LeBlond In-Stock Machines Are a Winning Hand

An in-stock LeBlond machine is the best card for Phil to play, even if he doesn’t realize he is gambling. Phil is a machinist who supplies parts for the automotive industry. Uptick in Business? He expects business to pick up with a flurry of recent trade deals,...

Keep Your K.O. Lee Tool & Cutter Grinder Running Like a Beast

Your K.O. Lee tool and cutter grinder is a precise monster of a machine. It's built to sharpen end mills, cut gears and handle demanding tooling work day after day. But like any workhorse, it needs the right parts to keep performing. When critical components...

7 Essential Lathe Maintenance Tips for Smooth, Accurate Machining

A well-maintained lathe doesn’t just run better—it lasts longer, performs more accurately, and reduces downtime. Whether you’re operating a manual machine or a CNC lathe, implementing a structured maintenance routine is critical.

Stop Wasting Time. Get the Newall NMS 800 DRO.

Your old lathe is bleeding money. Every second you spend squinting at grimy Vernier dials is profit walking out the door. The Newall NMS 800 Digital Readout changes everything. No more guessing. No more mistakes. Your Current Setup is Killing Productivity Cross-slides...

Your Vintage K.O. Lee Surface Grinder Just Lit $50k on Fire

That's what happens when you ignore surface grinder maintenance until it's too late. You have to buy new equipment in the neighborhood of five figures. I dunno — maybe you should just burn stacks of money instead. LeBlond Service Manager Christopher Smith has seen it...

Tips for a Smooth Industrial Lathe Installation

So, you’ve taken the first steps in preparing for a lathe installation—you’ve identified the equipment weight, contacted a rigging company, and confirmed that disassembly and fluid drainage are (mostly) optional. Great! But the process doesn’t stop there. A successful...

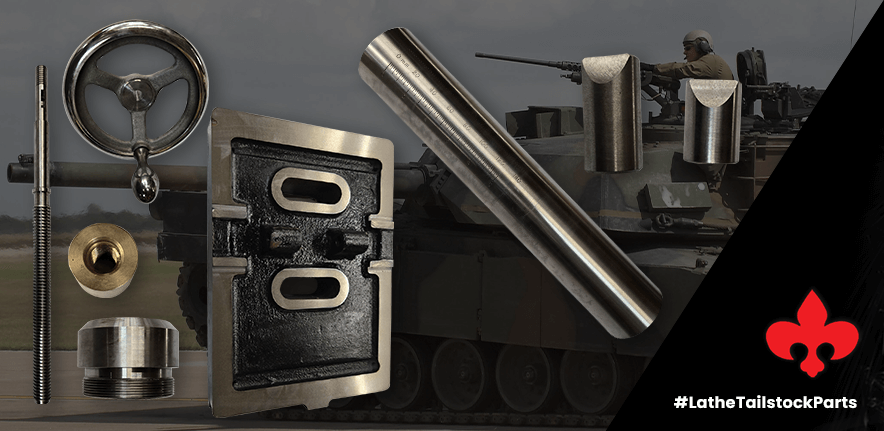

Lathe Tailstock Parts Are Tougher Than an Abrams Tank (But These 8 Parts Will Eventually Break)

Here's the scorching truth about lathe tailstocks: They're built like tanks, but even tanks need maintenance. After five years selling LeBlond parts, Tim Fuller has seen it all. Dropped tailstocks. Beaten spindles. Parts thrown away by mistake. The carnage is real,...

LeBlond Stands With Machine Tool Schools

May 28, 2025 Dear Machine Tool Leaders, Last month, President Donald J. Trump announced his administration’s intention to halt $3 billion in research grants and redirect them to trade schools and other institutions in the United States. This policy initiative is...

5 Easy Tips for Extending the Life of Your Lathe

When the first explorers of America set out to find the Fountain of Youth, they never would have expected it right in the middle of a machine shop. The key to a lathe’s long life is through sticking to five easy lathe maintenance tips. An experienced machinist must...

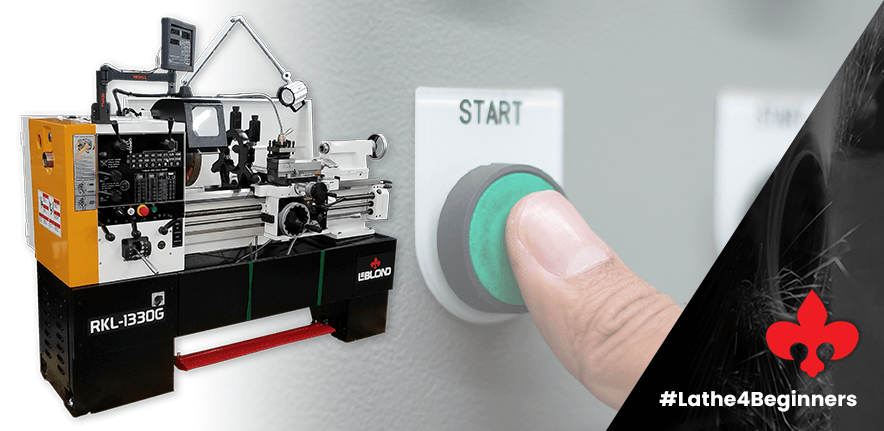

Lathe for Beginners

The manufacturing world is facing a crisis. As veteran manual machinists retire, companies are struggling to replace them. Schools eliminated manual machining from curricula for years, and now companies are paying the price. But there's a resurgence...