Mills are indispensable equipment for machinists. They help machinists perform various machining tasks like shaping metal or plastic and creating slots, contours, holes and flat surfaces.

Mechanical variable speed mills and electronic variable speed ones are two popular choices.

We’ll discuss these mills in this post. We will define them, their benefits, cons and applications.

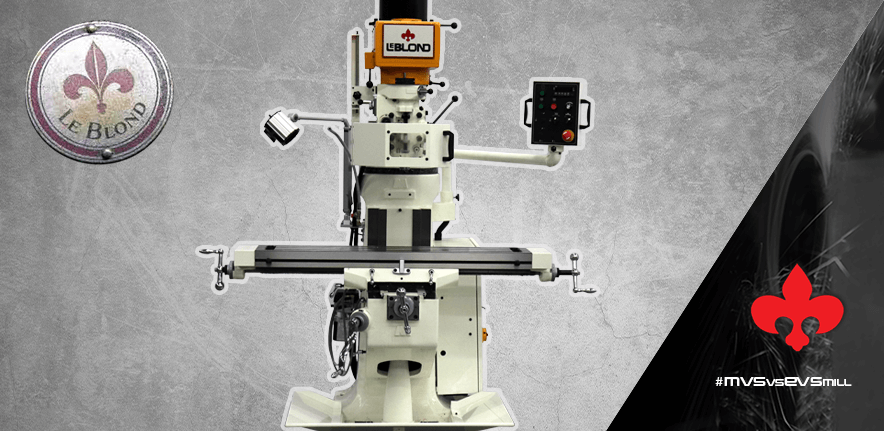

What’s a Mechanical Variable Speed Mill?

A mechanical variable speed (MVS) vertical knee mill uses a mechanical system of pulleys and belts to adjust the spindle’s speed.

You’ll need to change the speed mechanically when using a mechanical speed mill to increase or decrease RPMs (Rotation per Minute).

Benefits of Mechanical Variable Speed (MVS) Mills

MVS mills are less complex than variable speed models. These mills have several benefits, including:

- Less Expensive

Mechanical variable speed mills are less expensive compared to their electrical counterparts. They are also easier to maintain. Their components are relatively inexpensive. It is generally more inexpensive to fix or replace their faulty components when they fail.

- Easy to Use

As mentioned, MVS mills come with a less complicated design. These machines are perfect for beginners and operate with a limited understanding of mechanical systems. They provide a basic understanding of the machining process.

- Reliable

Because MVS mills have few electrical components, they are less susceptible to electronic malfunctions.

Shortcomings of MVS Mills

Like other machines, mechanical variable speed mills have their unique limitations. Here are some shortcomings.

- Limited RPM Range

With a LeBlond MVS knee mill, machinists have a limited RPM range of 60 to 4,200 RPMs. So, it’s impossible to achieve machining applications that require a higher RPM range when using a mechanical variable speed mill.

- Imprecision

Adjusting RPMs using pulleys and belts can lead to imprecise speed adjustments. Operators carrying out their machining applications using mechanical variable speed mills should not change spindle speeds unless the motor is running.

- Unexpected Maintenances and Replacements

Mechanical variable speed mills can be easier and cheaper to maintain. The major drawback of these machines is that their pulleys and belts are prone to wear out over time. This can create unexpected downtime when procuring replacement parts.

What is An Electronic Variable Speed (EVS) Mill?

It’s a more modern model of a vertical knee mill that utilizes a VFD (Variable Frequency Drive) to control the motor’s speed electronically.

With this mill, you control everything on a control panel. Like a lathe, this milling machine features an RPM display. Machinists adjust RPMs with a dial that is located on the control panel.

Benefits of Electronic Variable Speed Mills

The benefits of using electronic variable speed mills include:

- Optimized machining

The VFDs in EVS mills allow operators to tailor RPMs to their precise machining applications.

You can conveniently alter the spindle speed to suit the material you’re cutting with an electronic mill, helping you get cleaner cuts and excellent surface finishes.

- Ease of Customization

Electronic variable speed mills allow machinists to customize the entire milling process to suit specific applications.

These milling machines are handy for executing delicate machining applications and other applications that demand extra precision.

- Material Versatility

Machining entails utilizing various materials that require varying cutting speeds to prevent workpiece damage.

Electronic variable speed mills allow machinists to cut different materials precisely, preventing unexpected damages.

Disadvantages of EVS Mills

The cons of these mills include:

- Pricier

These machining devices are generally more expensive than their MVS counterparts. They have top-notch features like VFDs, which explains the higher price than older models.

- Complex Designs

Electronic variable speed mills come with more complex electrical layouts.

Their complex designs mean these machines can demand specialized repair if any electronic components fail.

What Machining Applications Are Suitable for Electronic Variable Speed Mills?

Here are examples of applications best suited for EVS mills:

- Material Specific Machining

Due to VFD technology, electronic variable speed mills help operators adjust RPM speed for specific material machining.

Whether working with plastics, steel or aluminum, an EVS mill enables you to achieve clean cuts.

- Delicate Machining

Electronic variable speed options offer a better and more controlled approach to working on delicate machining applications and other applications requiring adherence to intricate details.

- General Machining

Electronic variable speed knee mills are great for multiple machining tasks, including material slotting, drilling, pocketing and facing.

Choosing between MVS & EVS Mills

Consider these factors when choosing an MVS or variable speed milling machine.

- Complexity of the Machining Application

Complex machining projects require greater control and flexibility. An electric option is suitable for complex machining applications or applications requiring machinists to utilize diverse materials.

- Budget

A mechanical option is preferable for budget-conscious machinists prioritizing affordability.

But, if you aren’t working on a tight budget and you’re looking for a mill that can offer better performance, the EVS mill would better suit your needs.

- Expertise Level

A mechanical variable option is ideal for novice machinists due to its simplicity and ease of use. It’s excellent for operators who can only execute simple machining applications.

If you’re a more experienced machinist working with more complex designs, the EVS mill is your best choice.

- Precision control

Since a LeBlond EVS mill offers greater control over precision and a higher RPM range (60 to 5,000 RPM compared to the mechanical’s 60 to 4,200 RPM), it would be the best fit for machinists who prioritize precision control when deciding between an electronic or mechanical option.

Contact LeBlond for EVS & MVS Milling Machines

Choosing the perfect mill is the first step to having a successful machining project.

Every mill offers unique benefits tailored to different machining applications and needs, from top-notch EVS mills to more traditional MVS ones.

Interested in a LeBlond mill?

- Call +1 (888) 532-5663 for urgent help identifying a mill that perfectly meets your machining applications.

- Or visit THIS PAGE to review our extensive lineup of MVS and EVS mills.

- Or leave a comment below!

We look forward to hearing from you!