Need parts for a lathe headstock?

While machinists focus on the finished workpiece, it’s the headstock parts hidden within that truly determine performance.

The LeBlond Regal Servo Shift—a machine that bridged the gap between manual and CNC lathes—contains engineering marvels that continue serving shops nationwide.

This machine was introduced in the 1960s and had a solid 30-year run when tens of thousands of lathes with automatic options were installed in North America alone before computer numerical control lathes became dominant.

Before we explore parts for this machining mainstay, let’s serve up a softball for beginner machinists.

What Is a Lathe Headstock?

The headstock is a crucial component of a lathe machine, essentially serving as the power center and main support structure.

Located on the left side of a conventional manual lathe on the front end of the lathe bed, the headstock houses the power switch, motor, drive mechanisms, control panel and spindle assembly that provide rotational power to the workpiece.

The headstock performs several vital functions:

- It supports and rotates the workpiece by providing the primary driving force to the part suspended above the lathe bed

- It maintains precise alignment and stability during machining operations

- It allows for changes of spindle speed via the motor through various gearing mechanisms

- It secures the workpiece using different holding devices like four-jaw chucks and collet chucks

The headstock is fundamentally what makes a lathe cutting tool function as a rotary machine tool, enabling operations like turning, facing, drilling and threading by engaging the control panel and motor and rotating the workpiece against stationary cutting tools.

With a definition in the books, let’s go back in time on the LeBlond Regal Servo Shift model.

LeBlond Regal Servo Shift Lathe History

The LeBlond Regal Servo Shift lathe was a revolutionary cutting tool when introduced in the 1960s, combining manual operation with automated speed selection.

These durable American-made lathes continued production through the 1990s and remain in service in many machine shops, educational institutions and manufacturing facilities throughout North America.

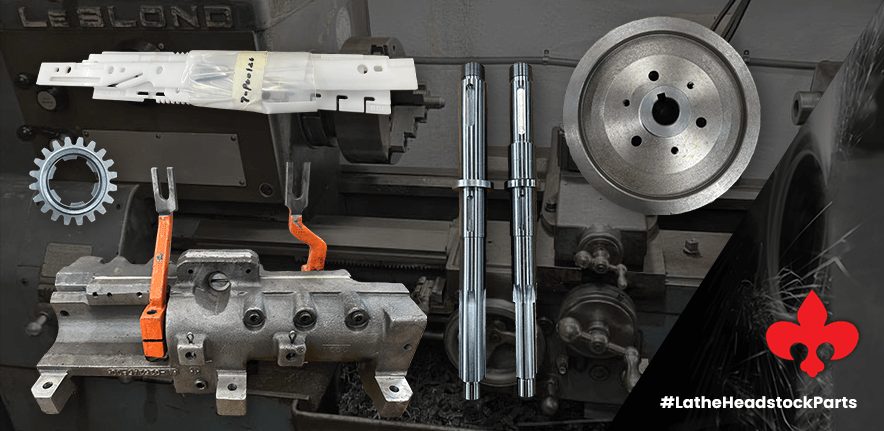

LeBlond Regal Headstock Parts Examined

As with any precision equipment with decades of service, parts occasionally need replacement.

Based on an exclusive interview with LeBlond Parts Sales Representative Tim Fuller, we’re breaking down five critical headstock components every Regal Servo Shift owner should understand.

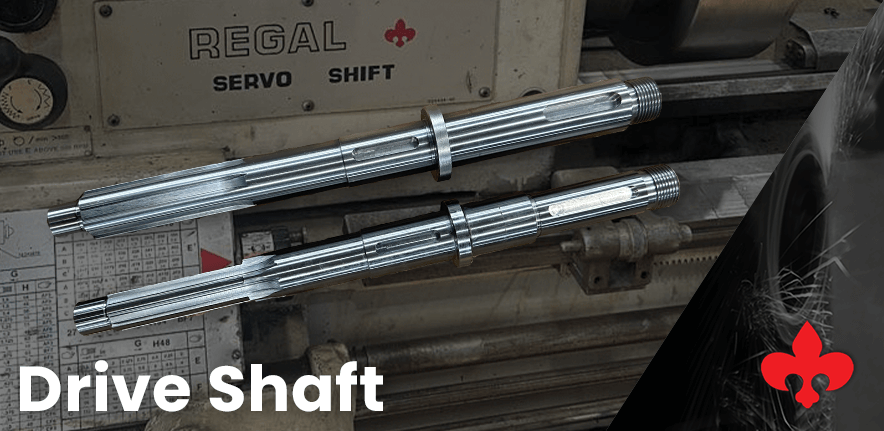

1. Drive Shaft

The drive shaft is what Tim Fuller describes as “the low gear of the machine.” This essential component serves multiple functions:

- Acts as the primary power transmission from the motor to the headstock

- Houses the braking mechanism behind the pulley

- Provides the foundation for the entire power train

According to Fuller, “The drive shaft, it’s the low gear of the machine and that’s also the drive shaft, that’s where the brake is off the drive shaft, behind the pulley, so that runs off the motor.”

