Table of Contents

- LeBlond CNC Lathe Machine Overview

- Applications of CNC Lathes

- LeBlond CNC-1540 Features

- LeBlond CNC Lathe Headstock

- CNC Machine Tools Standard Accessories

- Optional LeBlond CNC Lathe Accessories

- LeBlond CNC Lathe Machine Benefits

- Factors to Consider While Choosing a CNC Lathe

- OK Computer Lathe

We do now! LeBlond is introducing the CNC-1540 Teachable Precision CNC Lathe, which continues the LeBlond tradition of reliability in machine tools at an affordable price point.

LeBlond CNC Lathe Machine Overview

Our machine is a 2-axis CNC lathe. Unlike a manual lathe, the LeBlond 2-axis CNC lathe can be programmed for the material or workpiece to be held in place and rotated by the main spindle. The cutting tool is mounted and moved on various axes to engage the workpiece for facing, turning, drilling or tapping operations.

Before diving into LeBlond’s CNC lathe features and benefits, let’s get down to basics on CNC lathes or Computer Numerical Control machines.

Applications of CNC Lathes

A CNC lathe slowly shears off materials from the workpiece, resulting in precise, finished products or complex parts. Since the equipment is flexible, many industries like automotive, electronics, and aerospace use these machines.

A CNC multi-axis CNC lathe produces plane surfaces and screw-threaded pieces. In the case of elaborate CNC lathes, a machine shop can produce 3-dimensional components whose complexity varies widely depending on how the lathe is constructed.

CNC lathes are very accurate for smaller workpieces and large ones. Usually, the workpiece holds its position in a single or CNC turning center. A machinist can also attach collets or cling clamps to hold the workpiece, if necessary.

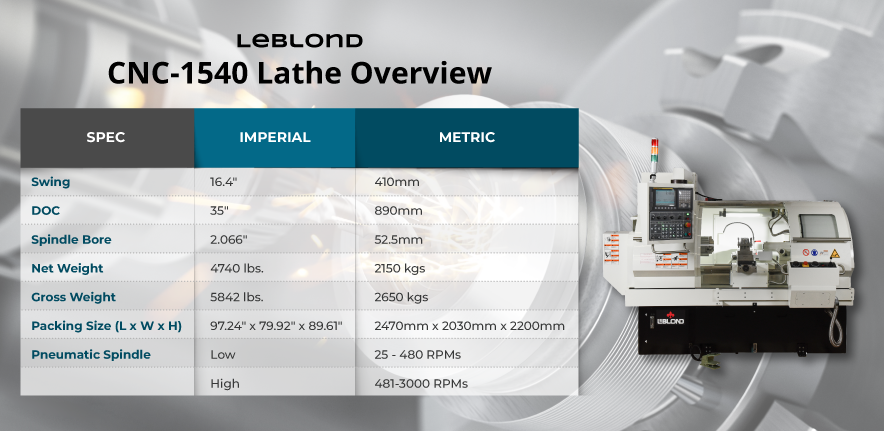

LeBlond CNC-1540 Features

Our model is an entry-level CNC lathe for hobbyists and professionals alike.

It features:

- A large 16.4″ (410mm) swing

- 35″ (890mm) between centers.

- A 2.066″ (52.5mm) spindle bore

- Pneumatic spindle change steps of between 25-480 RPMs at the low end and 481-3000 RPMs at the high end.

LeBlond CNC Lathe Headstock

The gears are hardened by MAAG or REISHAUER premium gear-grinding technology for smooth, quiet, and vibration-free running.

The headstock on the CNC-1540 features pressurized cyclic lubrication from an electric pump and oil reservoir for constant flow in gears and bearings. The hot oil does not stay in the headstock, mitigating thermal expansion and workpiece intolerance.

A 4-parallel V-belt assures drive is stable and smooth with minimum vibration during the machining process.

