Stay Safe, Machine On, With These Lathe Safety Tips Most safety precautions machinists take today are a result of someone learning from a past mistake or oversight. Those lessons are passed down from old-timers to green newbies, as well as through industry...

Tips

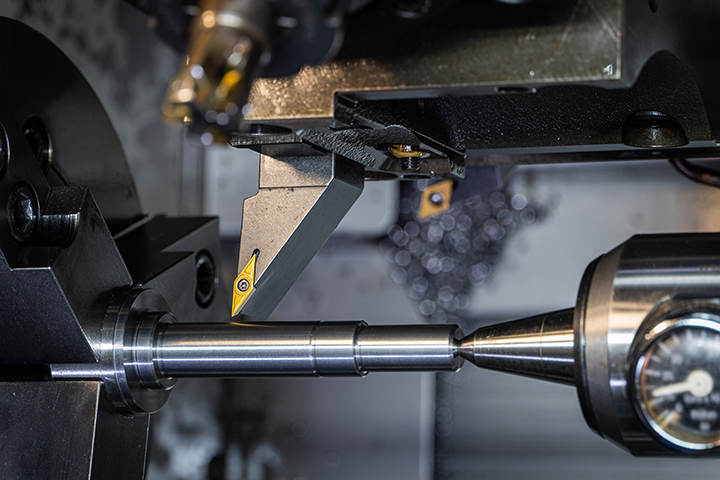

5 Telltale Signs of Tool Wear Every Professional Machinist Should Recognize

Signs of Tool Wear Machinists strive for perfection in every cut. Even the slightest deviation in precision metalworking can mean the difference between a flawless part and costly rework. Tool wear is inevitable, but early detection and correction can save valuable...

Mastering Machining Feeds, Speeds, and Depth of Cut

Don’t Get Haunted by Flawed Lathe Practices Even the most experienced machinist can be haunted by ghosts of poor performance — chatter marks that refuse to vanish, overheated tools that wear out too soon, or parts that just won’t meet spec. In the spirit of Halloween,...

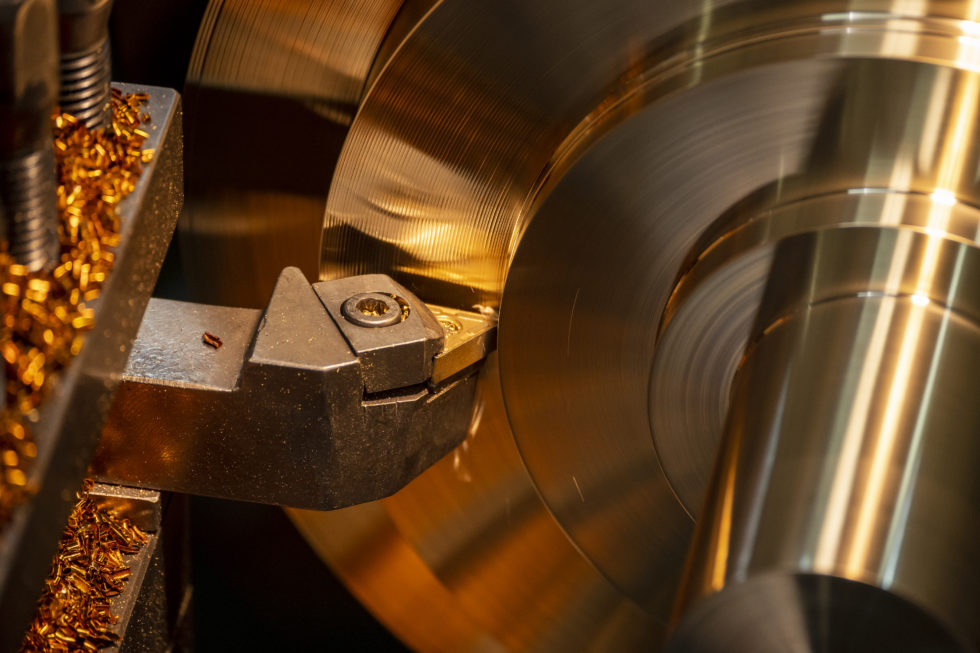

Your Cuts Look Like Garbage. Here’s Why.