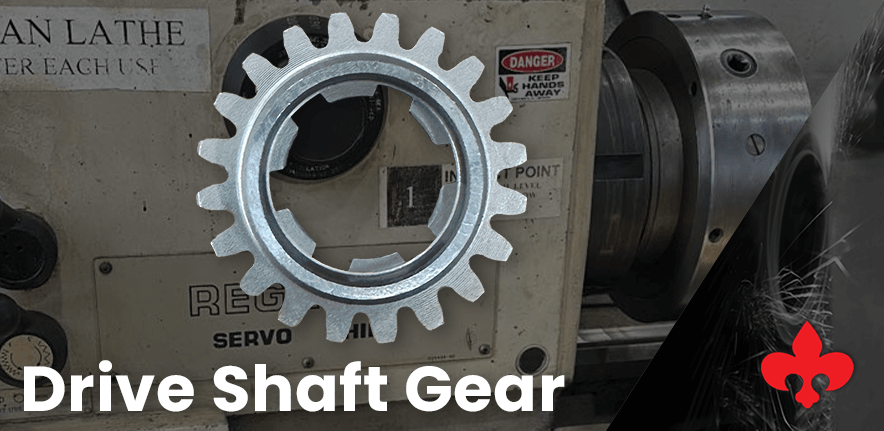

2. Drive Shaft Gear

The drive shaft gear connects to the drive shaft and initiates motion throughout the headstock’s gear train. As Fuller explains, “Without the driveshaft, none of the other gears will move.”

This component interacts with the intermediate shaft where sliding gears move to create different speed configurations: “When the gears slide back and forth on that shaft, they’ll hit the high-speed shafts in different ways.”

Like many headstock components, the drive shaft gear rarely fails without cause: “Nothing goes wrong with them unless someone inadvertently crashes them. You’re not just going to have pieces break on that unless something comes to a stop too quickly.”

The term “crashing” refers to situations where the workpiece or tooling collides with the headstock spindle, causing an immediate stop that transfers damaging force through the drive train and business end of the lathe.

3. Valve Slide

The valve slide, identifiable as a white plastic component, is unique to the Servo Shift system. This critical part enables the automated spindle speed selection that made the Servo Shift revolutionary.

“That’s for the Servo Shift. That’s how you select your gears, how you select your speeds. That goes from the low to high speed, all in one little knob, so the Servo Shift activates all that,” explains Fuller.

The valve slide works in conjunction with the speed selection dial located on the front of the headstock. This allowed operators to smoothly transition between speeds ranging from as low as 30 RPM to as high as 1800 RPM, depending on the specific Regal model.

As a plastic component subject to wear, valve slides are one of the more commonly replaced parts. Fuller notes that “because they’re plastic parts and over time could wear out,” and “sometimes if there are metal flakes in between, it might leave grooves inside.”

Valve slides are Original Equipment Supplier (OES) parts. They, like all LeBlond parts, are manufactured to exact specifications through a specialized process where molds are created, then shaved down to the finished component.

Fuller advises against DIY efforts. The valve slide’s precision manufacturing means attempting to fabricate your own replacement is not recommended.

4. Headstock Pulley

The headstock pulley (specifically the V-belt pulley) is immediately recognizable by its circular design with multiple bolt holes—typically three larger and three smaller holes. This component is fundamental to the lathe’s operation.

Fuller explains its importance: “That pulley operates at slow speeds also because that’s what’s attached to the motor. That pulley runs the whole machine. That’s where the start of the machine goes because it’s run from the motor pulley up to there. That gets it started.”

In the power transmission sequence, “it turns the gears to turn the spindle,” rather than directly turning the spindle itself.

While generally durable, the headstock pulley can suffer damage in certain circumstances: “If they crash it or something, that pulley could get bent or warped. The insides of it usually get warped a little bit because the brake attaches to that.”

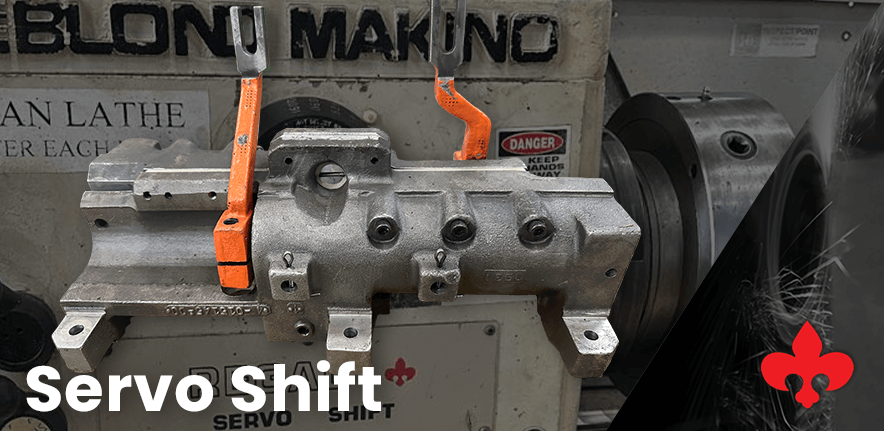

5. The Servo Shift System

The Servo Shift mechanism as a whole was LeBlond’s innovative approach to simplifying lathe operation and making machining automatic before the introduction of CNC lathes.

