Description

Digital Readout Systems: Newall NMS 800 DRO Digital Readout

The NMS 800 Digital Readout (DRO) is the newest in Newall’s range of premium readouts. The DRO hosts many productivity enhancing features that will increase machine tool efficiency. The NMS 800, when matched with Newall’s Spherosyn Serial and Microsyn Serial encoders, provides years of maintenance free, trouble free performance. Newall’s inductive encoders are simple to install and designed to provide consistent accuracy and reliability even under the harshest workshop conditions.

Newall Advantage

- Backed by a company with over 50 years of proven reliability in manufacturing DRO systems & linear encoders

- Encoders carry an IP67 rating – All electronic and measuring components are sealed from the environment

- Continually provides accurate readings even under the harshest shop conditions

- No cleaning or maintenance required

- Tolerant to shock and vibration

- No glass or tape to break or scratch

- Ease of installation—no backer bar or machined surface required

Warranty: 5 year mfg, 3 year No Fault*

*USA & Canada Only

*Varies by Region, Terms and Conditions Apply

General Purpose Functions

- 2, 3 or 4 axes configuration

- Inch/mm conversion

- Four user definable function keys

- Absolute / Incremental operation

- Axis pre-set / zero reset

- Zero approach warning (graphic and audio)

- Feed-rate display

- Newall Encoder auto-detection

- RPM display*

- Angular readings*

* requires rotary encoder

- Auto resolution detection*

- Linear and segmented error compensation

- Digifind / reference mark

- Centre find (establish workpiece midpoints)

- Programmable memory for datums and tools

- Built in calculator

- Undo function (move back up to eight steps)

- USB port for loading new firmware and

settings

- Sleep mode

- Scaling factor

Milling Specific Functions

- Bolthole circle / PCD calculations

- Line hole / grid array calculations

- Arc contouring

- Pocket / island milling

- Summing two encoders within the same plane

Lathe Specific Functions

- Radius / diameter readings

- Tool offset library (50)

- Taper calculation

- Vectoring (requires 3 axes)

Encoder Compatibility

Serial Input: Newall Spherosyn & Microsyn Serial, Propriety Signal not compatible with previous Newall

DRO Encoders (S2G/M2G).

Digital (TTL) Input: Newall TTL Encoders. Many third party TTL encoders including Rotary.

Contact your local sales representative for advise on compatibility.

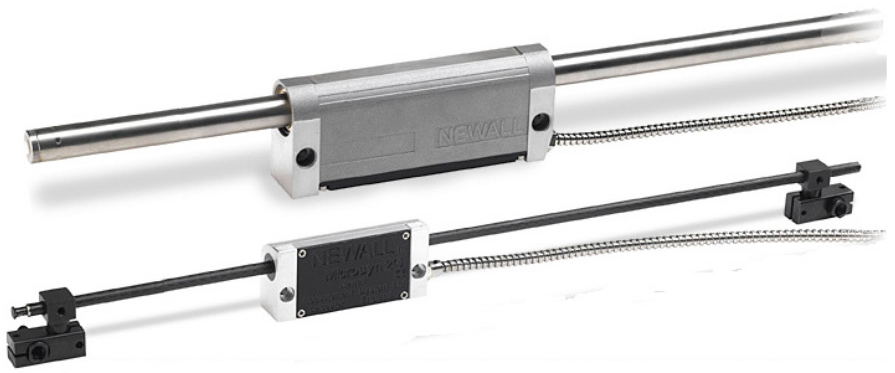

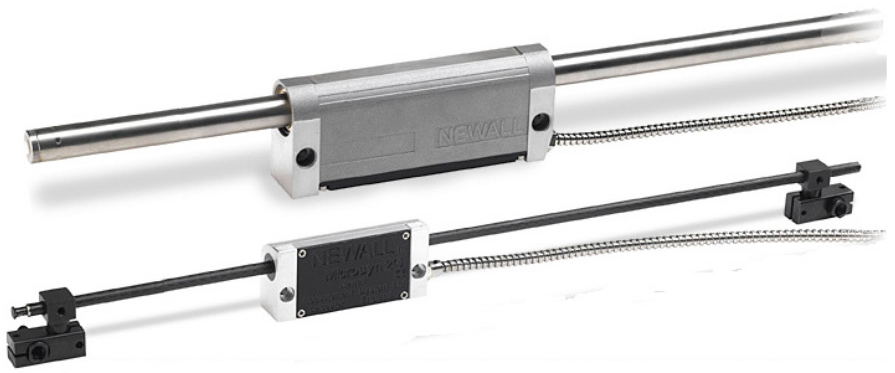

Linear Encoders for Newall DRO Systems

Spherosyn ™ and Microsyn ™ encoders are designed to give you consistent accuracy and reliability under even the harshest shop conditions. Based on the principle of electromagnetics, Newall’s analogue encoders embody a truly innovative design in which all of the electronic and measuring components are sealed and protected. The encoders carry an IP67 (NEMA 6) environmental rating and will continue to provide accurate and reliable readings even when submerged in water, oil and coolant.

Encoder Benefits

- IP67 (NEMA 6)

- Withstands dust, dirt, oil and other environmental conditions

- No mechanical wear characteristics

- Requires no cleaning or maintenance

- High tolerance to shock and vibration