The manufacturing world is facing a crisis.

As veteran manual machinists retire, companies are struggling to replace them. Schools eliminated manual machining from curricula for years, and now companies are paying the price.

But there’s a resurgence happening.

Educational institutions are rediscovering what LeBlond has known all along: mastering manual machining fundamentals creates versatile, problem-solving machinists who understand the craft on a deeper level.

Lathes For Beginners vs. Standard Lathes: The Truth No One Tells You

Let’s cut through the marketing hype. When schools ask us about an “educational lathe for beginners,” they’re often surprised by our answer:

There’s virtually no difference between our educational lathes and standard industrial machines.

That’s right. LeBlond’s metal lathe for newbs is an genuine industrial-grade model, built with the same rugged construction and precision components as those running in shops across America.

The only significant difference?

Our educational models don’t come standard with a taper attachment – a specialized component that allows cutting tapered shapes on parts.

This isn’t a downgrade – it’s strategic.

Many schools never use taper attachments, and removing them as standard equipment keeps costs manageable while delivering the full industrial experience students need.

The Machines That Are Rebuilding America’s Manufacturing Workforce

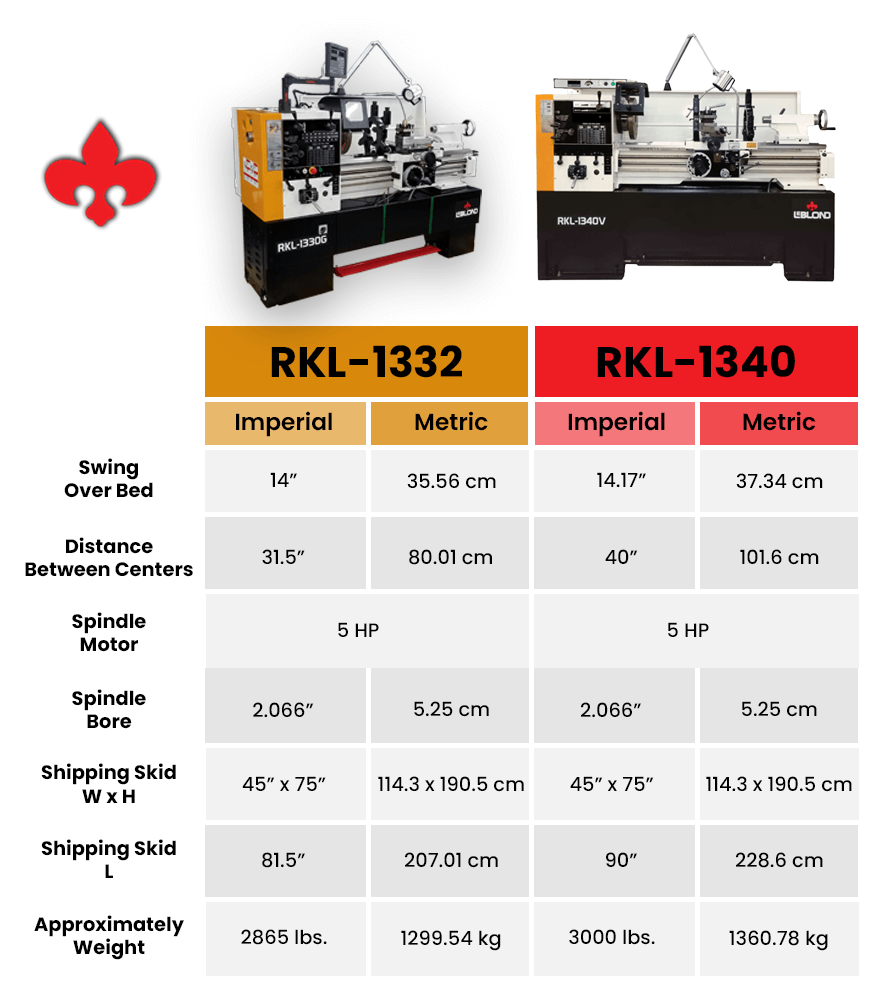

The backbone of LeBlond’s educational lineup consists of two powerhouse models that dominate the school market:

LeBlond RKL-1332 Metal Lathe: The Space-Saving Workhorse

For schools with limited floor space but unlimited teaching ambitions, the LeBlond RKL-1332 metal lathe delivers industrial capability in a compact 14″ x 32″ capacity. When you’re trying to equip a full classroom, those 8 inches saved per machine add up fast.

