The coolant is a crucial component of the wet grinding process, as it cools and lubricates the workpiece and the grinding wheel.

Selecting the right coolant system for your surface grinder is crucial for maintaining efficient and precise grinding operations.

In this blog post, we discuss the four main types of coolant systems for K.O. Lee surface grinders and their benefits, space considerations and suitability for different applications.

Benefits of a Coolant During the Grinding Process

Here are the benefits of using a coolant on your K.O. Lee grinder.

- Heat Dissipation

Coolant fluid effectively removes heat generated during grinding, preventing the workpiece and grinding wheel from overheating. This ensures consistent performance and material integrity.

- Lubrication

The coolant reduces friction between the workpiece and the grinding wheel. This not only prolongs the lifespan of the grinding wheel but also enhances the surface quality of the workpiece.

- Chip Removal

Coolant facilitates the removal of tiny material chips produced during grinding. This helps prevent the grinding wheel from clogging and improves the overall efficiency of the grinding process.

- Enhanced Surface Finish

Coolant fluid reduces friction, leading to a finer surface finish on the workpiece. This results in a smoother and more precise finish.

- Increased Accuracy

Coolant aids in maintaining grinding accuracy by preventing overheating and ensuring the grinding wheel is properly lubricated. This contributes to more precise and dependable grinding results.

Coolant Options for your K.O. Lee Surface Grinder

Choosing the right coolant system for your K.O. Lee surface grinder can significantly impact your machine’s efficiency, precision and longevity.

Let’s detail the four options.

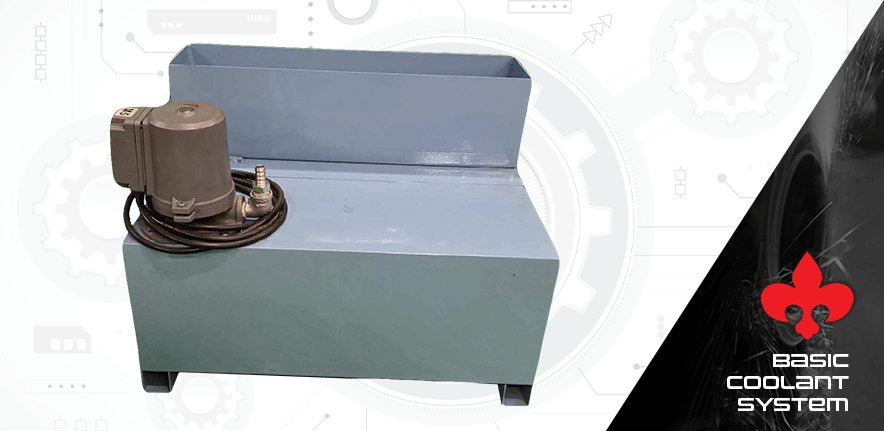

Basic Coolant System

The basic coolant system is the simplest and most cost-effective option available. This system consists of a straightforward tank and motor setup designed for wet grinding without any filtration. It’s ideal for machinists who primarily perform wet grinding and don’t require advanced filtration.

Benefits

- Cost-effective

- Simple and easy to maintain

Considerations

- No filtration, which means sediment and particles will remain in the coolant

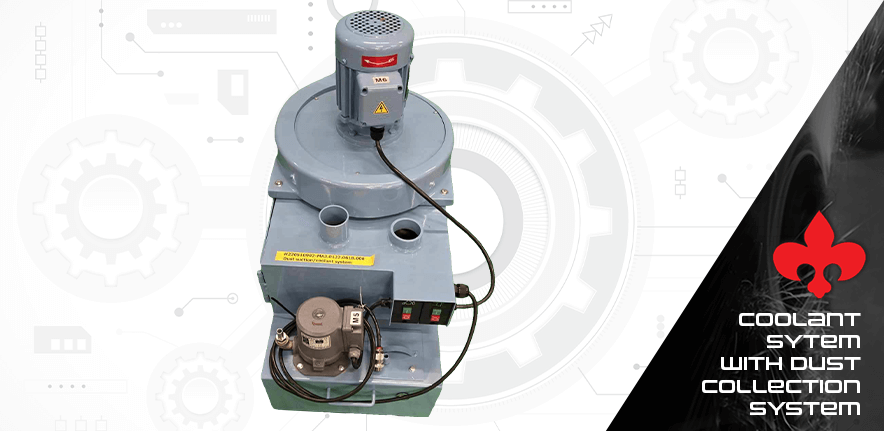

Coolant-Dust Collector Combo

For those who perform both wet and dry grinding, the coolant-dust collector combo is an excellent choice. This system combines a coolant system with a dust collector, freeing up floor space by consolidating two functions into one unit.