You fire up your lathe. Load your workpiece. Make the cut. And it looks like someone dragged a jackhammer across the surface. Welcome to chatter marks. The universal sign that your gibs are shot. Most machinists don't think about gibs until it's too late. They blame...

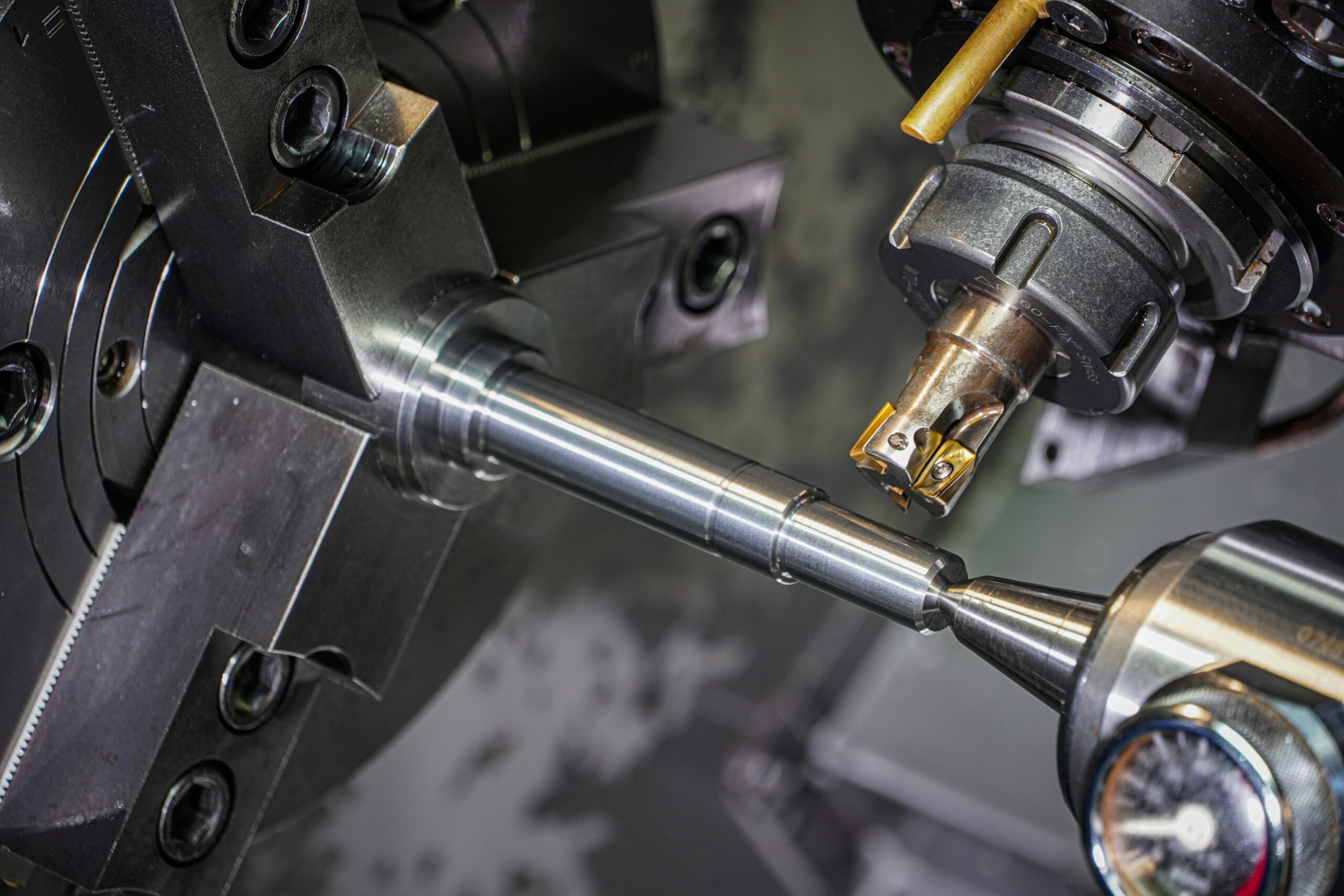

5 Tips to Manage Tool Overhang in Lathe Metalworking

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

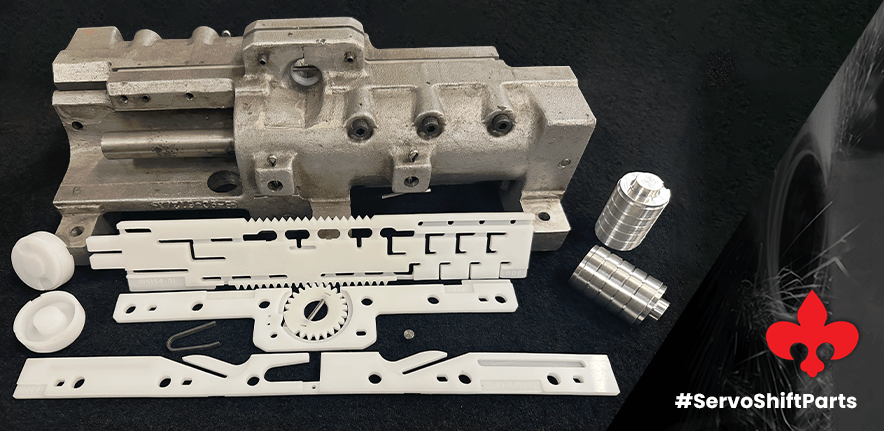

The Servo Shift Design Flaw Nobody Talks About

LeBlond engineers made one catastrophic material choice in the 1960s. Nylon seemed perfect for servo shift components. They were dead wrong. Every machine owner has been paying for it ever since. That clicking sound coming from your Regal? It's nylon disintegrating at...