LeBlond RKL-1340 Lathe: The Gold Standard

The slightly larger RKL-1340 metal lathe gives students extra working room with its 14″ x 40″ capacity, making it ideal for more advanced projects. Both machines are available in gearhead and electronic variable speed spindle configurations to match your teaching approach.

Need a quick sketch of the two different machines for beginners?

Built to Survive Teenagers (And Everything Else)

School administrators don’t mince words when they call us for a small machine metal lathe to train students for a machine shop or similar environment.

Their biggest concern isn’t fancy features – a capable headstock, exacting high speed spindles, helpful accessories like the right chuck and a tough tailstock ready to handle any job requirement…

Educators want to know if these machines will survive the learning curve of enthusiastic but inexperienced students.

LeBlond educational lathes are engineered specifically for this challenge, featuring:

- An Induction-hardened bed that maintains precision even after years of heavy use

- Hardened and precision-ground gears that can handle occasional shifting mistakes

- Comprehensive one-year parts and service warranty

- Lifetime technical support from a company with decades of educational experience

Why Start With Manual Machining? It’s Simple.

Industry veterans keep telling us the same story: when the CNC goes down (and it will), you need someone who can make parts manually.

One-off custom jobs? Often faster on a manual lathe than programming a CNC. Tool room operations? Almost always manual.

The manufacturing world noticed, and that’s why we’re seeing a renaissance in manual machine training over the past five years.

The LeBlond Difference: Support That Lasts Decades

With educational budgets always under pressure, schools invest in LeBlond for one reason above all others: longevity. Our equipment, like a metal lathe or milling machine, is currently teaching second and third generations of machinists in some schools.

When you call LeBlond, you’re not talking to salespeople – you’re speaking with machining experts who understand both education and manufacturing. Our dedicated service team provides:

- Comprehensive installation and training

- Technical support for both instructors and maintenance staff

- Readily available replacement parts for decades to come

- Documentation specifically designed for educational environments

Contact LeBlond For Educational Lathes

The demand for manual machinists is just beginning; manual machining fundamentals are back in demand, and LeBlond is the partner schools trust to deliver industrial-grade equipment that creates work-ready graduates.

Contact our educational specialists today to discuss how the LeBlond RKL-1332 or RKL-1340 machinery can train the next generation of versatile and skilled machinists.

- Call +1 (888) 532-5663 (Monday-Friday 8am- 4:30pm ET) and select Option 2.

- Or leave a comment below!

We look forward to hearing from you!

We purchased an RKL-1340G from you for our Tool Room and we absolutely love it. Very accurate, rugged and easy to use. I would highly recommend this machine for repairs, modifications, one off jobs… I think it would be an ideal machine to learn on as well.

Thanks Brian! We encourage you to submit a Google Review for LeBlond. It would be much appreciated.

Here’s a link:

https://www.google.com/search?sca_esv=49f8345e411de2b2&si=APYL9btvhO6SAb8jF9HqTZMMa7vs_teLnZaEVrJZwRKFIIKjoczep_MrKpsc_QmrMQozQlJnrk76wjFA782ALfLCXj2VcXarwqUO0N5hSENvT0pN7tig8pTZWCjVIaZrvdGzc1jx-5xi&q=LeBlond+Ltd+Reviews&sa=X&ved=2ahUKEwjJjPiJ6LSNAxVNQjABHe2WABYQ0bkNegQIIhAE&biw=1792&bih=974&dpr=2#lrd=0x884107c90382c535:0xc9a6846b45d4905,3,,,,