Benefits

- Versatile for both wet and dry grinding

- Saves floor space

Considerations

- More expensive than the basic system

- Requires more space than a standalone coolant system

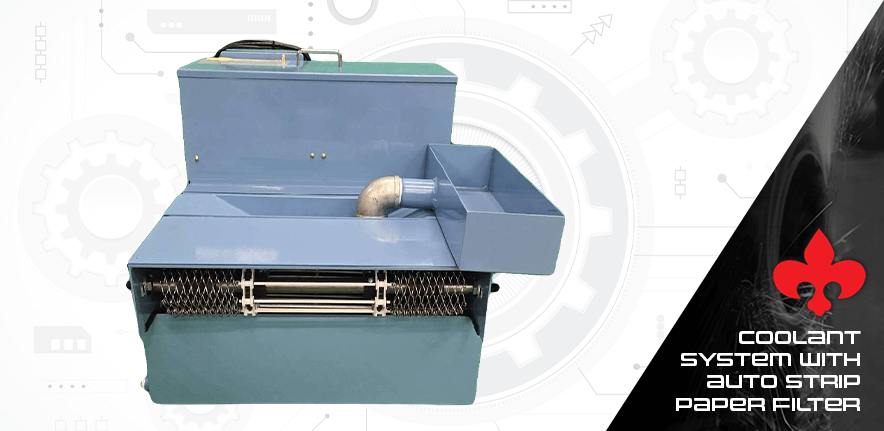

Auto Paper Strip Filter

The auto paper strip filter system adds an advanced filtration mechanism to your coolant setup. This unit is larger, occupying about 24 by 40 inches of floor space, but it effectively filters out sediment, ensuring that clean coolant recirculates through your machine. The paper filter is a consumable item and will need periodic replacement.

Benefits

- Provides clean coolant by filtering out sediments

- Prolongs the life of your coolant

Considerations

- Larger footprint

- Ongoing cost for paper filter replacements

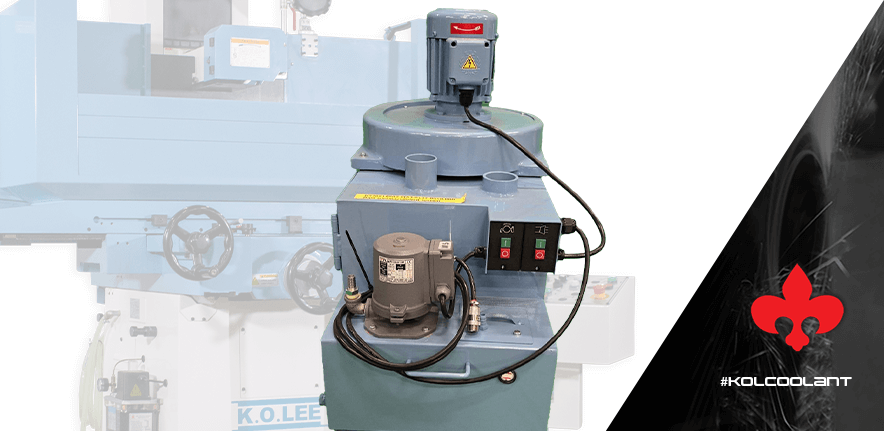

Auto Paper Strip Filter with Magnetic Separator

For the ultimate in coolant filtration, the auto paper strip filter with a magnetic separator is the best option. This system includes a magnetic separator that removes metal particles from the coolant, reducing the load on the paper filter and extending its life.

Benefits

- Superior filtration with magnetic separation

- Extends the lifespan of the paper filter

Considerations

- Most expensive option

- Requires space for both the filter and magnetic separator

Choosing the Right K.O. Lee Coolant System

When selecting a coolant system for your K.O. Lee surface grinder, consider the following factors:

- Application

Determine whether you’ll be performing wet grinding, dry grinding or both. Wet grinding necessitates a coolant system, while dry grinding may benefit from a dust collector.

- Space

Evaluate the available floor space in your shop. Combining units can save space, but larger systems like the auto paper strip filter will require more room.

- Budget

Basic systems are the least expensive, while advanced systems with filtration and magnetic separation will cost more. You need to balance your needs with your budget.

- Maintenance

Consider the maintenance requirements for each system. Systems with filters and magnetic separators will require regular upkeep to ensure optimal performance.

Additional Accessories for Your Surface Grinder

In addition to picking the right coolant system, consider investing in a backwater splash shield if you plan on doing a lot of wet grinding.

This accessory helps contain the coolant, preventing it from splashing behind the machine. It keeps your workspace cleaner and safer.

Final Thoughts: Choosing the Right Coolant System for your Surface Grinder

Choosing the right coolant system for your K.O. Lee surface grinder is a critical decision that can greatly impact your grinding operations.

From basic systems to advanced options with filtration and magnetic separation, each type of coolant system offers unique benefits tailored to different needs and applications.

Interested in a new K.O. Lee surface grinder?

Don’t forget our summer sale where you can receive up to 10% off new LeBlond and K.O. Lee equipment.

- Call +1 (888) 532-5663 and select Option 2 (Monday – Friday 8am – 5pm ET).

- Or just leave a comment below.

We look forward to hearing from you!

Hello,

What is your price range for your different coolant systems for surface grinders?

Basic may be the way to go if other prices are too much, but have filtration would be nice. I mainly do steel at the moment, and it’s not a high production or even a standard production machine. Mainly a “I have it for when I need it.” But I’m not too keen on a pump in a bucket of coolant either. Kind of a disaster waiting to happen(spillage).

I have been using a synthetic oil, so I kind of like the idea of your combo machine so I can actually separate the wheel dust when dressing. I’m still a pretty new business with not a ton of an expendable cash, so as mentioned, the basic system may be all that’s in my budget.

Thanks in advance,

William

Thanks for your query, William. Someone will contact you. For immediate service, call 888-532-5663 and select Option 2.