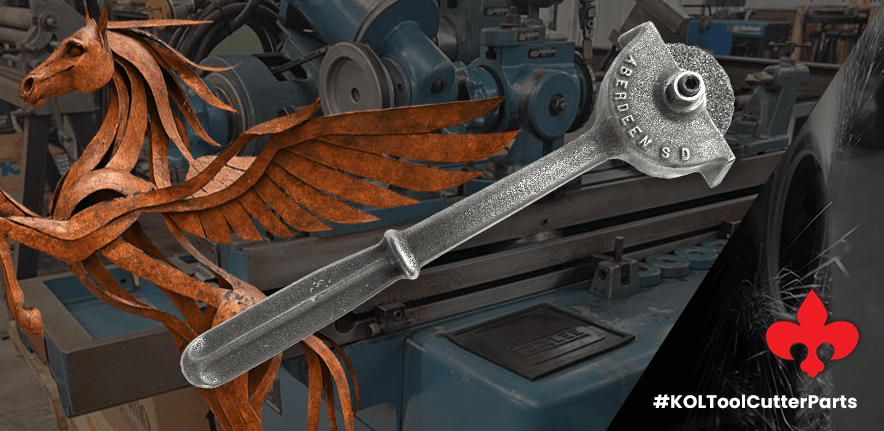

Keep Your K.O. Lee Tool & Cutter Grinder Running Like a Beast

Your K.O. Lee tool and cutter grinder is a precise monster of a machine. It's built to sharpen end mills, cut gears and handle demanding tooling work day after day. But like any workhorse, it needs the right parts to keep performing. When critical components...

Lathes Get Machining Done

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

7 Essential Lathe Maintenance Tips for Smooth, Accurate Machining

A well-maintained lathe doesn’t just run better—it lasts longer, performs more accurately, and reduces downtime. Whether you’re operating a manual machine or a CNC lathe, implementing a structured maintenance routine is critical.