Fuller explains that “where you don’t have handles, you just have a knob, so you don’t have to worry about shifting into the different gears, using two different handles shifting into the gears, that Servo Shift just makes it quicker to operate.”

This technology bridged the gap between fully manual lathes and CNC lathes, offering some automated functions while maintaining the flexibility and accessibility of manual operation.

See Video of LeBlond Regal Headstock Parts

If the above pictures aren’t enough, watch LeBlond Service Manager Christopher Smith’s video detailing headstock parts as part of a LeBlond lathe restoration project.

If you are taking up a LeBlond lathe restoration, our OES parts are indispensable.

Protecting Your Vintage Lathe Investment

When asked about the best way to protect a LeBlond Regal headstock, Fuller’s advice was straightforward: “Just make sure when training someone, they are familiar with the dos and don’ts of operating the machine.”

.

Who Still Uses Regal Servo Shift Lathes?

Despite being out of production for decades, these lathe machines remain widely used.

When asked about current users, Fuller revealed an impressive range: “We sell parts to large and small companies that are involved in a wide sector of manufacturing industries as well as to hobbyists and gunsmiths. It doesn’t really specify one sector.”

While demand for parts has decreased somewhat over recent years, there are still “tens of thousands” of these machines in service across North America.

Interestingly, Fuller notes that through the years, our current orders are from companies that we haven’t sold to before, indicating just how widely distributed these lathes remain.

Why Choose a LeBlond Servo Shift Over a CNC Lathe?

For operations producing one-off parts rather than high-volume production runs, the Servo Shift offers an economical alternative to CNC machines. While CNC technology offers advantages for repeated identical parts, the Servo Shift provides a balance of efficiency and flexibility that continues to serve machinists well for certain applications.

As these machines continue aging gracefully, understanding their key components becomes increasingly important for maintenance and preservation.

Contact LeBlond For Headstock Parts

With proper care and operator training, a LeBlond Regal Servo Shift lathe can continue delivering precision results for decades to come.

If you have questions about our OES lathe parts, please get in touch.

- Find online parts ON THIS PAGE.

- Call +1 (888) 532-5663 (Monday-Friday 8am- 4:30pm ET) and select Option 1.

- Or leave a comment below!

We look forward to hearing from you!

Video Transcript

Hey, guys. Christopher Smith here with LeBlond, and gonna talk to you this video about parts for your old lathe.

As you can see behind me, we have an old lathe that we wound up, we took in on trade. It’s a 1981, 19″ x 54″ LeBlond Makino servo shift lathe. We do periodically take them in on trade, just to keep us out here in the shop kind of up to date in how to work on them so we can better help service you guys.

We do not take them in regularly to rebuild for customers or nothing like that, just once in a blue moon. This is only the second one in the eight years that I’ve been here that we have [inaudible 00:00:42]. But I did want to let you know, we can be the one-stop shop for you guys for all your parts needs.

Right now, what I’ve got laid out here is a lot of the stuff for the headstock, and this one being the servo shift. We got the servo shift already out where we go through it, rebuild, see if there’s anything going on with it. And new, the biggest thing is going to be your bow slide that does the control and all that for it as well.

Then everything else we are taking out new. Shafts, tapered roller bearings, all your seals, gears, detent, arms, and yokes. Like I said, we keep all this stuff in stock. That way we can have you back up and running as soon as possible.

This is the old brake off of this machine, but here in the box we sell the new ones. Timing belts, v-belts. So basically what you see behind me on this lathe is we just kind of started out. We’ve already been working on it, kind of broke it down. But something that really a lot of people tend to miss and don’t get, see, this machine’s never really been taken out and cleaned. All these chips that build up underneath the head, and particularly right here behind the electrical box.

So we’ve taken the electrical box off, and this whole area was completely jam-packed with chips. And what that’s going to do is actually going to cause your hydraulic pump to get hot and not live its life. So we’re going to take this thing all apart, get all the motors, electronics off of it. We’re going to take it outside, pressure wash it, give it a new paint job, put it all back together.

One thing that always amazes me, and I really enjoy about these, is on the outside it looks pretty rough, but when you take this cover off, and you look down inside one of these, how extremely clean it is. Yeah, there is some dirt and stuff, but the fact that, you know, it being a sealed unit, they’re always fairly clean inside.

But yeah, just want to get it out, inspect all the gears, all the teeth. And if you’re struggling with something on that we can help out with, but we have everything you would need to rebuild your old lathe. Or if you just need, you’ve got one broken gear, we got that broken shaft, all the bearings, and that’s what we’re here to help you out with, and what’s been keeping LeBlond going for so long.

We may update throughout, however long, whenever we get time to work on this. Just matters what our workflow in the shop here is. So please reach out to us anytime you need parts. Hit us up. Go to leblondusa.com and request a quote. We’re here for you. Thank you.