CNC Machine Tools Standard Accessories

The LeBlond CNC-1540 comes with

- A Fanuc CNC controller

- Hydraulic Tailstock Quill

- 8” Hydraulic Chuck

- Electric H4 Turret

- A Rotating center MT.4

- Level pads (8 pieces)

- A toolset and box

- A machine light

- An operation manual and parts list

Optional LeBlond CNC Lathe Accessories

Add-ons include but are not limited to

- 3-jaw scroll 8″ chuck

- 4-jaw independent 10″ chuck

- Hydraulic P8 Turret

- Quick change tool post

- Steady rest with ball bearing

For complete accessories or pricing on the CNC-1540, call LeBlond at +1 (888) 532-5663 and select Option 2.

LeBlond CNC Lathe Machine Benefits

- CNC turning machines like the LeBlond CNC-1540 allow the machining of redundant workpieces quickly and efficiently

- Manufacturing processes are made easier by automation driven by a myriad of complex commands and speed rate instructions inputted on the controller and driving CNC turning centers, the rotating spindle and other machine components

- Easy to program with Computer-Aided Design (CAD) languages

- Get one-stop shopping for parts, service and other LeBlond machine tools like mills, band saws and drill presses

Factors to Consider While Choosing a CNC Lathe

Now that you know more about our CNC lathe, here are some considerations when deciding on a machine.

Number of Axes

The LeBlond CNC-1540 has 2-axis linear axes suitable for various turnovers. This lathe machine also offers manual control for the X and Z-axis. It features a movable operation control box equipped with two electronic handwheels.

The Machine Footprint

The footprint is the space the machine occupies. First, you must consider where you want to install the machine, like a personal workshop or industrial setting.

The LeBlond CNC-1540 has a net and gross weight of 4740 lbs. (2150 kgs) and 5842 lbs. (2650 kgs), respectively. The packing size is 97.24” (2470mm) in length, 79.92″ (2030mm) in width and 89.61″ (2200mm) in height.

Larger CNC lathes generally need more power. On other CNC lathes, it’s necessary to consider whether the machine can handle the outer diameter of the intended workpiece.

Cycle Time

The cycle time is the period when a lathe performs its operations like cutting the outer diameter of a workpiece. Machines with longer axes have shorter cycle times and greater efficiency. You determine cycles based on production requirements and production time constraints. It’s recommended to use CNC cutting tools in industrial settings where the number of parts to be machined is greater. If the production rates of your business are smaller, cycle timing may be less important. If this is the case, a CNC lathe can still save you time and money compared to manual lathe operations.

Power And RPMs

The spindle motor speed and spindle rotation rate determine which material will be used for turning, screw-cutting and helical milling operations. Some machines have one speed and others have variable speeds with torque and speed on a range.

Torque allows heavy pieces to rotate on the axis with more force, helping facilitate cuts. Metal workpieces require higher RPMs to keep optimal cuts. Cutting threads on metal pieces require a robust motor at low RPMs.

Materials

You should take into consideration the type of materials in a workpiece. Turning metal requires high precision but very minimal tolerance requirements. CNC lathe machines can create parts with tolerances up to 0.00005”.

Controller And Software

A machinist programs a software controller to drive a CNC turning center movements. The controller and computer system’s application software should be examined for file types. Lathes with a CNC turning center can be programmed with proprietary or open-source software. Proprietary software offers more features and is easier to set up with greater technical support. These models, however, are more costly. The LeBlond CNC-1540 features waterproof function keys and push buttons to increase programming convenience.

OK Computer Lathe

LeBlond, a company dating to the late 19th Century, spearheads the modern era of machine tools with the CNC-1540. If you have questions on this machine or would like pricing, please call us at +1 (888) 532-5663 Monday – Friday 8am – 5pm Eastern.

We look forward to hearing from you!

What is the price ?

Danny, thanks for reaching out. Someone will contact you regarding pricing on our new CNC lathe. For immediate service, call (888) 532-5663 and dial Option 2.

what is the price for a hobbyist?

Gary, thanks for reaching out. Someone will contact you regarding pricing for our CNC lathe. For immediate service, call (888) 532-5663 and select Option 2.

May I have a budgetary quote and availability, please?

Jim, thanks for reaching out. Someone will contact you regarding a quote and availability. For immediate service, call 888-532-5663.