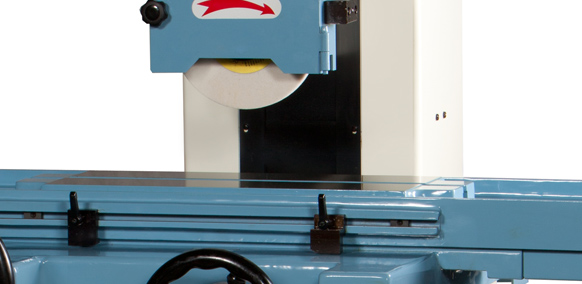

In our last post, we tied the blacksmith’s art of hand scraping that can be found on the ways of K.O. Lee surface grinders back to hand scraping tools that prehistoric man used in the Stone Age. In today’s post, we discuss why hand scraped ways improve the performance of a manual machine tool like the K.O. Lee surface grinder.

In an article on hand scraping in engineering.com, the author describes the need for hand scraping in machine tools to ensure smooth travel of moving parts:

Whether the work moves and the cutting tool is fixed, or vice versa, machine tools must use platens or tables traveling along precision ways. Straight, smooth ways are the key to close tolerance machining and all the control software in the world can’t compensate for a tool or table that won’t index repeatedly.

The author relates hand scraping in CNC machining but the point holds up for manual machine tools such as a K.O. Lee surface grinder and its cross slide ways that are precisely hand scraped and laminated with the thermoplastic resin Turcite B to reduce friction on moving parts and bearings.

Hand scraping ultimately allows a K.O. Lee surface grinder to run more precisely by creating a surface of, what the author of the engineering.com article, terms “high and low spots on the mating surfaces.”

Conventional wisdom might lead you to believe that a perfectly flat surface on a surface grinder would improve accuracy. This is not the case, as the high and low spots created by a blacksmith’s chisel-shaped scraper holds oil deposits and allows for “gliding, rather than sticking,” according to the engineering.com article. As a result, hand scraping improves machine performance by allowing the surface grinder ways to glide more precisely.

Hand scraped ways also improves accuracy and flatness in a K.O. Lee surface grinder. Regarding accuracy, engineering.com writes that scraping “is done to align components within millionths of an inch, allowing for consistently-held, tight tolerances.” The blacksmith’s chisel creates about ten contact points per square inch on the surface grinder ways that reduce rocking and increases balance when the machine tightens. This creates true flatness in the K.O. Lee surface grinder ways.

Don’t miss LeBlond’s promotion until May 31st where you receive a free two-axis Newall DP700 digital readout with the purchase of a K.O. Lee Surface Grinder. Check out the offer here. If you’re interested in new LeBlond manual lathes, K.O. Lee grinders or need original OEM parts for LeBlond, K.O. Lee, Standard Modern, Johnson Press, Deka Drill and W.F. & John Barnes equipment, fill out a contact form here.