Your old lathe is bleeding money. Every second you spend squinting at grimy Vernier dials is profit walking out the door. The Newall NMS 800 Digital Readout changes everything. No more guessing. No more mistakes. Your Current Setup is Killing Productivity Cross-slides...

News

LeBlond Christmas Cards That Save You Major Cash!

We have cards. We have Christmas cards. We have Christmas cards celebrating an in-stock machine sale! These are cards a shop machinist can send to their buyer or procurement specialist, asking for much-needed equipment at a discounted price before year’s end. To recap...

Need Parts? Check Out Our Christmas List!

Need LeBlond, K.O. Lee, Standard Modern, Deka Drill or Johnson Press parts? Then contact LeBlond by year's end and get a substantial discount. We’ll fill you in on the exact percentage off when you call or fill out a parts request form. To celebrate this sale, we...

LeBlond’s In-Stock Machinery Sale Is All Math & Miracles

LeBlond has a 12% off in-stock machinery sale to close out 2025. Why twelve? Because twelve is perfect. Literally. It's one of only two perfect numbers in mathematics under 30. It's divisible by 1, 2, 3, 4 and 6. Twelve apostles. Twelve tribes of Israel. Twelve...

Spin the Wheel & Win Big on Machine Tool Parts

Forget Pat Sajak. This isn't your grandmother's game show. LeBlond is turning parts procurement into a high-stakes game where machinists win the most. Call us or submit an online quote request to reveal your mystery discount percentage on genuine parts for LeBlond...

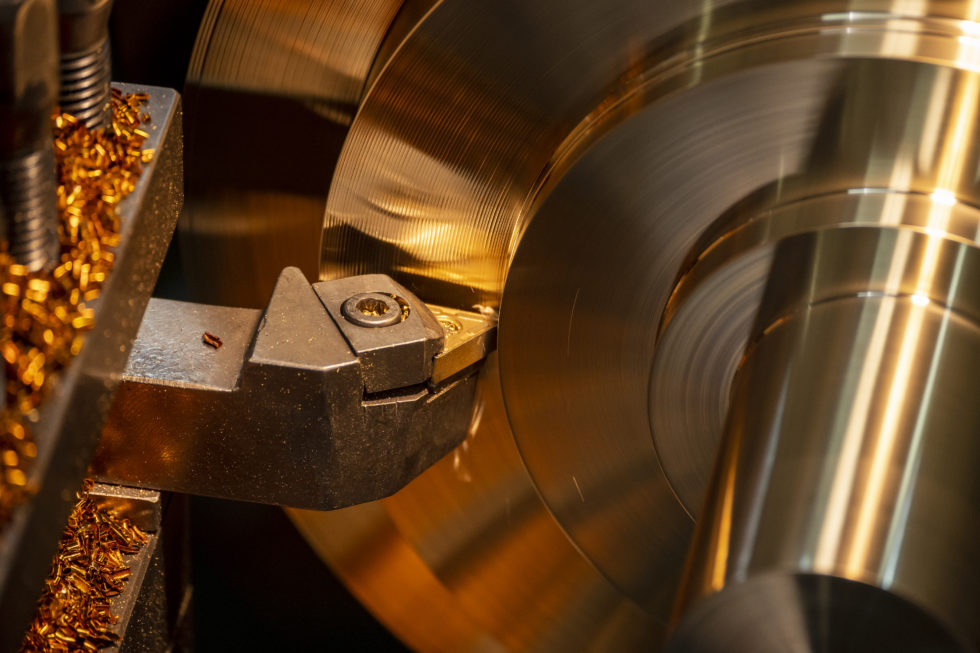

5 Tips to Manage Tool Overhang in Lathe Metalworking

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

Lathes Get Machining Done

Complex machined parts often require multiple steps for turning, boring, facing and finishing for final part production or assembly. Thankfully, lathes can handle many of the different cutting processes from start to finish.

LeBlond In-Stock Machines Are a Winning Hand

An in-stock LeBlond machine is the best card for Phil to play, even if he doesn’t realize he is gambling. Phil is a machinist who supplies parts for the automotive industry. Uptick in Business? He expects business to pick up with a flurry of recent trade deals,...

7 Essential Lathe Maintenance Tips for Smooth, Accurate Machining

A well-maintained lathe doesn’t just run better—it lasts longer, performs more accurately, and reduces downtime. Whether you’re operating a manual machine or a CNC lathe, implementing a structured maintenance routine is critical.