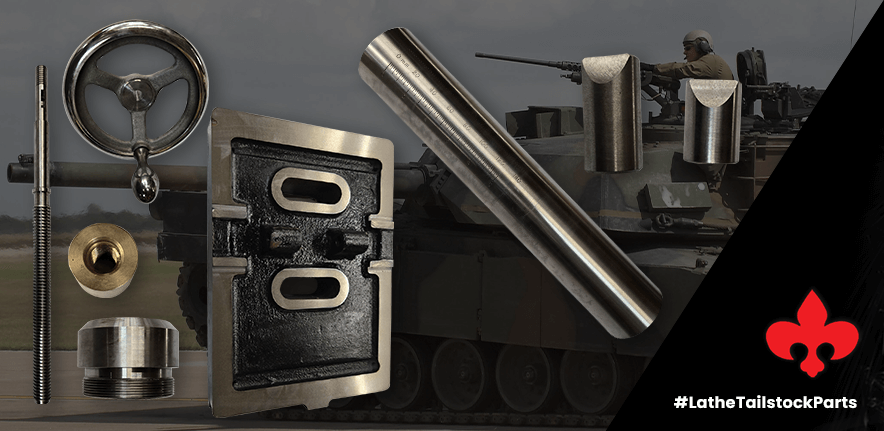

Here’s the scorching truth about lathe tailstocks: They’re built like tanks, but even tanks need maintenance.

After five years selling LeBlond parts, Tim Fuller has seen it all. Dropped tailstocks. Beaten spindles. Parts thrown away by mistake. The carnage is real, but so is the solution.

Let’s break down the eight tailstock parts that keep your LeBlond running—and what happens when they don’t.

The Workhorses: Screw and Nut

Tailstock Spindle Screw

Background Image Via Scott Chapman

This is your tailstock’s muscle. It moves the spindle in and out, left and right, doing the heavy lifting every single day.

The screw is a wear part, plain and simple. But here’s what surprises most machinists: some LeBlond Regal lathes run 30+ years before needing replacement.

“It really just depends on how much the machine is used,” Fuller explains. Use it for eight hours daily? You’ll replace it sooner. Once a week? It’ll outlast your mortgage.

Tailstock Spindle Nut

Think of this as the screw’s partner in crime. It keeps the screw straight, prevents it from wandering off course and actually does the pushing and pulling of the spindle.

Here’s the kicker: It’s made of brass. That means it dies before the screw does.

“You’ll replace a couple of nuts before you replace a screw,” Fuller notes. Light users? You’re looking at 10+ years before replacement.

The Heavy Hitter: 5MT Tailstock Spindle

This beast holds your workpiece. The 5 Morse taper tells you you’re dealing with serious iron—19-inch machines and up.

But don’t confuse size with fragility. “As long as it’s used properly, it’ll last forever,” Fuller says.

The problem? People beat on spindles to get parts in and out. Don’t be that person.

For context: heavy-duty lathes use 6 Morse taper or bigger. We’re talking industrial-grade equipment here.

The Forgotten Heroes

Tailstock End Cap

Fuller has sold maybe three of these in five years. It’s the cap on the back where the screw goes through and the handle attaches.

“The only parts that ever really get changed are the screw, spindle and nut,” he explains. Everything else? Only when something breaks.

Tailstock Handle

Same story. It never fails unless someone drops it or rams something into it.

How does a machine fall over? Moving buildings with forklifts. It happens more than you’d think.

Upper & Lower Binder Bushings

These work in tandem, pressing against the spindle to lock it in place. Think of them as your tailstock’s parking brake.

Fuller might sell one set per year. Maybe two. Usually during complete Regal rebuilds, not because they’re actually worn out.

The Disappearing Act: Tailstock Block

This part holds your tailstock to the machine bed. It rarely wears out. If you run your Regal lathe 24/7, it may need to be eventually replaced.

But it does get lost. Constantly.

“They’ll take it off and put it somewhere, and somebody accidentally throws it away,” Fuller says with a laugh.

The solution? Better training. Keep track of your parts.

The American Advantage

Every single one of these parts is made in Cincinnati, Ohio. If you buy LeBlond Regal replacement parts, be assured you’re getting Made In the U.S.A.!

“Some of the older guys believe that the older machines are better made, and they like American-made machines,” Fuller explains. With tariff talk heating up, that’s becoming more relevant every day.

Contact LeBlond For Lathe Tailstock Parts

Your LeBlond tailstock is built to last decades. The spindle screw and nut will eventually wear out—that’s physics. Everything else? Only if you drop it, hit it or lose it.

Want to extend part life? Use your equipment properly. Don’t beat on spindles. Train your people. Keep track of small parts.

And when you do need replacements? You’re getting American-made quality that’s been proven in shops for generations.

If you need to order tailstock parts for your legacy LeBlond, please contact us:

- Find online parts ON THIS PAGE.

- Call +1 (888) 532-5663 (Monday-Friday 8am- 4:30pm ET) & select Option 1.

- Or leave a comment below!

We look forward to hearing from you!

Tim

A comment on the nut. If you made the nut out of bronze instead of brass, it would last much longer.

I am really happy to see Leblond making some KO Lee machines.

John Schuetz

Noted, John. Thanks for the comment. Let us know if you need K.O. Lee parts.

I love my three LeBlond lathes!!! I’ve completely restored two of them. Third one is on the list.

Danny, appreciate it! Let us know if you need parts for your third go around.

Do you make a tailstock block that is thicker than original? I have seen more than one tailstock shimmed at the mating surface with the block, and I may have to do that to my machine soon.

Steve, we’ll look into that for you. Thanks for reaching out.